So I just brought these guys home.

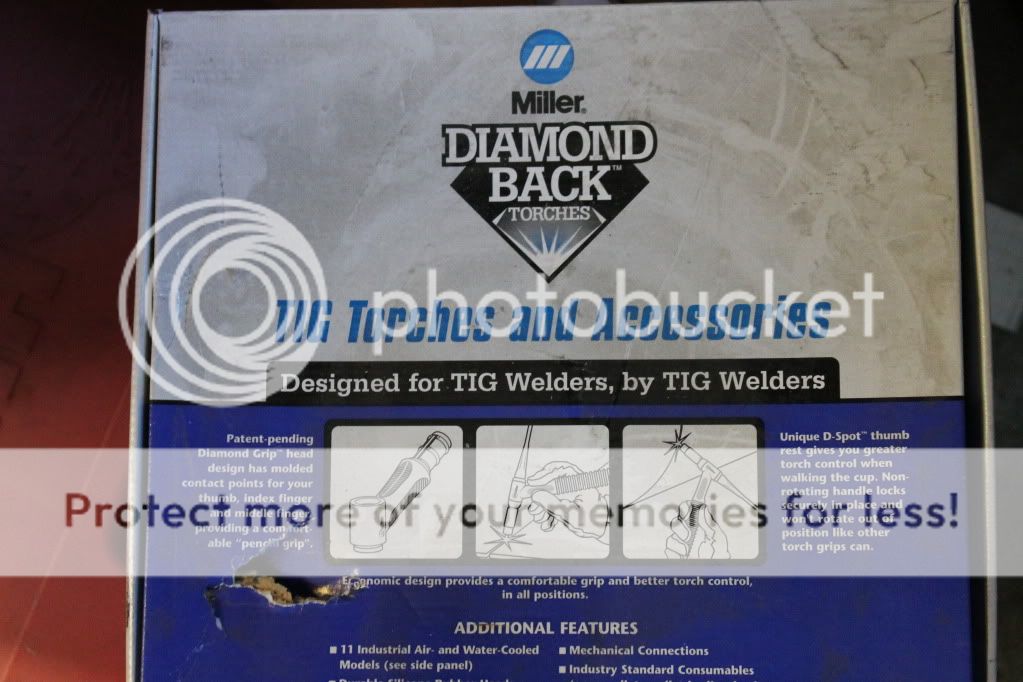

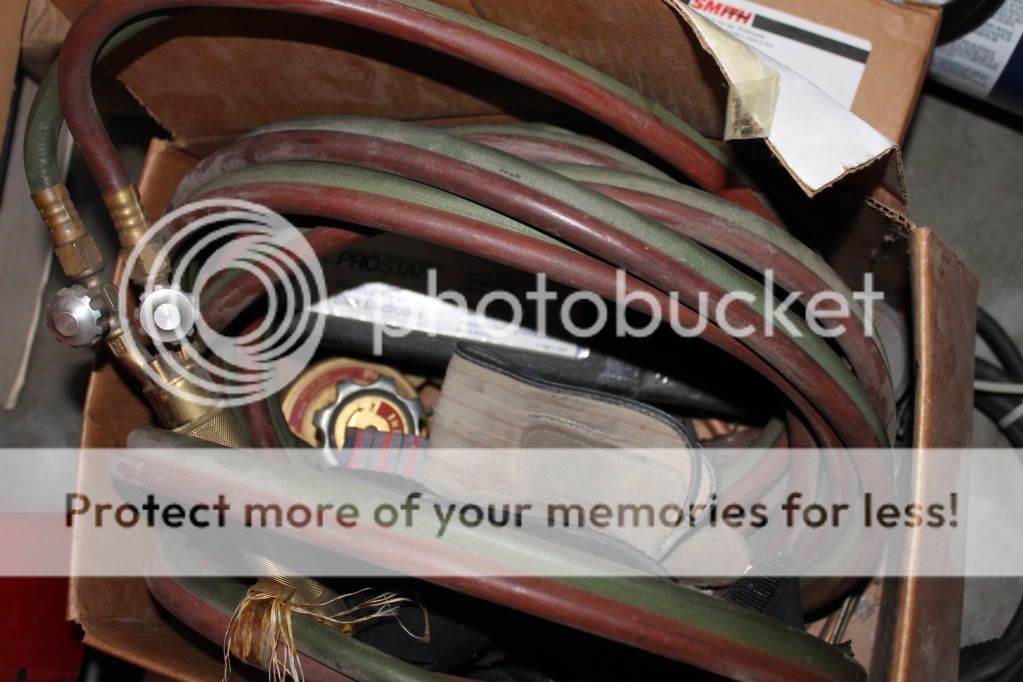

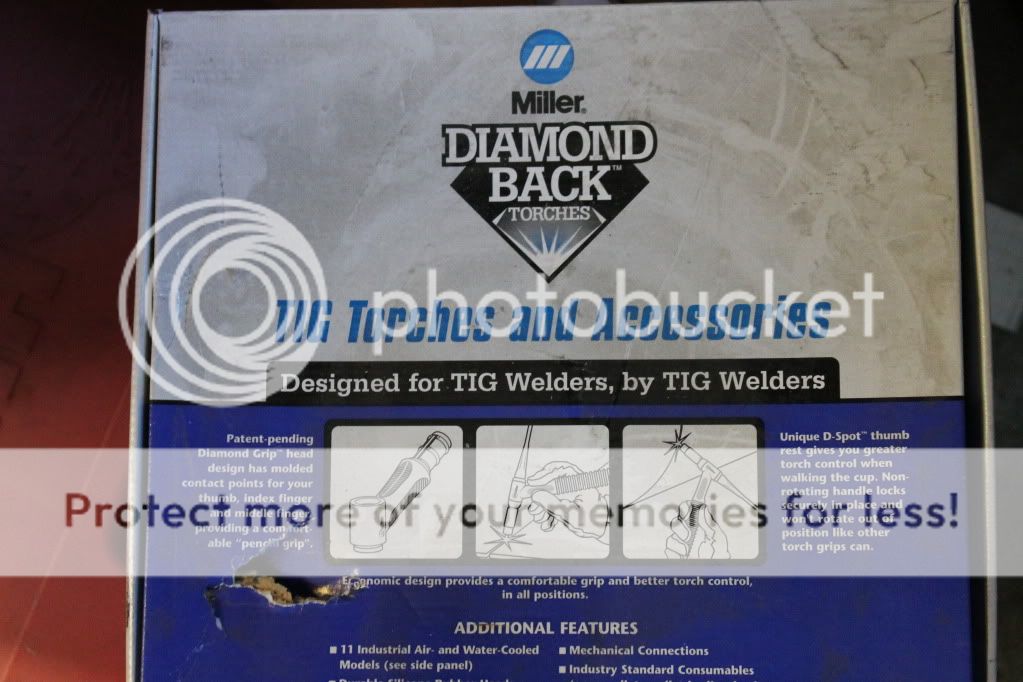

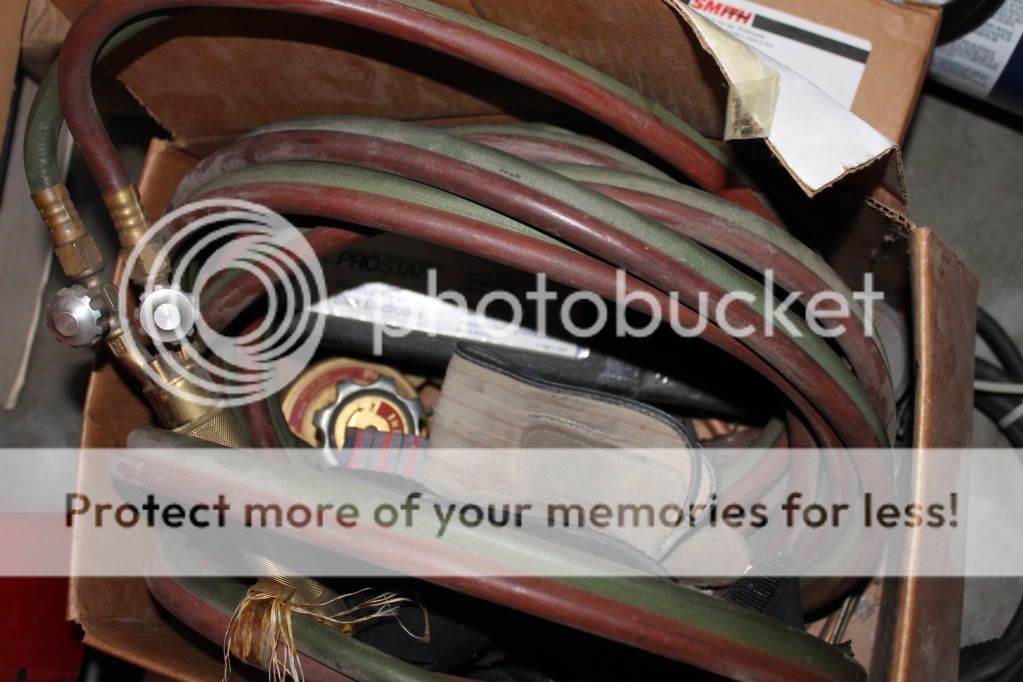

So I know that the buzz box is a TIG/Stick machine but thats about it. Is anybody familiar with this machine/tig torch? Now we need bottles for Argon, Oxygen, and Acetylene.

I know I need 100% Argon for the TIG welder. Can I use the same 100% Argon for MIG welding instead of a 75/25 argon/CO2 mix? I have an itty bitty 110v MIG I will be using for now.

Is it possible to get a large tank of 100% argon and somehow mix it with the gas from a smaller CO2 tank to get the 75/25 mixture?

So I know that the buzz box is a TIG/Stick machine but thats about it. Is anybody familiar with this machine/tig torch? Now we need bottles for Argon, Oxygen, and Acetylene.

I know I need 100% Argon for the TIG welder. Can I use the same 100% Argon for MIG welding instead of a 75/25 argon/CO2 mix? I have an itty bitty 110v MIG I will be using for now.

Is it possible to get a large tank of 100% argon and somehow mix it with the gas from a smaller CO2 tank to get the 75/25 mixture?