Stallacrew

NAXJA Forum User

- Location

- Cullman, Alabama

Well......we hit a little road block.

We bolted the bellhousing up to the block to see how concentric it was...well it wasnt.

We measured and we are .015'' or so off center. At most we should be .005''. What does this mean? We have to go to the machine shop on a Sunday and bore some holes out. Our approach is going to be:

-Measure total indicator reading (TIR) (which will be 2x how far off center we are)

-Mark the high spot and low spot so we have a line.

-Fasten the bellhousing to the mill's table

-Indicate the holes and bore 1/2 the TIR in the right direction and make .500'' holes

-Turn aluminum or brass bushing on the lathe they have .500'' outside and proper (havet measured yet) ID dimension.

-Press new bushings in and pray.

Moving the holes over is the best solution we've come up with. It'll take some time and this means that I wont be in the Comanche this weekend (but hopefully next)

Anyhow, back to what I posted up for: some pictures of nothing interesting other than what we got done yesterday before we decided to have a family dinner at the Oyster House.

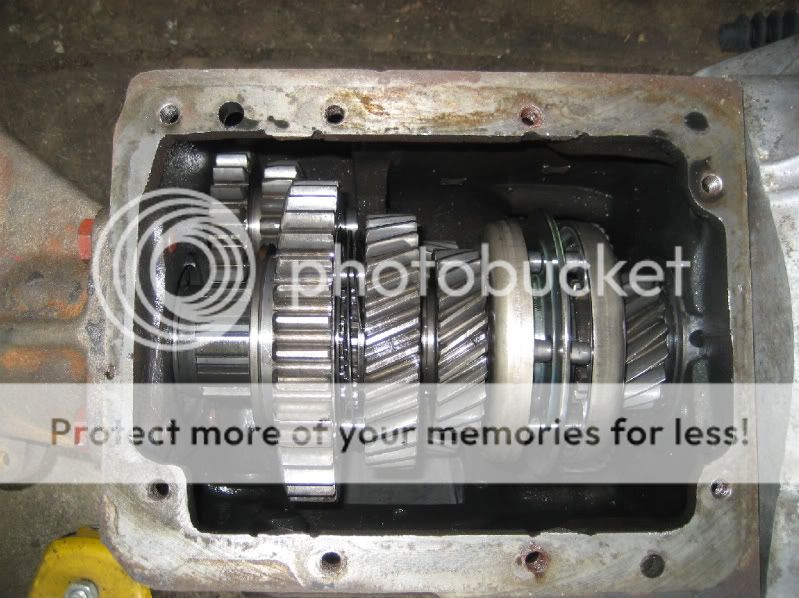

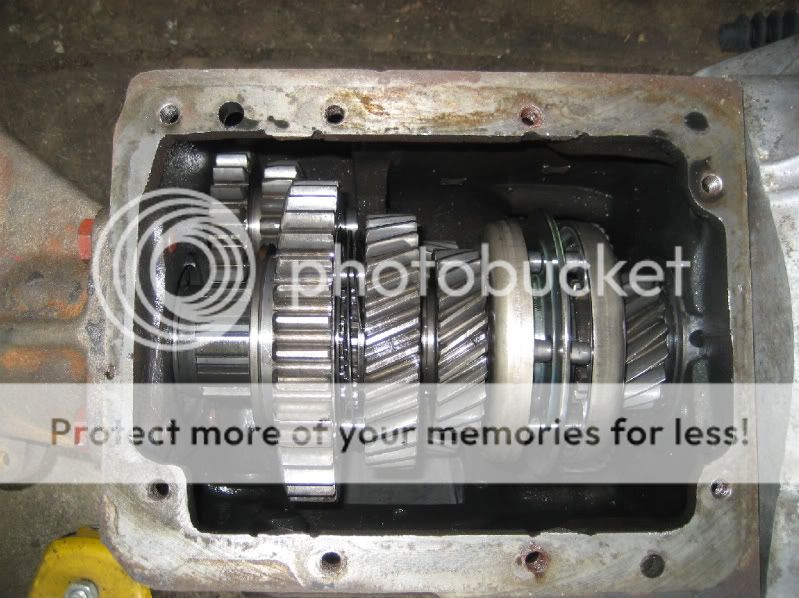

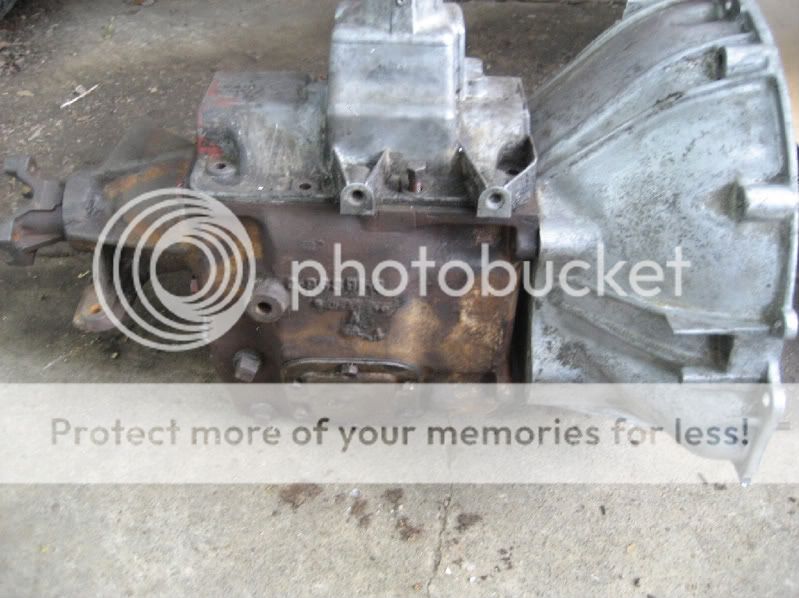

Transmission with the top off:

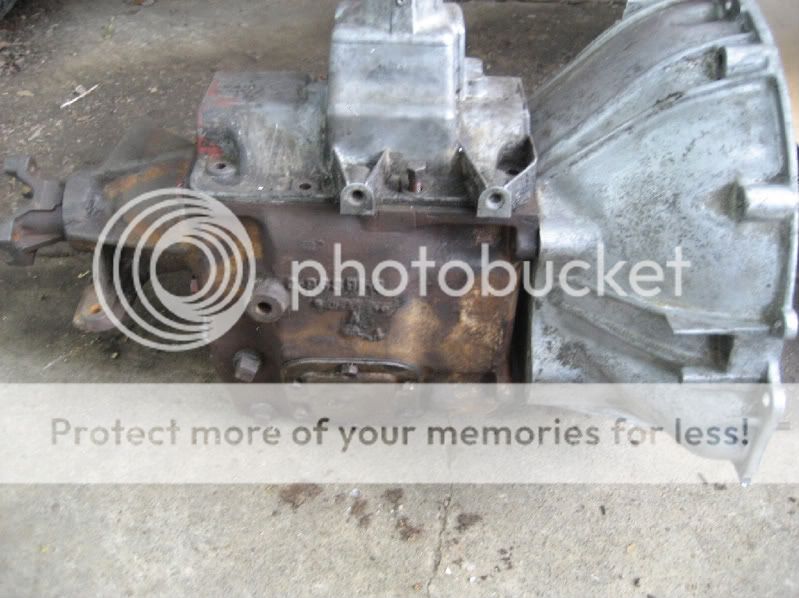

Side view:

Top:

who knows what that means

Strapped to the jack

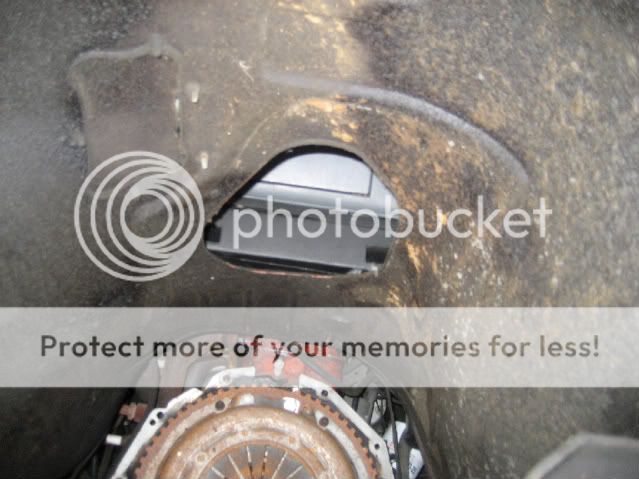

Current situation under there

Engine and trans hole

hole:

I'll take some more pictures when we go to the shop and machine the holes and whatnot. I also lost one of my brass washer/bushings from one of the earlier posts so Ill have to make one more. (maybe 3 or 4).

Unexciting weekend and not the most happy about it.

We bolted the bellhousing up to the block to see how concentric it was...well it wasnt.

We measured and we are .015'' or so off center. At most we should be .005''. What does this mean? We have to go to the machine shop on a Sunday and bore some holes out. Our approach is going to be:

-Measure total indicator reading (TIR) (which will be 2x how far off center we are)

-Mark the high spot and low spot so we have a line.

-Fasten the bellhousing to the mill's table

-Indicate the holes and bore 1/2 the TIR in the right direction and make .500'' holes

-Turn aluminum or brass bushing on the lathe they have .500'' outside and proper (havet measured yet) ID dimension.

-Press new bushings in and pray.

Moving the holes over is the best solution we've come up with. It'll take some time and this means that I wont be in the Comanche this weekend (but hopefully next)

Anyhow, back to what I posted up for: some pictures of nothing interesting other than what we got done yesterday before we decided to have a family dinner at the Oyster House.

Transmission with the top off:

Side view:

Top:

who knows what that means

Strapped to the jack

Current situation under there

Engine and trans hole

hole:

I'll take some more pictures when we go to the shop and machine the holes and whatnot. I also lost one of my brass washer/bushings from one of the earlier posts so Ill have to make one more. (maybe 3 or 4).

Unexciting weekend and not the most happy about it.