Demolition_x

NAXJA Forum User

- Location

- Toms River NJ

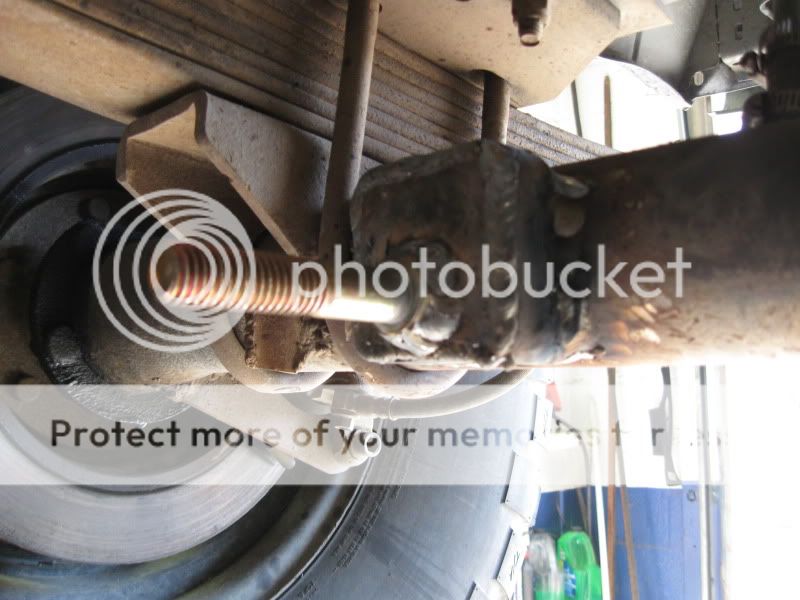

I am having a hard time deciding how I want to relocate my rear shock mounts on the axle. I have installed shackle relocation brackets and now my shocks are a little too short. I was thinking about using just regular tabs and mounting them above the axle similar to this...

Will I have any problems mounting them on top of the axle versus having them alternating on either side of the axle like the stock set up.

I heard that the stock mounts (alternating on either side of the axle) helps eliminate axle wrap but I am not so sure if it really effective or not.

If anyone has mounted there shocks above the axle like above is there any downsides?

Will I have any problems mounting them on top of the axle versus having them alternating on either side of the axle like the stock set up.

I heard that the stock mounts (alternating on either side of the axle) helps eliminate axle wrap but I am not so sure if it really effective or not.

If anyone has mounted there shocks above the axle like above is there any downsides?