altrocker1

NAXJA Forum User

- Location

- Iowa

Hello all...

Decided to officially kick off this build. a few months ago i started kicking around the idea of building a turbodiesel comanche, but i know the renault motors that came in cherokees and comanches stock were not always the most reliable, nor the most efficient. one day while browsing craigslist, i came across this...

this is an xd2s peugeot 2.3L turbo diesel. similar to hp stock as the renault, but over all a much better motor. they have a pretty standard bosch injection pump and overall they can be tuned a little better than factory to add a little bit more horsepower. the most important part, is that they came stock in some cars with a BA 10-5...and this one came with the stock tranny...score.

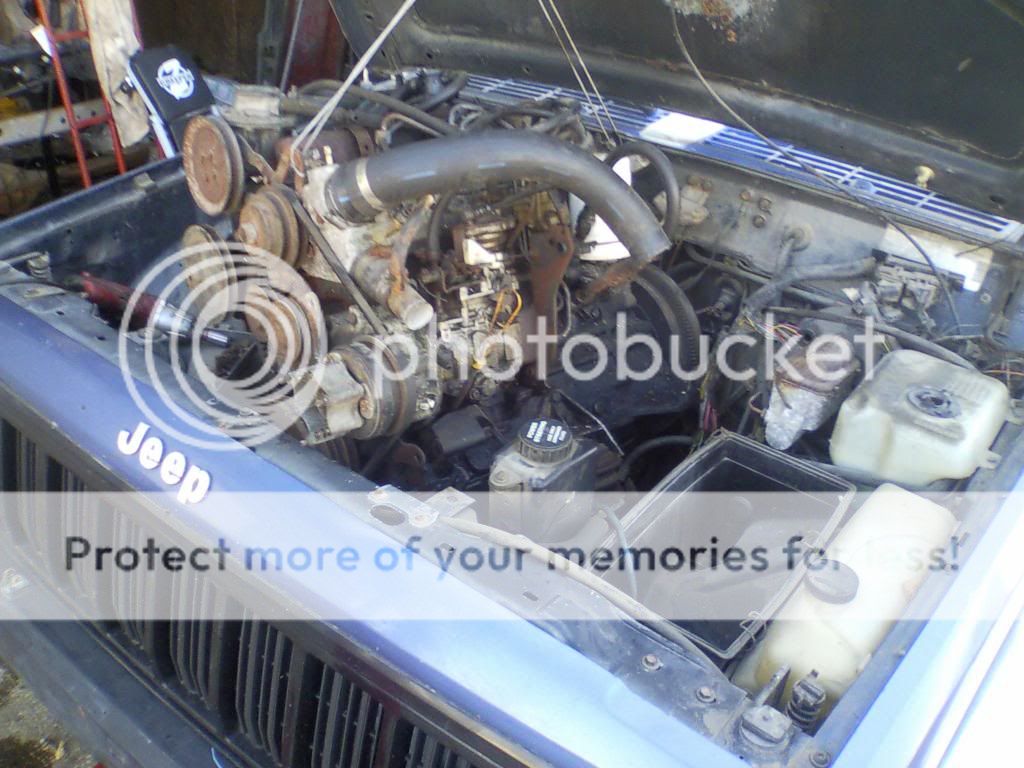

then it came time for a suitable donor...i found a super cheap mj that was a little beat up...i needed new fenders, doors and the roof was crinkled from a rollover...but the pillars were straight, and it had the coveted (NOT!!!) ba 10-5 already in tact. i may be the only guy in the world actually looking for the puke goat, but it will hold up to this little turbo diesel much better than the 4.0.

she wasn't pretty, but would serve my purposes just fine. i have a buddy who even volunteered to fix the roof for me, so all in all it wasn't a bad deal. heck for $250, it was just fine by me.

fast forward a few weeks, when i was attempting to sell the motor in the mj that purchased (i wouldn't be needing it and it ran excellent) i stumbled upon someone who was going to convert a 2.5l 2wd mj into a 4.0 4x4 trail truck...however, he didn't want to spend any more money and he didn't want to beat up the nice mj he had...so i agreed to buy an auto tranny and transfer case for my mj and to do an even swap...so as of tomorrow this gal will be sitting outside of my shop

so it was time to remove what i needed...since his truck is a manual as well, i only needed the necessites...tranny, t case and drive shafts. despite the bitter cold, after a few hours time i had my pot of gold

overall, the tranny is in good shape. it was actually replaced about 2 years ago according to the original owner...and with the ease that it came out with i believe him.

here are the two bellhousings next to each other...jeep on the right and peugeot on the left. the bolt pattern is identical, as i assumed it would be.

the only major difference is the input shaft length...the jeep shaft is 1.25" longer. not terrible, but i will have to put a spacer in between the bellhousing and the tranny. it should be fairly easy to fab one or have it made, and it is just a spacer, not a full on adapter. the slave cylinder on the peugeot is only attached to the bellhousing, so there should be no issues with running a spacer. the spline count, shaft diameter and spline depth is all identical between both transmissions. there is just an extra 1.25" of unsplined shaft on the mj's tranny.

so, my goal is to have this start going together asap...which means starting tomorrow i will be on the hunt for someone to machine me a spacer. i have my brothers father in law ready to go if i need him. he runs a machine shop and would do the machining for next to nothing if i can get the aluminum for him...so let this adventure officially begin!

Decided to officially kick off this build. a few months ago i started kicking around the idea of building a turbodiesel comanche, but i know the renault motors that came in cherokees and comanches stock were not always the most reliable, nor the most efficient. one day while browsing craigslist, i came across this...

this is an xd2s peugeot 2.3L turbo diesel. similar to hp stock as the renault, but over all a much better motor. they have a pretty standard bosch injection pump and overall they can be tuned a little better than factory to add a little bit more horsepower. the most important part, is that they came stock in some cars with a BA 10-5...and this one came with the stock tranny...score.

then it came time for a suitable donor...i found a super cheap mj that was a little beat up...i needed new fenders, doors and the roof was crinkled from a rollover...but the pillars were straight, and it had the coveted (NOT!!!) ba 10-5 already in tact. i may be the only guy in the world actually looking for the puke goat, but it will hold up to this little turbo diesel much better than the 4.0.

she wasn't pretty, but would serve my purposes just fine. i have a buddy who even volunteered to fix the roof for me, so all in all it wasn't a bad deal. heck for $250, it was just fine by me.

fast forward a few weeks, when i was attempting to sell the motor in the mj that purchased (i wouldn't be needing it and it ran excellent) i stumbled upon someone who was going to convert a 2.5l 2wd mj into a 4.0 4x4 trail truck...however, he didn't want to spend any more money and he didn't want to beat up the nice mj he had...so i agreed to buy an auto tranny and transfer case for my mj and to do an even swap...so as of tomorrow this gal will be sitting outside of my shop

so it was time to remove what i needed...since his truck is a manual as well, i only needed the necessites...tranny, t case and drive shafts. despite the bitter cold, after a few hours time i had my pot of gold

overall, the tranny is in good shape. it was actually replaced about 2 years ago according to the original owner...and with the ease that it came out with i believe him.

here are the two bellhousings next to each other...jeep on the right and peugeot on the left. the bolt pattern is identical, as i assumed it would be.

the only major difference is the input shaft length...the jeep shaft is 1.25" longer. not terrible, but i will have to put a spacer in between the bellhousing and the tranny. it should be fairly easy to fab one or have it made, and it is just a spacer, not a full on adapter. the slave cylinder on the peugeot is only attached to the bellhousing, so there should be no issues with running a spacer. the spline count, shaft diameter and spline depth is all identical between both transmissions. there is just an extra 1.25" of unsplined shaft on the mj's tranny.

so, my goal is to have this start going together asap...which means starting tomorrow i will be on the hunt for someone to machine me a spacer. i have my brothers father in law ready to go if i need him. he runs a machine shop and would do the machining for next to nothing if i can get the aluminum for him...so let this adventure officially begin!