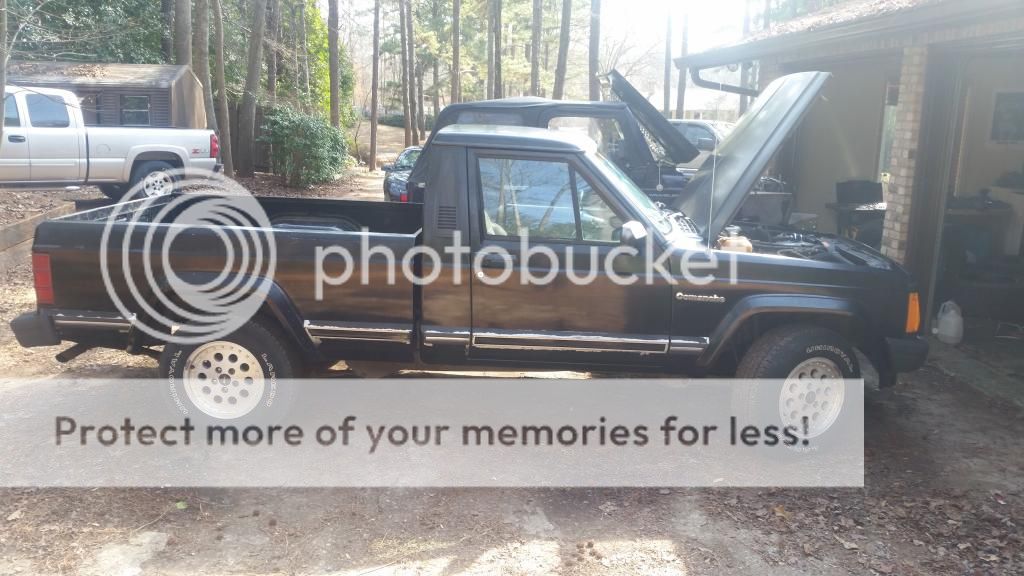

Decided to start a build thread since i picked up a 88 comanche in real good shape.

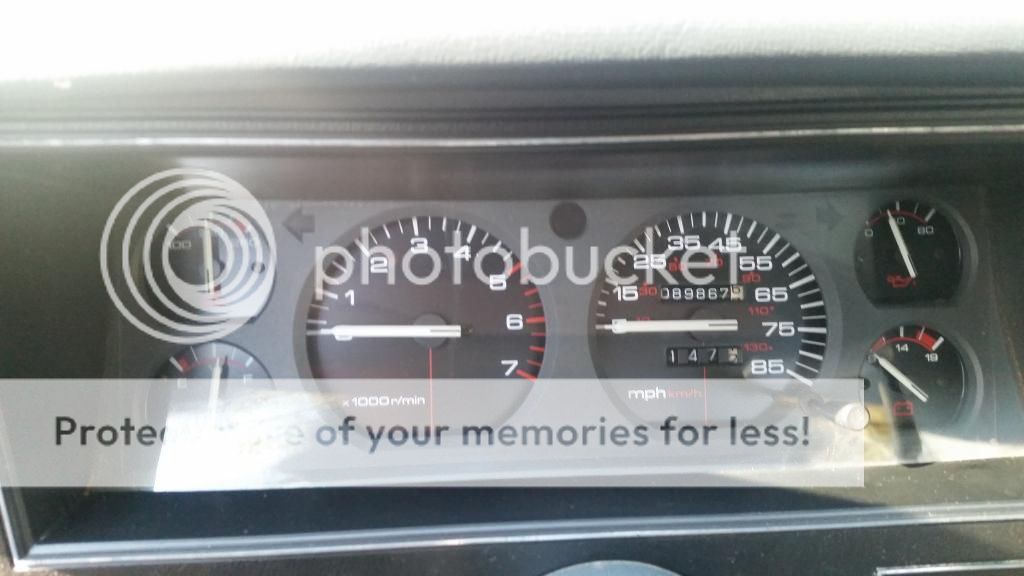

It is a one owner and lived in Georgia its whole life. No rust and 89,xxx miles on the odo.

Its 2wd 5speed but the plan is to covert to 4wd.

Im looking for a 242 transfer case for the fulltime 4x4 feature.

I have a m90 blower off a supercoupe and a bracket to mout inplace of the ac compressor.

The theme I invision is the Jeep version of the GMC Syclone. : AWD, Boost, Black, and Lowered.

Ill swap the new front facia over once i find a black new body cherokee for parts. Im even considering puting a red "comanche" sticker across the top of the windsheild Just like the syclone.

It is a one owner and lived in Georgia its whole life. No rust and 89,xxx miles on the odo.

Its 2wd 5speed but the plan is to covert to 4wd.

Im looking for a 242 transfer case for the fulltime 4x4 feature.

I have a m90 blower off a supercoupe and a bracket to mout inplace of the ac compressor.

The theme I invision is the Jeep version of the GMC Syclone. : AWD, Boost, Black, and Lowered.

Ill swap the new front facia over once i find a black new body cherokee for parts. Im even considering puting a red "comanche" sticker across the top of the windsheild Just like the syclone.