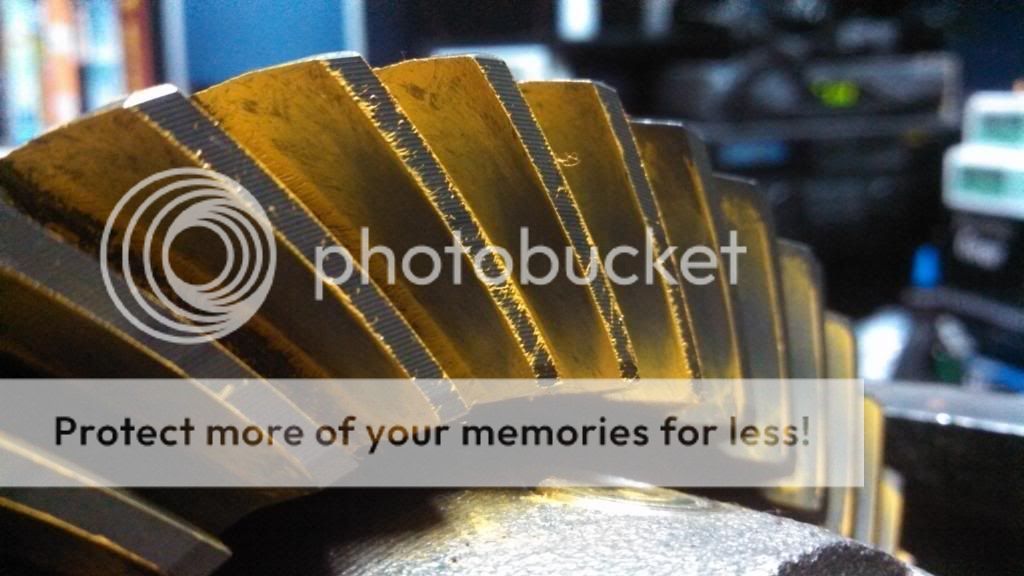

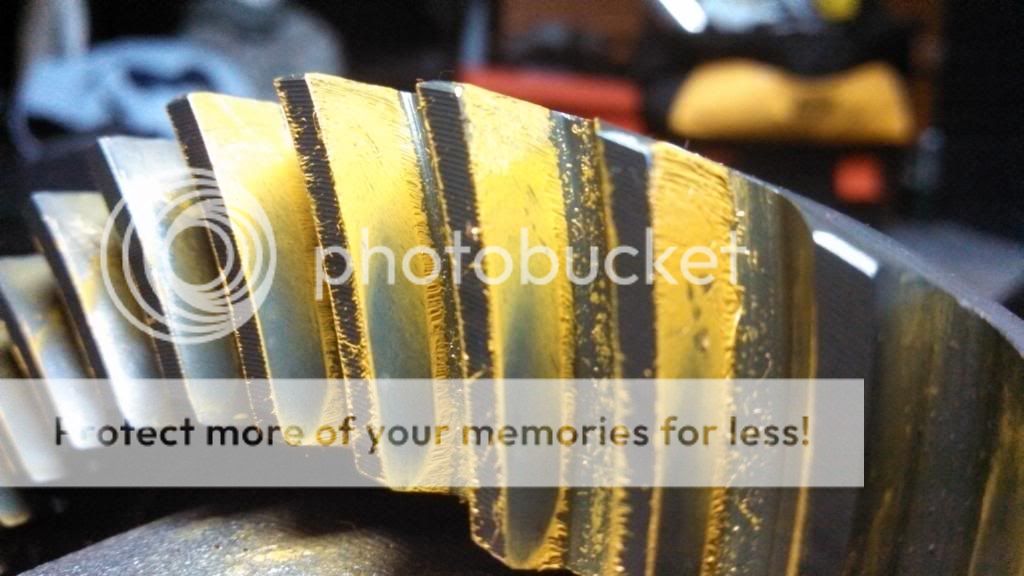

Too shallow: the pinion is too far away from the ring gear. Usually causes the pattern to appear out at the heel (outer edge)

Too deep: Pinion is too close to the ring gear. Usually causes the pattern to appear at the toe (inner edge)

Also when the pinion depth is not correct, one or both of the patterns will have a feathered look to them, exactly like your last set of pics.

I'll admit, even the one's above I gave the "ok" on could look better. IMO the pinion is much too deep.

A little advice on us helping you.. When speaking of the pinion shims, include the thickness of the slinger and any other oil dams in place in your shim total, as they too add to the total amount of distance the pinion is off from the master housing depth.

Most all of the D30's I have set up have fallen in between .070" to .080" total. One or two at .065"-.068"

They don't vary too much, and if I find one that won't fall into a really nice pattern with the typical amount of shim, the housing is warped.

You also might try to bring your backlash closer to .010" as aftermarkets tend to hone their gear sets wider than the OEM sets. Don't get too hung up on FSM specs as you are not dealing with OEM gears.

Don't feel bad and don't give up. I even run into troublesome ones that don't fit the standard setup and without the proper tools to at least give you a starting point, it can be tough to dial in a set of aftermarket gears. I've strove to get a pattern perfect when sometimes 'good enough' is just that, and the gearset ends up running just fine with no future problems.