dgrigorenko

NAXJA Forum User

- Location

- Big Rapids MI

ok gents i'm polishing the turd. before some say its dumb and weak, i already know that. basically what it comes down to is budget, and i have the material already so essentially all this will cost me is time. plus, i am only running 33's, so a strengthened 30 should work out ok.

so here we go:

mocked up some cardboard:

I was originally going to make this out of 2x4x.25 tube, but after mockup figured that i wouldn't be left with a whole lot of material on top of the pumpkin after i cut the bottom off of the tube to weld to the axle tubage. now i am looking at fabbing this thing out of the only other material i have: 10ga sheet. i know that may sound thin at first, but its actually pretty close to 3/16 material.

now for a problem:

after mocking up the cardboard i discovered i have a problem. the driver side UCA mount would be inaccessible in this configuration:

so now to a question: what is a possible solution to this? should i just chop off the control arms and make my own much like the TNT truss? do you guys think that the 10ga would be a strong enough base to attach a UCA arm to? i also have some 1/4 material in smaller pieces that i could use to reinforce the area around the uca possibly.

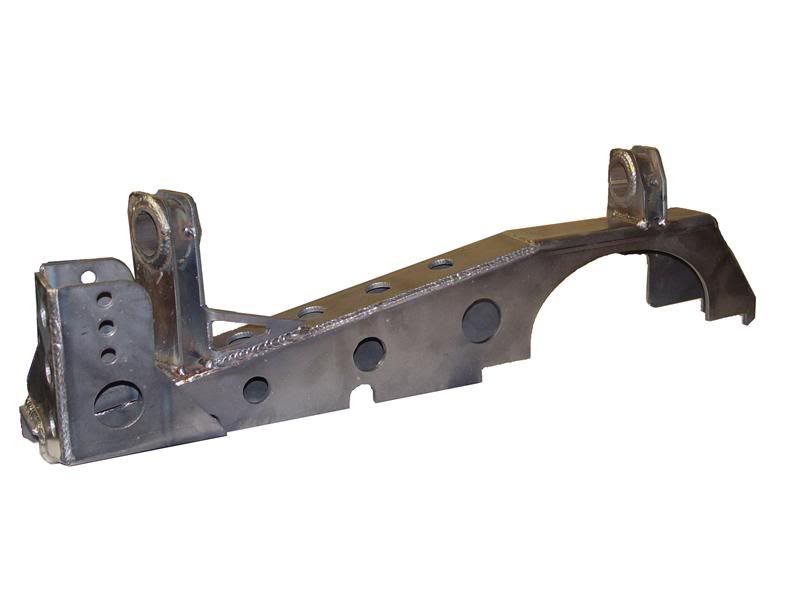

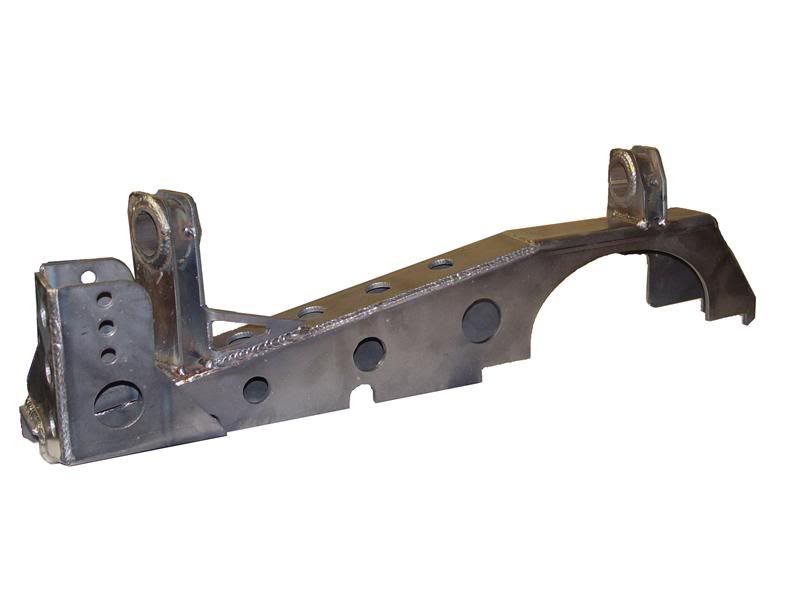

just for reference, here is the TNT truss (Note: obviously their UCA mounts are raised up a few inches has this been problematic at all for anyone?)

so here we go:

mocked up some cardboard:

I was originally going to make this out of 2x4x.25 tube, but after mockup figured that i wouldn't be left with a whole lot of material on top of the pumpkin after i cut the bottom off of the tube to weld to the axle tubage. now i am looking at fabbing this thing out of the only other material i have: 10ga sheet. i know that may sound thin at first, but its actually pretty close to 3/16 material.

now for a problem:

after mocking up the cardboard i discovered i have a problem. the driver side UCA mount would be inaccessible in this configuration:

so now to a question: what is a possible solution to this? should i just chop off the control arms and make my own much like the TNT truss? do you guys think that the 10ga would be a strong enough base to attach a UCA arm to? i also have some 1/4 material in smaller pieces that i could use to reinforce the area around the uca possibly.

just for reference, here is the TNT truss (Note: obviously their UCA mounts are raised up a few inches has this been problematic at all for anyone?)