It has nothing to do with the op's ability. A hammer crimp is going to be inferior to a crimp done with a 20 ton press.

I worked on battery-powered industrial equipment for many years.

While I prefered using a big bolt cutter-type crimper, the hammer-type worked fine for field repairs, making hundreds of crimps over the years.

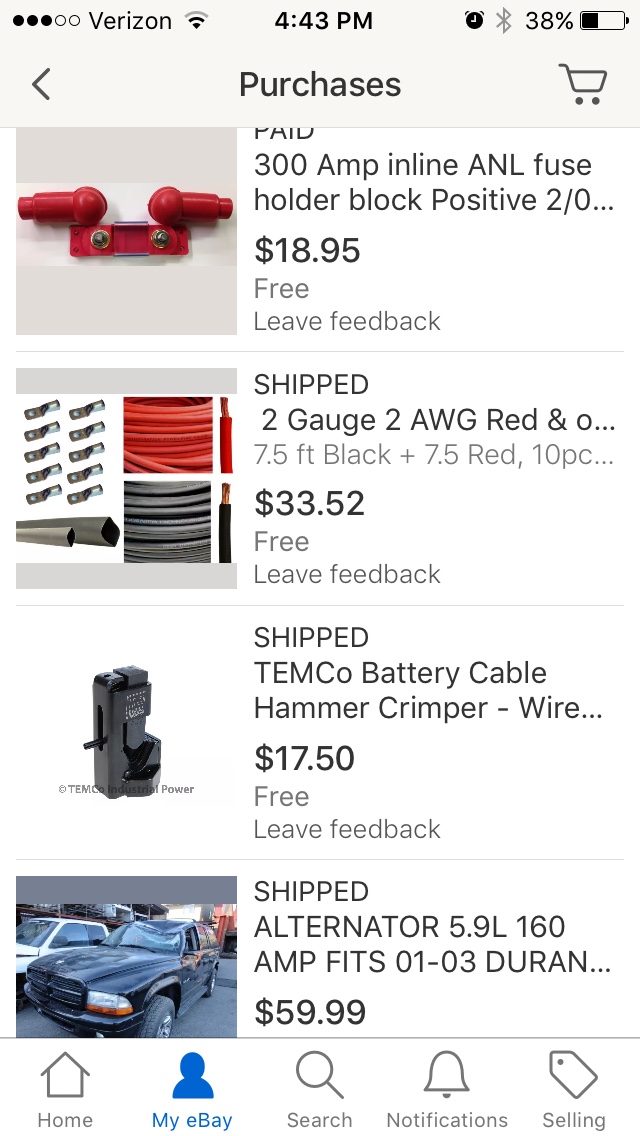

I have both a hammer crimper, bought at West Marine 30 years ago, along with a more recently acquired a HD crimper, bought for use wiring motorhomes and boats.

https://www.delcity.net/store/Heavy!duty-Hammer-Cable-Crimper/p_10383

https://www.amazon.com/FTZ-Correct-...=2025&creative=165953&creativeASIN=B00DZPS1OO

As long as you start with clean cable and lugs, you can make a good connection with hammer crimper, if you pay attention. Make sure to use the right size lugs.

To keep the connections intact, use adhesive-lined shrink tubing.

Much of my Jeep and old motorhome are wired with hammer-crimped connections. None have gone bad in over a decade of use.

That said, the lugs crimped with the FTZ crimper are beautiful compared to any hammer crimp and are what paying customers expect.

If you suspect a crimp isn't good, check for voltage drop over the crimp, when the circuit is under a heavy load. I do this periodically to make sure nothing is going bad.

Once you own a good crimper, it can pay for itself, making up cables for others.