Well, I was going to go to Bonneville with some buddies and take the Jeep out onto the salt. This got me thinking about rust - which led to a dizzying volume of paint and rubber undercoating being shot at the Jeep.

Then I wanted some arm rests that didn't suck, so I took the door panels apart and had an upholstery shop build them up with padding. Much comfier and better looking than the hard plastic junk.

And finally, when Speed Week was cancelled because of rain, I said "Damned if I'm not having some automotive fun this week..." and finished the WJ swap I've been putting off.

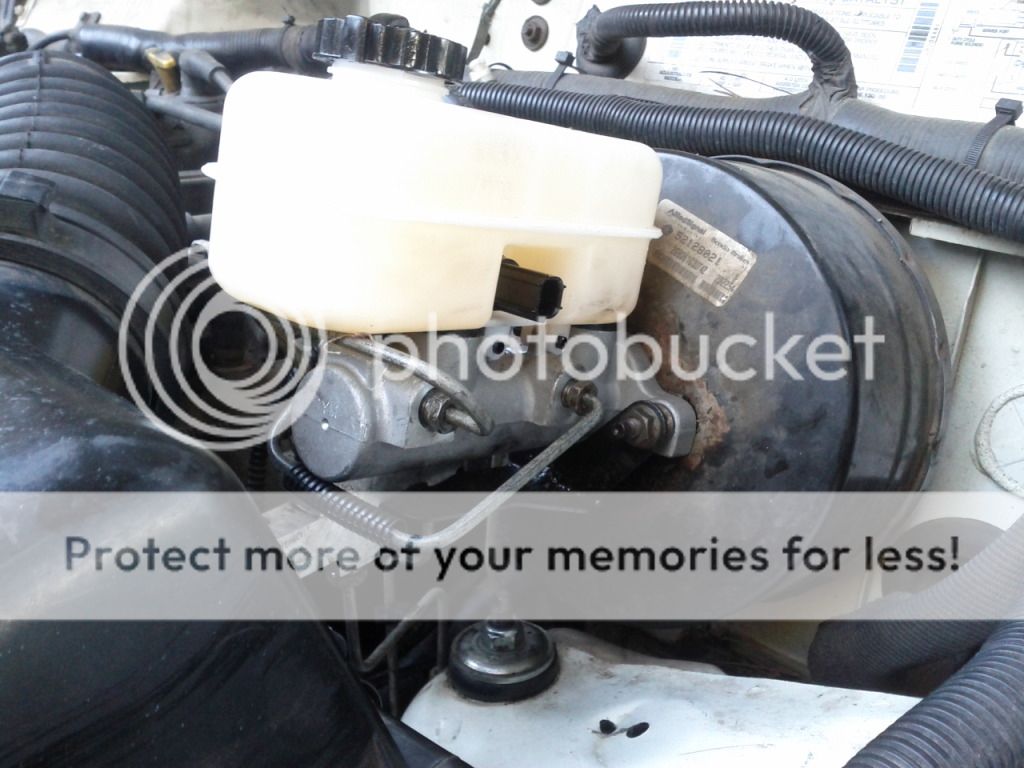

That right there is the motivation. Another 1" of rotor diameter & twin-pot calipers. Another great advantage - the pad support is distinct from the knuckle and uses shims / clips to isolate and quiet the pad. XJ stuff just seems cheap in comparison. Hell, it *is* cheap.

Here's the result:

That's the WJ knuckle, Akebono caliper / pads, 01 Ford Explorer Sport-Track front rotor, '00 XJ hub & 1.5" wheel spacer so my factory 15" steelies will fit. Not pictured are the 9/16" grade 8 washers in between the rotor & hub, needed to space the rotor correctly.

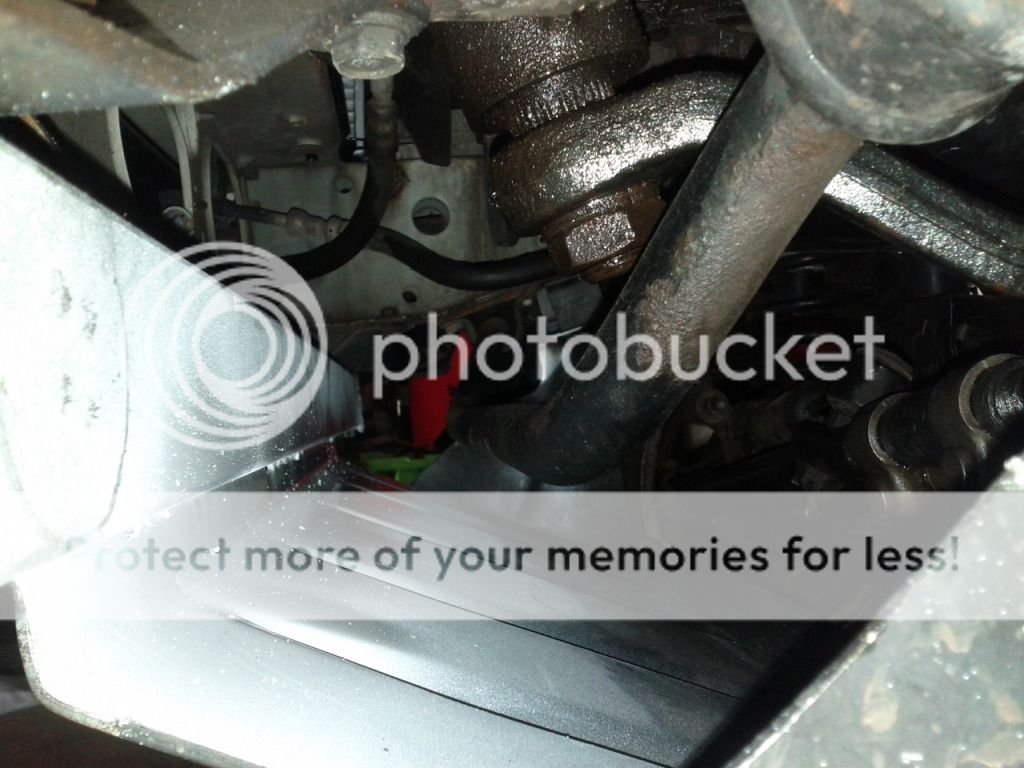

This is a shot of the clearance between the factory sway brackets / coil bucket & the passenger's side upper steering arm. It's no problem for me, I'm using stock linkage, but I include the picture so people can see what's what. If you want to go crossover with Chevy stuff or Heims, you *must* chop the sway bracket & probably clearance the coil bucket. I said "no thanks" to that as well as the OTA track bar.

The lower pass. steering arm is 3/4" lower than the steering arm on an XJ knuckle. This means the drag link's angle changes but track bar angle doesn't. This equals bump steer. Here's my solution...

ZJ pitman arm. 3/4" drop. On my test drive, I couldn't feel *anything* different about my steering with the WJ knuckles, stock linkage / TB & ZJ arm. Happy as could be.

The results, with Centric OEM replacement rotors / pads, are fantastic. Pedal modulation is present, though I will have to recalibrate my foot a little bit. When I apply pressure like I mean to stop, I STOP. Emphatically. Better brakes than all but the 2 Corvettes I've driven. Very, very worth the time / money. And at $25 for a ZJ pitman arm, anyone who's front end needs a refresh can go WJ brakes for very little extra money. It's awesome.