blistovmhz

NAXJA Forum User

- Location

- Vancouver, BC

98 XJ, 6.5" long arm, shackle relocation + 6" shackle.

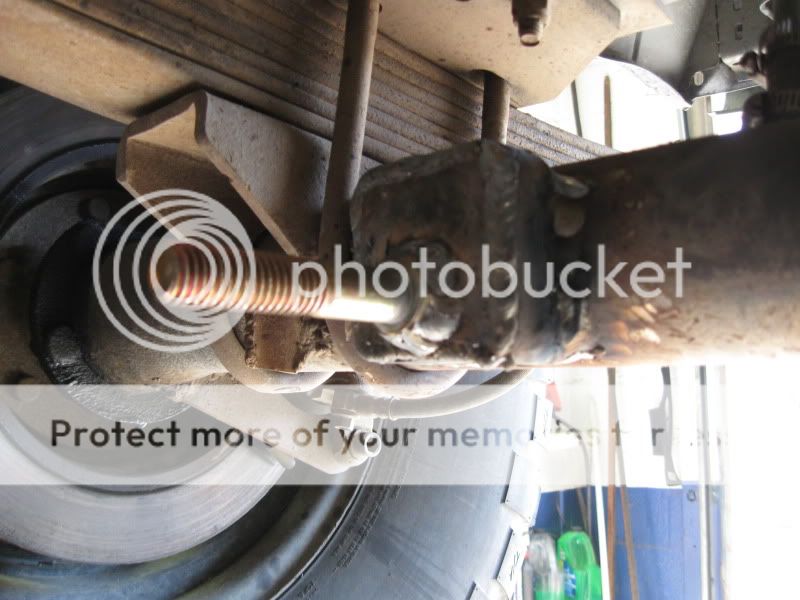

Just installed my D44 which has the shock mounts mounted flush with the axle (no drop). Because of the shackle drop and 6" shackle, my pinion points exactly at the t-case, so the axle is leaned back quite a bit. So now the shock mounts that normally point straight out, are now pointing down the driver side and up on the passenger side.

Drivers side mount is 0.5" below axle center while passenger side is 0.5" above. This only leaves 4" up travel on the drivers and 3" on the passengers, and this ain't sufficient.

This is where I'm getting confused. With 31" rubber, 6.5" lift, I've got 9.5" from the top of my tire to my fender flare. An XJ with 6.5" lift has 12.5" from axle center to frame rail, or about 14" from axle center to shock mount. This means you can only get 7" articulation using flush mounts. Stock mounts are dropped 2.5" which brings us to 9.5", which is really only enough to cover our up-travel to bury the wheel, leaving nothing for droop.

So I called a few local shops to ask about drop mounts but no one has any. Everything aftermarket (in Canada) is flush or top mounted, which makes the problem even worse. The guys at the shop argue that I'm wrong and that installing a shock with 6" of travel will somehow give me the same articulation as a shock with 10" travel. I couldn't convince them of how insane they sound.

But, what do you do? I've run flatter leafs in the past, so that I've got enough up-travel to bury my wheel, but then I've only got 2" down travel which is pretty insufficient. Is this just a common problem that most people just deal with, or is there a common solution that I'm not finding? All I can think is flush mount the shocks on the axle, and cut a hole in my floor and mount the top of the shocks to a bar in the cab.

Just installed my D44 which has the shock mounts mounted flush with the axle (no drop). Because of the shackle drop and 6" shackle, my pinion points exactly at the t-case, so the axle is leaned back quite a bit. So now the shock mounts that normally point straight out, are now pointing down the driver side and up on the passenger side.

Drivers side mount is 0.5" below axle center while passenger side is 0.5" above. This only leaves 4" up travel on the drivers and 3" on the passengers, and this ain't sufficient.

This is where I'm getting confused. With 31" rubber, 6.5" lift, I've got 9.5" from the top of my tire to my fender flare. An XJ with 6.5" lift has 12.5" from axle center to frame rail, or about 14" from axle center to shock mount. This means you can only get 7" articulation using flush mounts. Stock mounts are dropped 2.5" which brings us to 9.5", which is really only enough to cover our up-travel to bury the wheel, leaving nothing for droop.

So I called a few local shops to ask about drop mounts but no one has any. Everything aftermarket (in Canada) is flush or top mounted, which makes the problem even worse. The guys at the shop argue that I'm wrong and that installing a shock with 6" of travel will somehow give me the same articulation as a shock with 10" travel. I couldn't convince them of how insane they sound.

But, what do you do? I've run flatter leafs in the past, so that I've got enough up-travel to bury my wheel, but then I've only got 2" down travel which is pretty insufficient. Is this just a common problem that most people just deal with, or is there a common solution that I'm not finding? All I can think is flush mount the shocks on the axle, and cut a hole in my floor and mount the top of the shocks to a bar in the cab.