redrider2911

NAXJA Forum User

- Location

- Yakima, WA

I'VE ALREADY POSTED THIS IN THE JEEPS SHOWCASE BUT THOUGHT THAT THIS MIGHT BE A MORE APPROPRIATE SPOT.

Fabricated everything myself. Whishbone 3-link, bottom long arms, drop t-case x member. 8 in lift on 33's

I measured my passenger tire about 33 in. off the ground. Is that pretty good?

Im going to cut the fenders and maybe throw some bushwackers on so i can fit 35's no problem.

I need longer brake lines then maybe i can get some more flex

I just like this pictures because of the sign in the background

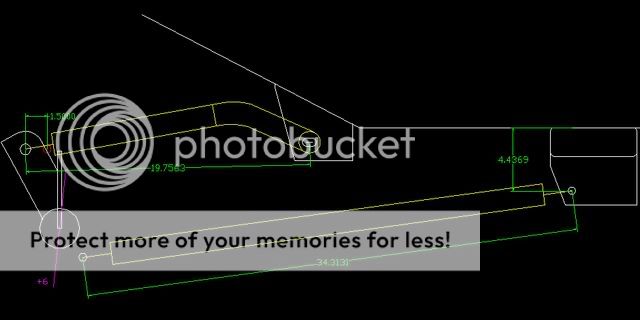

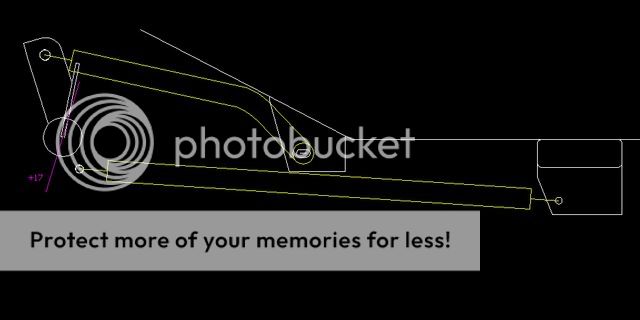

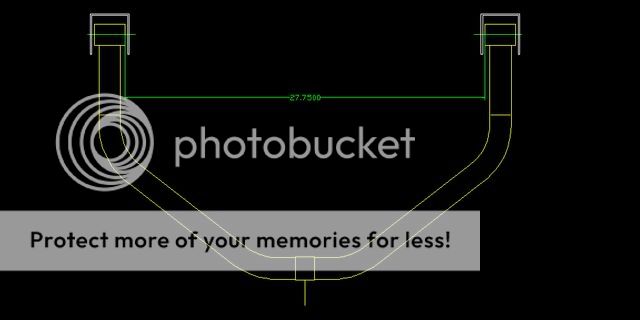

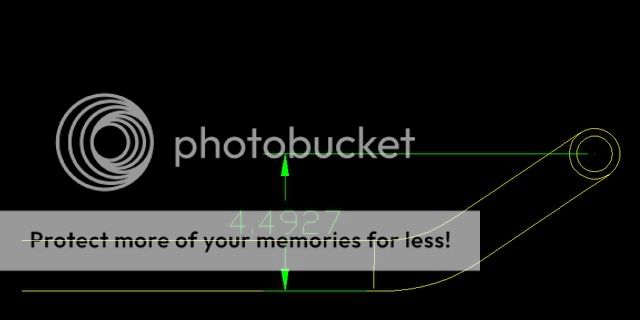

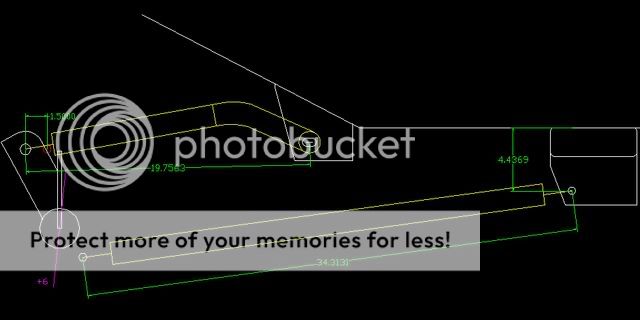

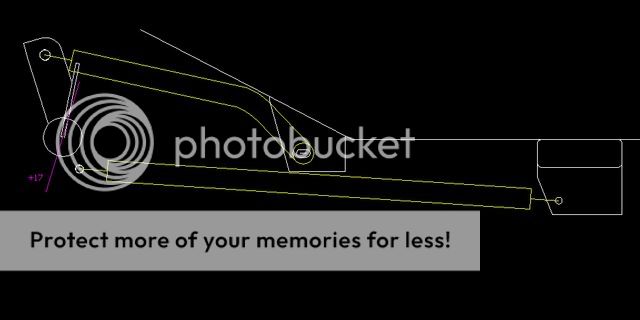

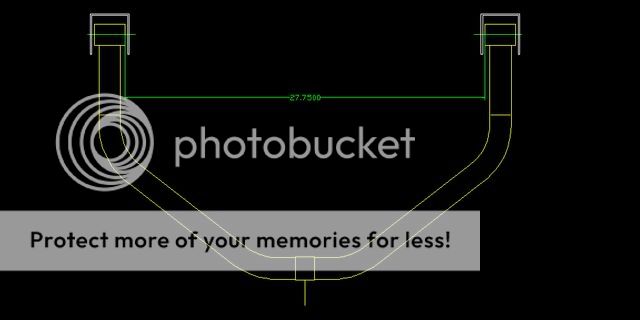

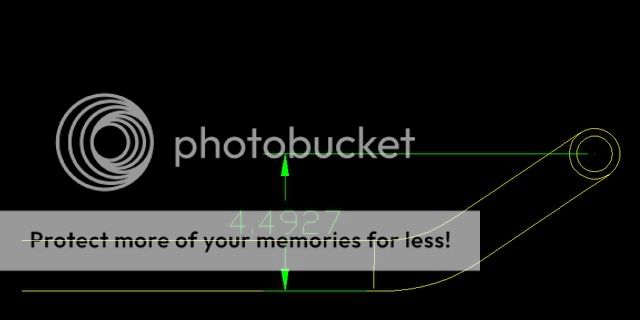

These are the drawings I drew that I went off of for my over all design. Yellow is the 3-link, white is the frame and axle/dif., the purple is the caster angle, and ofcourse the green are just a few dimensions.

A side view at ride height. (8 in. above stock)

Shows the axle flowing through the arc brought up about 7.5 in.

The top view.

The "ears" I had to add to clear the driveline and dif.

Feel free to comment or ask me any questions. I have more drawings but they are rough on peices of paper. I can draft them out if anybody wants anything... for a price. jk

Fabricated everything myself. Whishbone 3-link, bottom long arms, drop t-case x member. 8 in lift on 33's

I measured my passenger tire about 33 in. off the ground. Is that pretty good?

Im going to cut the fenders and maybe throw some bushwackers on so i can fit 35's no problem.

I need longer brake lines then maybe i can get some more flex

I just like this pictures because of the sign in the background

These are the drawings I drew that I went off of for my over all design. Yellow is the 3-link, white is the frame and axle/dif., the purple is the caster angle, and ofcourse the green are just a few dimensions.

A side view at ride height. (8 in. above stock)

Shows the axle flowing through the arc brought up about 7.5 in.

The top view.

The "ears" I had to add to clear the driveline and dif.

Feel free to comment or ask me any questions. I have more drawings but they are rough on peices of paper. I can draft them out if anybody wants anything... for a price. jk