JeremyB

NAXJA Forum User

- Location

- Senoia, GA

Do you think you could get the Vortec mechanical fan in between the radiator & motor?

Also -

Consider cutting & "stretching" your gauge wires so you can run the Jeep PCM under the dash somewhere, using one of the factory wiring passages. Use solder for the splices and you won't mess up your signals. Might not be worth the effort but it would get the Jeep PCM & some of the wiring out of the engine bay.

I'm jealous of this thing already. Someday, someday...

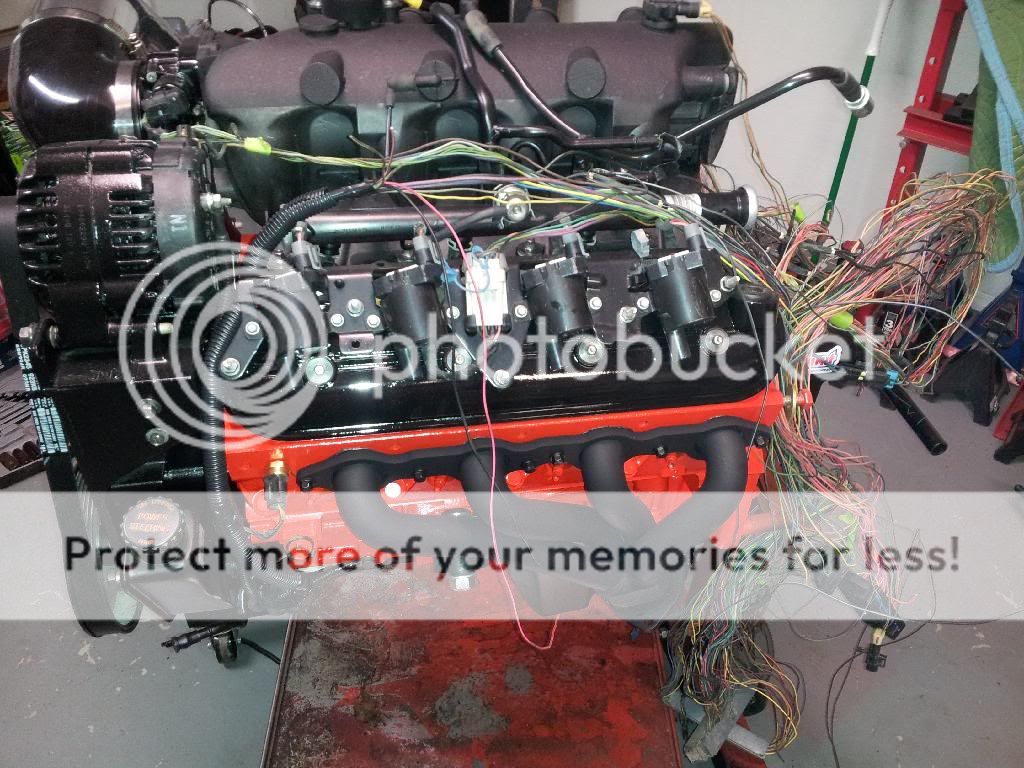

Definitely not enough room to use the GM fan. I'm in the proses of trying to remove the Jeep PCM completely from the harness then make it a remote stand-alone with only the VSS, tach, oil, water, power, fuel level and ground inputs.