Last year I came across a deal on a pair of axles with 4.11 gears at a price that was too good to pass up. The problem was, they came out of an MJ rather than an XJ so I had to weld on some new spring perches and shock mounts. The MJ perch is on the bottom of the axle tube as MJ’s are spring under rather than spring over like the XJ. The shock mount on the MJ is part of the u-bolt plate that sandwiches the leaf springs and clamps them to the axle.

This was a perfect time to put pencil to paper and redesign the factory shock mount bracket. I had two goals in mind. First was improving clearance. The factory mount on the XJ hangs down about 4” or more below the bottom of the axle tube. The other goal was to raise the mount in order to use my existing shocks with more lift. I run Rusty’s hydro shock which is sold with his 3” lift kit. I thought that by raising the mount, I would be able to use these shocks for a 4” to 5” lift.

Actually, I had three goals: the third being to spend as little money as possible on this project. After all, that’s why I was swapping in these axles in the first place. I’m too cheap to buy new gears and pay someone to install them. I do all kinds of automotive work, but for some reason, have always shied away from setting up ring and pinions.

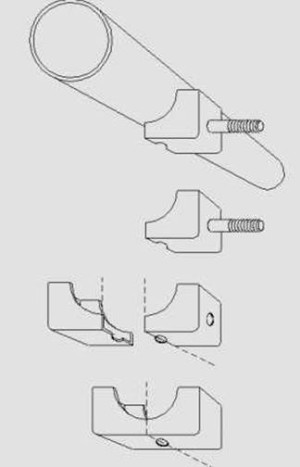

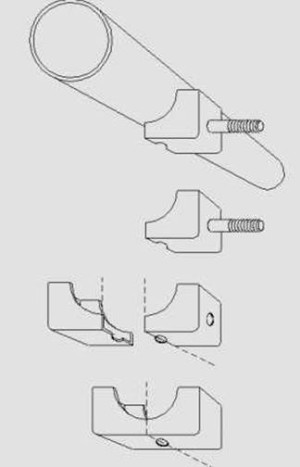

I started by buying some extra spring perches. Not like the ones I used for the leaf springs, these were some cheap ones used for trailer axles. I think they were about $ 1.95 each, a little smaller and narrower than the regular ones but still made out of heavy gage ¼” thick steel. Similar ones should be available at any local trailer supply store or farm store like Tractor Supply.

You start by cutting the perch in half, right across where the hole for the center pin goes. Only one perch is needed to make both shock mount brackets. Drill a 5/8” hole through each bracket as pictured and then slide the bolt through the hole. Weld the hex head of the bolt to the inner side of the bracket.

At this point, about the only thing left to do is to weld the bracket to the axle tube. As with the factory setup, weld the driver’s side bracket on the rear of the tube and the passenger side bracket to the front. This helps to control axle wrap or hop. Although I didn’t do it, it would be a good idea to bevel the sharp corners on the bottom corners of the brackets at 45° with a 4” grinder. Follow up with your choice of painting methods to keep the rust away.

I slipped about 4 of the 5/8” flat washers on the bolt before sliding on the shock. This helps to space the shock body away from the axle tube. As an alternate method, the two short sections of steel tubing could be used to accomplish the same thing followed by one flat washer to retain the rubber shock bushing. Then put another flat washer on after the shock and finally the locking nut.

This project is relatively quick and easy, plus it accomplished two of my original goals. It’s cheap and gained me about 3 or more inches of clearance under the axle.

In conjunction with this project, I raised my Jeep another inch on top of Rusty’s 3” lift. After a short bit of driving, I found that Rusty’s hydro shocks bottomed out on some moderate dips so I ended up replacing them with a shorter Monroe SensaTrack shock. Maybe when I go up another inch or two, I can put them back on.

By Alyn Loya, aka MaXJohnson

This was a perfect time to put pencil to paper and redesign the factory shock mount bracket. I had two goals in mind. First was improving clearance. The factory mount on the XJ hangs down about 4” or more below the bottom of the axle tube. The other goal was to raise the mount in order to use my existing shocks with more lift. I run Rusty’s hydro shock which is sold with his 3” lift kit. I thought that by raising the mount, I would be able to use these shocks for a 4” to 5” lift.

Actually, I had three goals: the third being to spend as little money as possible on this project. After all, that’s why I was swapping in these axles in the first place. I’m too cheap to buy new gears and pay someone to install them. I do all kinds of automotive work, but for some reason, have always shied away from setting up ring and pinions.

I started by buying some extra spring perches. Not like the ones I used for the leaf springs, these were some cheap ones used for trailer axles. I think they were about $ 1.95 each, a little smaller and narrower than the regular ones but still made out of heavy gage ¼” thick steel. Similar ones should be available at any local trailer supply store or farm store like Tractor Supply.

You start by cutting the perch in half, right across where the hole for the center pin goes. Only one perch is needed to make both shock mount brackets. Drill a 5/8” hole through each bracket as pictured and then slide the bolt through the hole. Weld the hex head of the bolt to the inner side of the bracket.

At this point, about the only thing left to do is to weld the bracket to the axle tube. As with the factory setup, weld the driver’s side bracket on the rear of the tube and the passenger side bracket to the front. This helps to control axle wrap or hop. Although I didn’t do it, it would be a good idea to bevel the sharp corners on the bottom corners of the brackets at 45° with a 4” grinder. Follow up with your choice of painting methods to keep the rust away.

I slipped about 4 of the 5/8” flat washers on the bolt before sliding on the shock. This helps to space the shock body away from the axle tube. As an alternate method, the two short sections of steel tubing could be used to accomplish the same thing followed by one flat washer to retain the rubber shock bushing. Then put another flat washer on after the shock and finally the locking nut.

This project is relatively quick and easy, plus it accomplished two of my original goals. It’s cheap and gained me about 3 or more inches of clearance under the axle.

In conjunction with this project, I raised my Jeep another inch on top of Rusty’s 3” lift. After a short bit of driving, I found that Rusty’s hydro shocks bottomed out on some moderate dips so I ended up replacing them with a shorter Monroe SensaTrack shock. Maybe when I go up another inch or two, I can put them back on.

| Parts List: 1 - leaf spring perch for 2 ½” to 2 ¾” axle tube 2 - 4” long 5/8 fine thread, grade 5 bolts 2 - 5/8 fine lock nuts. 4 - or more 5/8 ID flat washers miscellaneous welding supplies Optional:W 2 - 5/8” ID steel tube ½” long |

By Alyn Loya, aka MaXJohnson