TRAILREADYXJ

NAXJA Forum User

- Location

- Raleigh NC

Hey all, been away a while but I’m finally doing some more web wheeling again! Alright,I have chunks of my build in various sections of the forum. I figured it was FINALLY time to gather it all together and post up in the MJ section. This will mostly be a copy and paste from other forums so a lot will be outdated, but I will do some editing….warning…It will be long!

1989 MJ, 4x4, 4.0, AW4, D30/35 , NP231.

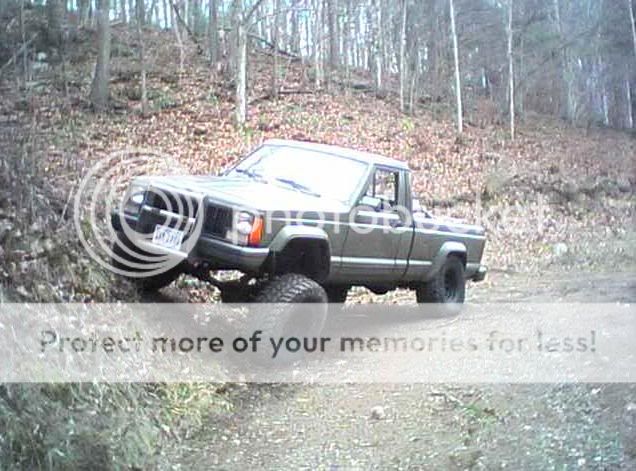

The day I brought it home….back in 2008.

The PO decided to shoot it OD green, but ran out of paint before hitting the roof and in the bed. I was originally going to just flat black it, but the OD grew on me.

I cleaned it up a bit, rattle canned the inside of the bed for now, and primed the roof.

Initially I needed to get this thing on the road ASAP, and as cheap as possible! It needed several things to be road worthy. A couple tires, both unit bearings, and the shocks were totally shot. It also has a rod knock, and had no power with tons of hesitation! The heater didn't work, and the blower would only kick on every once and a while. I can't complain, I didn't expect much from a $500 truck!

I have wanted one of these for years now, and my XJ had seen better days! My plan is to swap the lift, wheels and tires, and engine from the XJ.

So, I got to work! Unfortunately I had to work on it in my gravel/grass driveway due to a friends XJ occupying my small garage.

1989 MJ, 4x4, 4.0, AW4, D30/35 , NP231.

The day I brought it home….back in 2008.

The PO decided to shoot it OD green, but ran out of paint before hitting the roof and in the bed. I was originally going to just flat black it, but the OD grew on me.

I cleaned it up a bit, rattle canned the inside of the bed for now, and primed the roof.

Initially I needed to get this thing on the road ASAP, and as cheap as possible! It needed several things to be road worthy. A couple tires, both unit bearings, and the shocks were totally shot. It also has a rod knock, and had no power with tons of hesitation! The heater didn't work, and the blower would only kick on every once and a while. I can't complain, I didn't expect much from a $500 truck!

I have wanted one of these for years now, and my XJ had seen better days! My plan is to swap the lift, wheels and tires, and engine from the XJ.

So, I got to work! Unfortunately I had to work on it in my gravel/grass driveway due to a friends XJ occupying my small garage.