-

Welcome to the new NAXJA Forum! If your password does not work, please use "Forgot your password?" link on the log-in page. Please feel free to reach out to [email protected] if we can provide any assistance.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

My 95 2-door stroker project...

- Thread starter wy_jeep

- Start date

stroked88

NAXJA Forum User

- Location

- Carlsbad NM

looks like a cool build so far, this is what im looking at doing hope all turns out well with the cam

Update, I picked everything up from the machinist on Tuesday. We installed the crank tonight, then a rod/piston. The pistons stick out over the deck! We measured the rods and they are stock 4.0L rods, which are too long to use with the 677P pistons. I got screwed over on the kit that I bought :flamemad:. I should have measured the rods before taking them to the machinist. I assumed that they were the right rods since they were BRAND NEW with a STROKER KIT that included 677P PISTONS WHICH USE A 258 ROD.

Thank goodness I still have a set of 258 rods, I'm taking the rods to the machine shop Monday. They'll be shot-peened, resized, and have the pistons installed. I can't blame the kid that I bought it from, it was likely an error with Mile High Jeep. Either way, a $200 error. :-(. On the bright side, I'll have a set of brand new balanced 4.0 rods with the end caps shaved for clearance with a stroker, maybe someone using the KB pistons will pick them up.

I picked up a BBK throttle body to install. I also ordered a Dynomax cat-back, hoping to have a 2.5" downpipe fabbed up this week. We'll be installing the Detroit 8.25 locker, Yukon 29-spline shafts, 4.10 gears, and the RE 3.5" leafs this week as well. Fire-up should be within two weeks!

Comments and questions are certainly welcome. Bumper builds get between 5 and 13 pages of responses. I'm completely rebuilding an XJ and I've had 2 or 3 responses. Lol :dunno:

Thank goodness I still have a set of 258 rods, I'm taking the rods to the machine shop Monday. They'll be shot-peened, resized, and have the pistons installed. I can't blame the kid that I bought it from, it was likely an error with Mile High Jeep. Either way, a $200 error. :-(. On the bright side, I'll have a set of brand new balanced 4.0 rods with the end caps shaved for clearance with a stroker, maybe someone using the KB pistons will pick them up.

I picked up a BBK throttle body to install. I also ordered a Dynomax cat-back, hoping to have a 2.5" downpipe fabbed up this week. We'll be installing the Detroit 8.25 locker, Yukon 29-spline shafts, 4.10 gears, and the RE 3.5" leafs this week as well. Fire-up should be within two weeks!

Comments and questions are certainly welcome. Bumper builds get between 5 and 13 pages of responses. I'm completely rebuilding an XJ and I've had 2 or 3 responses. Lol :dunno:

fireLt.

NAXJA Forum User

- Location

- Craig Colorado

Thats a bummer about the rods! Looks like the project is coming along though. Good Job!

Update. Received the cat-back in the mail and got the rods straightened out. We started assembling the shortblock tonight. All tolerances are within spec and everything is torqued right. We would have assembled more, but we didn't start until about 8:30PM.

I have all of the parts together other than an intake manifold. I've been trying to find one half-effort for about 2 weeks. Now it's crunch time and I really need one! Tomorrow we're going to get started on the head/accessories. I really hope to have this running by the end of March. Stay tuned...

I have all of the parts together other than an intake manifold. I've been trying to find one half-effort for about 2 weeks. Now it's crunch time and I really need one! Tomorrow we're going to get started on the head/accessories. I really hope to have this running by the end of March. Stay tuned...

Frank Z

NAXJA Forum User

- Location

- Colorado Springs

Looking good.

A few suggestions and feel free to disregard if you already know.

Pack the oil pump with Vasoline before you pun the pan on.

Be very liberal with the the Cam break-in Lube.

Add a can of B&G MOA to the oil before you fire it up.

Get a new spring and pin for your cam from your favorite dealer, about $10-12.

I didn't see any reference to a new timing set, reusing the old one?

A few suggestions and feel free to disregard if you already know.

Pack the oil pump with Vasoline before you pun the pan on.

Be very liberal with the the Cam break-in Lube.

Add a can of B&G MOA to the oil before you fire it up.

Get a new spring and pin for your cam from your favorite dealer, about $10-12.

I didn't see any reference to a new timing set, reusing the old one?

Looking good.

A few suggestions and feel free to disregard if you already know.

Pack the oil pump with Vasoline before you pun the pan on.

Be very liberal with the the Cam break-in Lube.

Add a can of B&G MOA to the oil before you fire it up.

Get a new spring and pin for your cam from your favorite dealer, about $10-12.

I didn't see any reference to a new timing set, reusing the old one?

Knew about all but the B&G MOA. I have a new timing kit. The only parts we are reusing are the camshaft, alternator, and powersteering pump. Thanks for the advice!

Frank Z

NAXJA Forum User

- Location

- Colorado Springs

If at all possible, put a new cam in it now. You'll really hate yourself later if you don't.

Frank Z

NAXJA Forum User

- Location

- Colorado Springs

Yep, a bit more lift and duration.

Well, I did want to run the upgraded cam. Problem was that I had a budget. It would have cost me about $350 more to run the 232-4 cam. Instead, I sold the cam and used the money to buy an APN header, upgraded downpipe, and BBK throttle body. Those 3 combined probably won't add the power the cam would have added, but it's the excuse I used :-(. I'm already like $2000 over budget. Lol.

Frank Z

NAXJA Forum User

- Location

- Colorado Springs

You get a Comp or Crower from Summit for less than $150.00

I already had the Comp 232-4. I didn't want to run it with stock valvesprings since the pressure isn't what comp recommended. Not that I'd have the RPMs high enough to worry about valve float...more about peace of mind. I say it would've cost $350 because of the cam cost and the Mopar valve springs/retainers (about $200'ish). Instead I sold the cam for $115 and used the money towards the other mods. I would have cheated the camshaft by not running an upgrade manifold/exhaust/throttle body with it.

Without a doubt, the camshaft would have added a good chunk of horsepower/torque. I decided to keep the stock cam since I was already way over budget with upgrading to the 29-spline Yukon axles/detroit locker. The rod hiccup didn't help either. Some probably think I'm an idiot for not spending the extra money to run the cam. The thing is...this project was completely off of impulse and unnecessary, saving the $350 helps me sleep better at night. Well worth the absence of the cam

Without a doubt, the camshaft would have added a good chunk of horsepower/torque. I decided to keep the stock cam since I was already way over budget with upgrading to the 29-spline Yukon axles/detroit locker. The rod hiccup didn't help either. Some probably think I'm an idiot for not spending the extra money to run the cam. The thing is...this project was completely off of impulse and unnecessary, saving the $350 helps me sleep better at night. Well worth the absence of the cam

YELLAHEEP

NAXJA Forum User

- Location

- Littleton, Colorado

Some probably think I'm an idiot for not spending the extra money to run the cam. The thing is...this project was completely off of impulse and unnecessary, saving the $350 helps me sleep better at night. Well worth the absence of the cam

Not me. After seeing the issues Chris (xj-grin) has been facing with his stroker rebuild and all the cam/lifter/push rod drama he's gone through, and now having exhausted his abililty to try to fix his problem getting it to run without noise....... I don't blame you one bit.

Although, I'll be curious to see if that engine becomes a bit of a gas hog, having the larger bore/stroke without having better air intake/exhaust flow...... :dunno:

Keeping my fingers crossed for you in hopes you have a nice, smooth start up when the time comes! :thumbup:

Last edited:

Thanks for the support Yella. If I get 14-15MPG I'll be happy. 4.10 gears and a 5-speed, maybe I'll get lucky  . Last night I pulled all of the carpet/seats out. The interior is trashed so I'm hoping to somewhat restore the carpet. We also managed to pull the rear axle out. Pics:

. Last night I pulled all of the carpet/seats out. The interior is trashed so I'm hoping to somewhat restore the carpet. We also managed to pull the rear axle out. Pics:

Last edited:

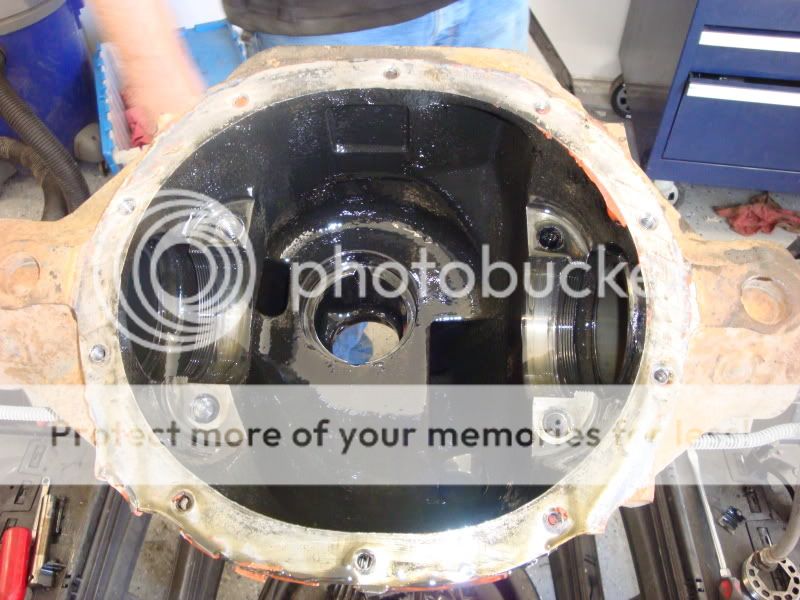

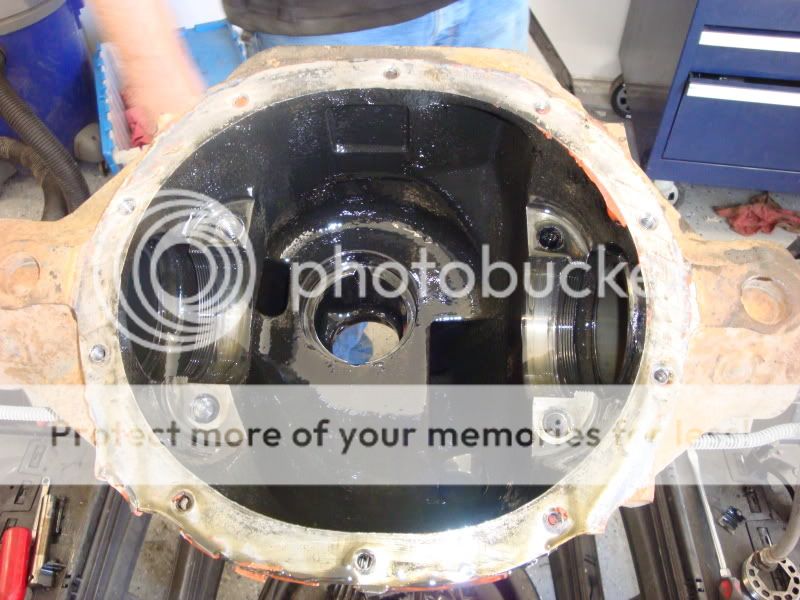

Today we started working on the rear axle. Got the Detroit locker with 4.10's and the Yukon 29-spline axles in. Also replaced axle bearings and seals. Removed the stock exhaust. Such a pain with everything rusted, but we got it out. Snapped a comparison pic of the Dynomax cat-back to the stock one.

Tinted the rear tail lights a la VHT Niteshades. One of the leaf spring bolts is rust welded to the bushing. We have to cut it out. No big deal. If all goes well she'll be started by the end of this week :yelclap:

Tinted the rear tail lights a la VHT Niteshades. One of the leaf spring bolts is rust welded to the bushing. We have to cut it out. No big deal. If all goes well she'll be started by the end of this week :yelclap:

Kiefer316

NAXJA Forum User

- Location

- Littleton, Crawloardo

Cant wait to tear a turdy apart to regear.

But im going with an 8.8 and d30... with 33's right off the bat.

Oh ya btw. lookin good. hurry up and get that junk done

But im going with an 8.8 and d30... with 33's right off the bat.

Oh ya btw. lookin good. hurry up and get that junk done

Update. We ran into a couple speedbumps. The the driver's side leaf spring bolt was siezed and we broke off the weldnut inside while trying to get it out. We had to could a small square into the unibody to get the bolt out and fished through another one. Rear axle is in along with the RE 1463 leafs and trailmaster shocks.

Lol...Even with the motor out the rear still sits higher than the front. Looks like I might be adding some spacers to the front. How do the leafs break in? When I searched some say they stayed the same for 2 years, others say they settle to 4" within 6 months.

Also got the Tomken rear bumper installed. I only had the driver's side nutstrip. Thankfully, Rod over at TNT customs donated a bracket that he was using to make a bumper with. The bracket had the nuts welded in place, just had to be trimmed to fit. Works great!

The longblock is complete, we need to bolt the APN header and 99 intake up to it along with the accessories. She should be fired up this week!

Oh yeah, I still need to get the injectors figured out. Not sure if I want to run 24lb/hr ford injectors or a map adjuster. Air is thin up here so I don't know if it will even run lean on stock injectors.

Pics...

Lol...Even with the motor out the rear still sits higher than the front. Looks like I might be adding some spacers to the front. How do the leafs break in? When I searched some say they stayed the same for 2 years, others say they settle to 4" within 6 months.

Also got the Tomken rear bumper installed. I only had the driver's side nutstrip. Thankfully, Rod over at TNT customs donated a bracket that he was using to make a bumper with. The bracket had the nuts welded in place, just had to be trimmed to fit. Works great!

The longblock is complete, we need to bolt the APN header and 99 intake up to it along with the accessories. She should be fired up this week!

Oh yeah, I still need to get the injectors figured out. Not sure if I want to run 24lb/hr ford injectors or a map adjuster. Air is thin up here so I don't know if it will even run lean on stock injectors.

Pics...

xj-grin

NAXJA Member #1096

- Location

- Colorado Springs, Colorado

my gut reaction is you want the Ford 24lb injectors, as that is what virtually all of us with strokers run, some with an adjustable MAP on top, some not -- that said, you're the only guy I know building a stroker with a stock cam in place... your fuel requirements might not be as great as those of use with bigger cams.

Similar threads

- Replies

- 8

- Views

- 1K

- Replies

- 2

- Views

- 2K

- Replies

- 3

- Views

- 673