I have had quite a bit of success fixing these boards and I have had some people reach out recently (after finding this post) asking for details on how to fix theirs so I thought a write-up might be in order. I will also place a parts list near the bottom.

The Problem

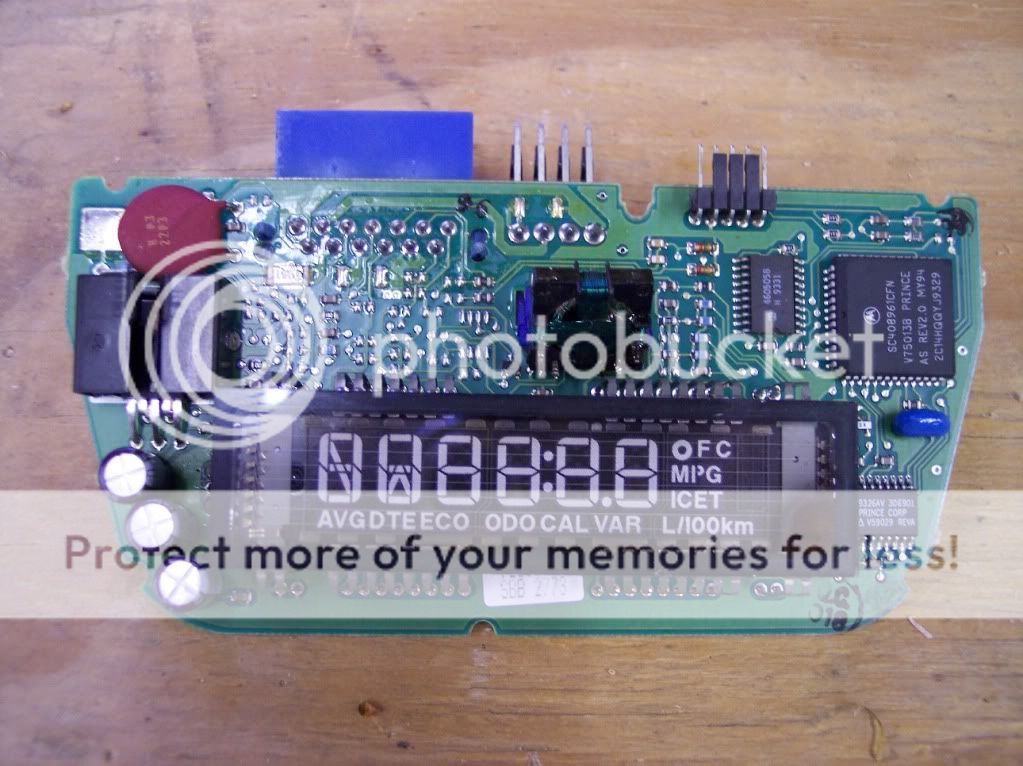

First, the area that typically gets fried sits around a 5volt regulator which is highlighted with a white arrow in the picture below. From what I am seeing, the cause of failure always seems to be one (or all) of the electrolytic capacitors highlighted in the blue boxes. This makes sense because electrolytic capacitors tend to last a LONG time but what can kill them is heat and sitting next to the roof of an XJ for 20 years is a pretty sure way to accelerate their demise. The problem is that when they blow, they take other components (and traces) with them. The 3 small ceramic capacitor to the right of the voltage regulator (numbered 1-3 in orange)are prime targets for this. These 3 capacitors can actually be removed since they aren't really needed in this circuit but I will include a section below on how to change them out if you prefer.

Power Circuit

The real issue is that when the electrolytic capacitor blows, these little caps get really hot and often cause some of the traces to break. The one highlighted in red is often bad and this one is very important since it is what provides the ground signal to two of the electrolytic capacitors. To test this, turn the board over and connect a mult-imeter (set to ohms) between pin 3 of the regulator and the negative pole of each capacitor (marked with the white bar and a "-" sign on the sides of the capacitors). When you connect your meter to these points, each should read close to 0 ohms.

CPU Reset Circuit

The other trace that tends to get burned up is the one that connects pin 2 of the regulator to the CPU. This pin provides a 4.6-4.7v reset signal to the CPU and if it is broken, the CPU won't turn on. The best way to check this trace is to use your multi-meter again (still on the ohms setting) between pin 2 of the regulator and pin 5 of the CPU (both ends highlighted with the yellow arrow). When you connect to these you should also get a reading of close to 0 ohms.

The Fix

If both of your multi-meter tests are good, you should be able to simply replace these three capacitors. All 3 are 100uF 35V capacitors and are available online or from places like Fry's Electronics. Typical cost is ~$1.50 each (3 needed).

Power Circuit fix

If you found a broken trace between pin 3 and the negative poles of the electrolytic capacitors, the easiest fix is to turn the board over and solder a wire between pin 3 (ground) of the regulator and the negative pole on one of the new electrolytic capacitors. This essentially re-attaches the connection I highlighted with the red line in the pic. Here is an easy trick: rather than looking for small wire, simply use some of the excess wire you will cut off the bottom of the capacitors and slide some heat shrink tubing over it. This will insulate the wire to keep it from touching any other part of the circuit.

CPU Reset Circuit fix

If you found a broken trace when you checked the connection between pin 2 of the regulator and pin 5 of the CPU, the fix is a little harder. The break is usually on a small trace that runs right between the orange 2 and 3 in the pic. If you look closely at the pic, there is a small solder spot directly under the orange number 3. What this hole does is connect the trace on the top of the board to another trace on the bottom of the board. If you connect your multi-meter between this solder blob and pin 5 of the CPU, it should read 0 ohms and if so, I typically turn the board over, heat up this blob and feed a small wire through it. I then attach the other end of the wire to pin 2 of the regulator (using heat shrink insulator again).

Burned up ceramic capacitor fix

This fix isn't really necessary since the board will work perfectly without these capacitors but if anyone wants to change them out, they are all 100nF and can be replaced on the backside of the board with traditional ceramic capacitors. These cap's are simply used to try to protect the voltage regulator when something goes wrong. I have numbered them in the pic and the connect as follows:

#1 - connects between pin 3 of the regulator and the positive side (opposite of the side marked with the white bar and "-" sign) of the middle electrolytic capacitor.

#2 - connects between pin 2 and pin 3 of the regulator

#3 - connects between pin 3 of the regulator and the

positive side (opposite of the side marked with the white bar and "-" sign) of the right-most electrolytic capacitor.

Test

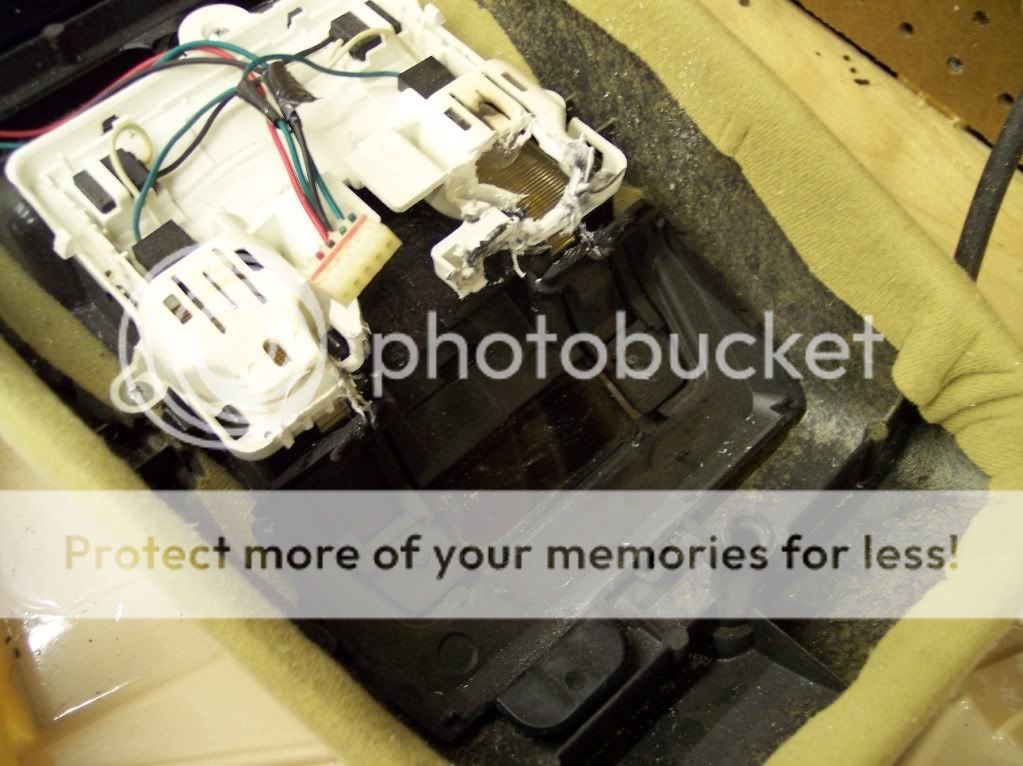

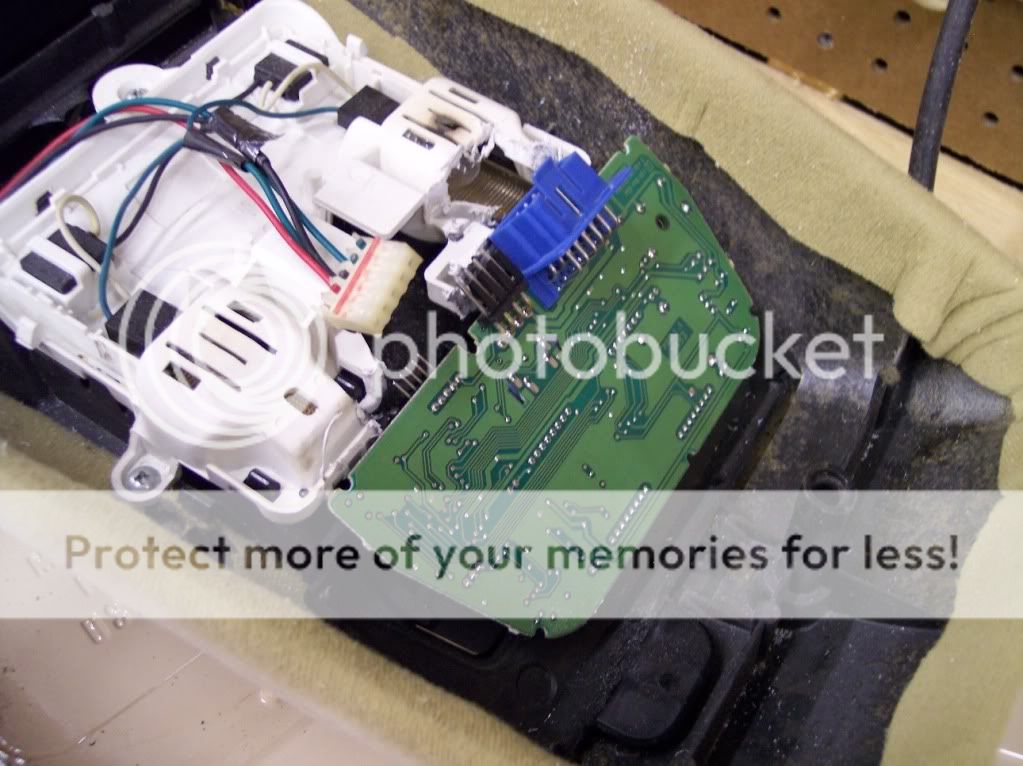

Once you have done all this, you can reinstall in the Jeep and check that it is working. Alternatively, if you have a 12volt power supply available, you can connect power to pin "1" and ground to pin "e" to test the circuit on the bench. Note that you may have to press the "Comp/Temp" button to turn it on.

a b c d e f - this side is towards the center of the board

X X X X X X

X X X X X X X

1 2 3 4 5 6 7 - this side is towards the center of the board

Parts list

Parts list

(3) 100uF 35v Electrolytic capacitors - ~$1.50 each at Fry's Electronics or Radio Shack

http://www.radioshack.com/product/index.jsp?productId=2102510

(1) L487 5volt regulator - ~$5.00 on eBay (probably not needed since this regulator can take a LOT of abuse.)

(3) 100nF ceramic capacitors - $0.62 each not really needed

http://www.radioshack.com/product/index.jsp?productId=12401429

Tools Required

a half decent soldering iron is required - ~$10.00

http://www.radioshack.com/family/index.jsp?categoryId=2032313&sr=1&origkw=soldering%20iron

some solder

http://www.radioshack.com/product/index.jsp?productId=2062719

a vacuum desoldering tool comes in handy - ~$10.00

http://www.radioshack.com/product/index.jsp?productId=2062745