Whoops. Forgot a hose clamp on the transmission oil outlet. Blew out on the road. Never smelled burning trans fluid before, so at first we thought we'd just driven past an Indian's house. No one else in the truck could quite place the smell either until we noticed the smoke behind us. Some helpful rednecks showed up just as I'd got it fixed, and brought me some trans fluid. Needless to say, I got home and "upgraded" to more hose clamps.

UPGRADEZ!

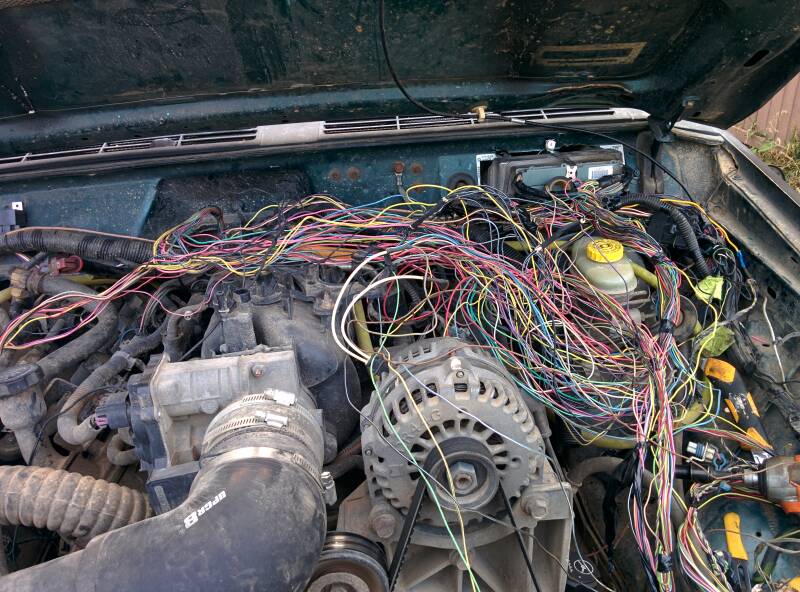

Made some progress under the hood yesterday.

As my upper coolant hose was just a stock xj hose massaged into place, I didn't have room to put the intake to passenger, where it ultimately has to go because I want it routed into the cowl like before (I've already hydrolocked it), and the plan was to stick the ECU in the drivers cowl, thus no room for a 4" intake tube. So last night I decided to get this all done.

Here's the ECU in it's new home.

Fit's like a glove. Probably doesn't even need to be strapped in. Fits snug without binding, doesn't flop around.

Once I get the new cowl intake finished, I'll pull the harness to remove all the stuff I'm not using, and re-work it so the entire harness stays at the back of the engine bay. By the time I'm done, it should look like there's no wiring. I've put this off for too long.

And the new rad hose with the intake flipped over to passenger.

The rad hose was a pain in the ass only because once again, I went to Lordco (useless), and like always, all the guys were busy fawning over the new girl working there (and they're useless even if she's not around). I normally only bother dealing with one guy there (the youngest), as he's the only one who doesn't surprise me that he's managed to survive into adulthood without getting himself eaten by a 3/4 retarded raccoon. He wasn't in, so I tried someone else. I brought some wire sheath formed to the shape I needed, asked the guy if he had anything close, he asks what vehicle it's for, I explain again that it's an XJ, but that it's a chevy 5.3 and completely not Jeep radiator. He, as always, insists he won't have anything that will fit, as is always the response I get from everyone but my one guy. Asked if they have any universal hoses, and he says "nope. No one makes anything like that. It's all OE application.".

Saw another guy there I'd never talked to before (probably the second youngest) and asked him. He says "oh, I'm sure we've got something. Come paruse the wall in the back." Turns out they have 700+ hoses in stock all nicely hung out on the wall. Looked through for a bit, found a few close matches and asked why they don't have any universal hoses. He says "what do you me? who told you that?" and brings me to the entire ****ing WALL of universal hoses and slip adapters. Fuuuuuu. Pointed out that the other guy had said there's no such thing, to which he responds, "was that the short portly guy? Yea, I'm frankly surprised that guy manages to put on his own pants every day.".

Turns out this guy, and the guy I normally deal with, are the manager and assistant manager. Good call Lordco boss. At least you have the right people in charge. Now just give them the authority to fire everyone else.

Seriously, if that was my business, I wouldn't even let most of their employees shop at my store, let alone put them behind the counter.

So, the Universal hose worked perfectly. Grabbed an 18"x1.5" and a 1.5-1.25" slip adapter. Fit perfectly and conformed just right to flip over my intake tube.

I also had to cut out some more of my hood for clearance on the passenger, so I came up with my final design for the scoop, which I'll hopefully have posted tonight.