anthrax323

NAXJA Forum User

- Location

- San Antonio, TX

I posted this over on Pirate, and figured I'd repost it here for you guys' enjoyment.

-----

I've been approached to build several roof racks in the last week, and really wanted to be able to bend tube for a specific design I've wanted to build for a very long time (but haven't had an effective means to do so). After reading this thread, I had a Sunday funday project.

I did things a bit differently, and decided to make mine receiver mounted since I don't yet have an anchored bench in the garage, and when I do, it will have 2" receivers built into it.

I made the die from 3/4" x 3/16" flat bar, bent around a small gas cylinder (20 cu ft).

And... The result of the first bend on 14ga 3/4" tube:

Bam. No sidewall deflection. I will be adding a crush bead to the middle of the die to make bending easier, though (getting it started takes some force).

It was a hell of a fun afternoon project, and will make building these roof racks possible. I've since built a 1" die as well:

In my haste, I screwed up 2 aspects of it:

1) The teardrop piece apparently wasn't perfectly flat when I welded the ends together... So it has a slightly off-true arc. After welding the side plates on, this became apparent.

2) I welded the handle receiver tube onto the opposite side of the die. No biggie, just weird.

I did put in a 3/16" inner radius crush bead which yielded a 1/4"+ divot in the tube. I'll be building a replacement 1" die sometime over the next few days (without the crush bead) to see what difference it makes in the process.

Completely forgot to take pics of the resulting bends, but they look good aside from scarring on the tube from the die walls. I'll snap a couple pics tonight.

-----

I've been approached to build several roof racks in the last week, and really wanted to be able to bend tube for a specific design I've wanted to build for a very long time (but haven't had an effective means to do so). After reading this thread, I had a Sunday funday project.

I did things a bit differently, and decided to make mine receiver mounted since I don't yet have an anchored bench in the garage, and when I do, it will have 2" receivers built into it.

I made the die from 3/4" x 3/16" flat bar, bent around a small gas cylinder (20 cu ft).

And... The result of the first bend on 14ga 3/4" tube:

Bam. No sidewall deflection. I will be adding a crush bead to the middle of the die to make bending easier, though (getting it started takes some force).

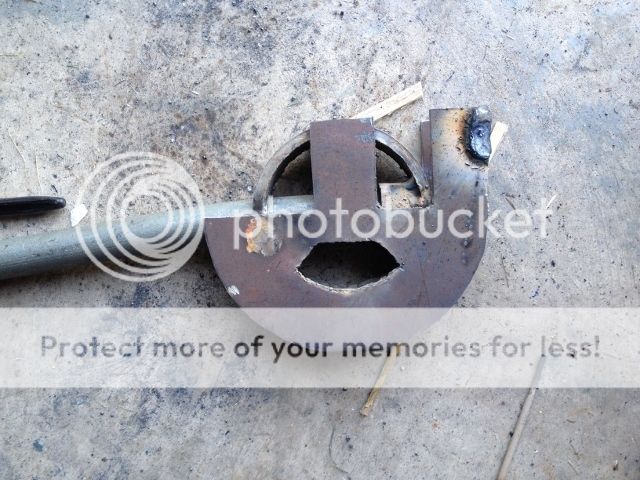

It was a hell of a fun afternoon project, and will make building these roof racks possible. I've since built a 1" die as well:

In my haste, I screwed up 2 aspects of it:

1) The teardrop piece apparently wasn't perfectly flat when I welded the ends together... So it has a slightly off-true arc. After welding the side plates on, this became apparent.

2) I welded the handle receiver tube onto the opposite side of the die. No biggie, just weird.

I did put in a 3/16" inner radius crush bead which yielded a 1/4"+ divot in the tube. I'll be building a replacement 1" die sometime over the next few days (without the crush bead) to see what difference it makes in the process.

Completely forgot to take pics of the resulting bends, but they look good aside from scarring on the tube from the die walls. I'll snap a couple pics tonight.