Blue XJ

NAXJA Forum User

- Location

- Sterling Heights, Michigan

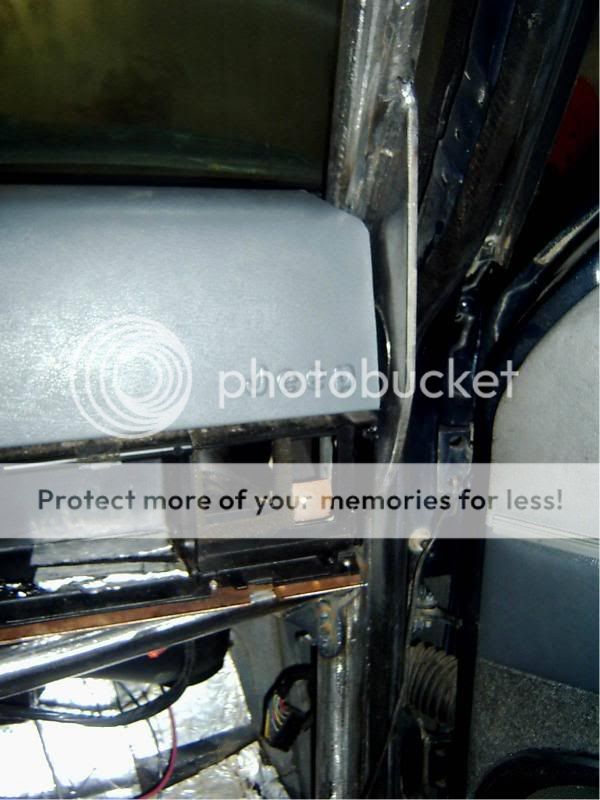

I'ev searched for this but didn't really find what I am looking for. I am wondering if anybody has put a cage in a early body style XJ that goes throug the dash like many TJ cages do. I wan't it to hug the firewall, so I don't loose much space inside since I have long legs.

Has anyone done this? And if so, how much needs to be removed/relocated to fit the tubing? And anyone have pics?

edit:

Like this one, just on the early style dash.

http://jcroffroad.com/images/Butler/13.jpg

Has anyone done this? And if so, how much needs to be removed/relocated to fit the tubing? And anyone have pics?

edit:

Like this one, just on the early style dash.

http://jcroffroad.com/images/Butler/13.jpg

Last edited: