So I finally had time to wrench on the Jeep. Got the engine all put back together, most of it installed and ready to go. Just have to install my radiator, ps pump, distributor and a few other things. I got all my old parts and I'm trying to make sense of it all. Like I said, I know driving on steep inclines can cause oil starvation problems but how is it that I'm the only person who's ruined a engine by wheeling it...I find it kind of hard to believe but I suppose anything can happen. I checked out the oil pump and tube and it was pretty tight. I started to think, hey maybe it was loose but I guess it wasn't after I checked. The fitment to the block looked pretty nice too, the old gasket looked evenly compressed also. Well if all goes well I should be able to fire it up tomorrow. Can't wait to have my Jeep back on the road! Here are some pics of the carnage...maybe you've seen this?

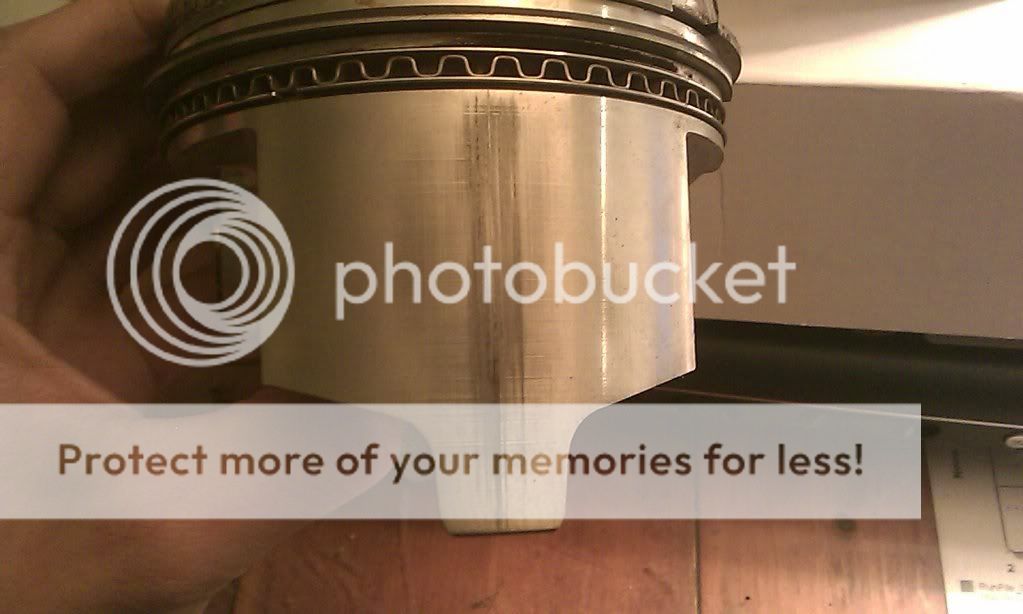

What I say is typical wear in a engine, ok maybe not ideal but nothing I haven't seen thats caused any issues...what was a bran new piston with 25,000 miles on it.

Now the OTHER SIDE of the same piston...

These are 3 different parts of the connecting rod bearings...

This is what only 2 of the 4 camshaft bearings looked like, I believe the center 2 are the wasted ones and the 2 outers were ok.

I noticed 3 bearings had 1 hole from the oil galley but 1 bearing had 2 holes, also some had a manufactured groove and some (or just 1) were compleatly smooth. Any one know why they are different? I'm sure if those were in the wrong order when they were installed I'm sure that could have caused a problem but since I didn't remove or install them I wouldn't know for sure if they were in there correctly. :doh: