- Location

- In a strange land

I am going to try to do some trailer mods, and hopefully not end up finding myself building a completely new trailer from scratch.

The starting point is a trailer that I picked up used 5 years ago. It came with a mismatched pair of 3,500 lb axles, only one of which had brakes. But the axles had been converted to spring over, and they ran 6 lug wheels. For me those were good details as that meant better ground clearance & interchangeability with other trailer wheels I already had.

At this point the axles have been swapped for a pair of 5,000 lb (matching) axles, still running 6 lug wheels.

I am now working on strengthening the trailer and setting it up for winching up inoperative vehicles.

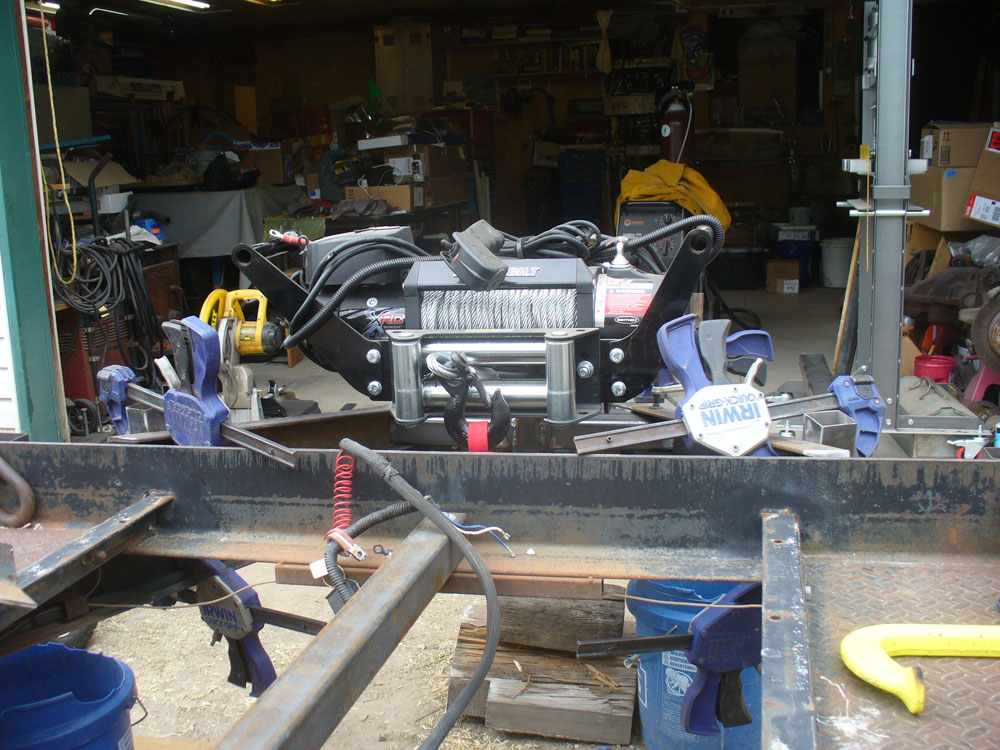

I decided I wanted to run a receiver mount winch. This means the winch is much less likely to get stored on the trailer, out in the elements. It also means the weight of the winch does not need to remain on the trailer tongue. And it means that I don't necessarily even have to have the winch. A second vehicle and a snatch block could also do the job. And the receiver could even serve a completely different function such as support a bike rack. So I worked on collecting pieces and materials accordingly.

Here is the trailer tongue as it sat:

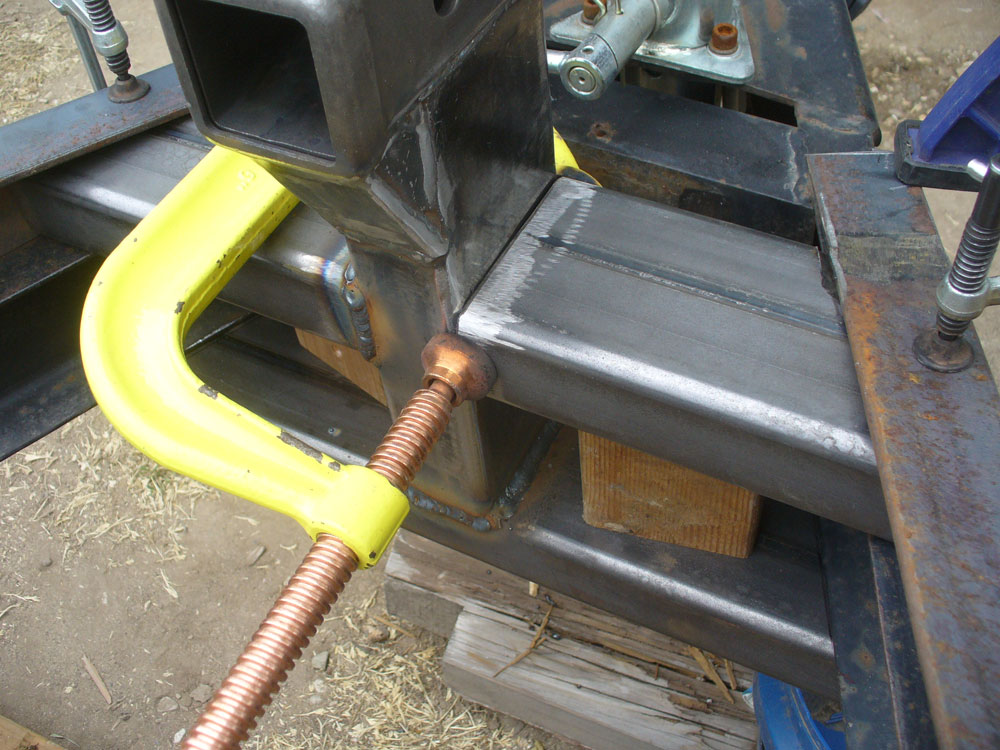

I stripped it down and started my layout. I used 2x4x3/16" rectangular tubing for the receiver mount. I pushed everything as far forward as I could and yet still maintain clearance to swing the jack handle. My knuckles will eventually tell me if I pushed things too far forward. Here I have things in place for the first cuts. The amount of overage on the left side of the pic (right side of the trailer) is by design. That off-cut will become one of my upper supports.

Here is the gist of the idea, with some cardboard aided design:

That cardboard got transferred to a piece of 6" C-channel for an upper frame support gusset.

I totally messed up with my idea for cutting the upper gussets out of a piece of C-channel. In my mind each one is a triangle, and the material is wide enough to flip the pattern and cut the same triangle out of the other side. Well, that is the problem. I get the same triangle. But I need a different triangle because these triangles are 3 dimensional, not 2 dimensional. In hopes that someone else can learn from my mistake, here is what I did (Note the pattern is R/S Up--I added the lettering for the sides after I realized what was the problem):

And moving the pattern over to the other side you can see, I have the same triangle, R/S up:

Now, with the pattern (same piece of cardboard) turned L/S up you can see it will not allow both the R/S and L/S to be cut from the same section of C-Channel:

In order to cut both pieces out of one section of C-channel, it needs to be a long section, like this:

And of course I didn't have another piece of C-channel quite long enough. So, I spliced a piece in order to get to the point of having a pair of gussets:

The starting point is a trailer that I picked up used 5 years ago. It came with a mismatched pair of 3,500 lb axles, only one of which had brakes. But the axles had been converted to spring over, and they ran 6 lug wheels. For me those were good details as that meant better ground clearance & interchangeability with other trailer wheels I already had.

At this point the axles have been swapped for a pair of 5,000 lb (matching) axles, still running 6 lug wheels.

I am now working on strengthening the trailer and setting it up for winching up inoperative vehicles.

I decided I wanted to run a receiver mount winch. This means the winch is much less likely to get stored on the trailer, out in the elements. It also means the weight of the winch does not need to remain on the trailer tongue. And it means that I don't necessarily even have to have the winch. A second vehicle and a snatch block could also do the job. And the receiver could even serve a completely different function such as support a bike rack. So I worked on collecting pieces and materials accordingly.

Here is the trailer tongue as it sat:

I stripped it down and started my layout. I used 2x4x3/16" rectangular tubing for the receiver mount. I pushed everything as far forward as I could and yet still maintain clearance to swing the jack handle. My knuckles will eventually tell me if I pushed things too far forward. Here I have things in place for the first cuts. The amount of overage on the left side of the pic (right side of the trailer) is by design. That off-cut will become one of my upper supports.

Here is the gist of the idea, with some cardboard aided design:

That cardboard got transferred to a piece of 6" C-channel for an upper frame support gusset.

I totally messed up with my idea for cutting the upper gussets out of a piece of C-channel. In my mind each one is a triangle, and the material is wide enough to flip the pattern and cut the same triangle out of the other side. Well, that is the problem. I get the same triangle. But I need a different triangle because these triangles are 3 dimensional, not 2 dimensional. In hopes that someone else can learn from my mistake, here is what I did (Note the pattern is R/S Up--I added the lettering for the sides after I realized what was the problem):

And moving the pattern over to the other side you can see, I have the same triangle, R/S up:

Now, with the pattern (same piece of cardboard) turned L/S up you can see it will not allow both the R/S and L/S to be cut from the same section of C-Channel:

In order to cut both pieces out of one section of C-channel, it needs to be a long section, like this:

And of course I didn't have another piece of C-channel quite long enough. So, I spliced a piece in order to get to the point of having a pair of gussets: