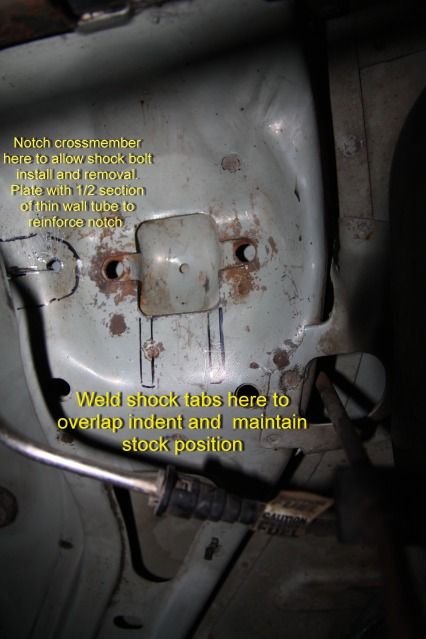

When I build my D44, I moved the axle shock mounts up flush with the bottom of the axle tube to protect the shock from rock bashing. This required me to stick with an 8" travel shock, due to the reduction on overall length from mount to mount.

When shopping for new shocks, I decided that I wanted the have a bit more travel in the rear and punching through the floor was not an option for me, so I pondered the relocation of my lower mounts.

While following a JK Wrangler down the road, the placement of their lower shock mounts caught my eye. They hang fairly low, but they are placed further outboard than the stock XJ shock position, which reduces the potential for them to get smacked by a large rock that could damage the shock eye.

I decided to fab up a lower shock mount that would move the mounting point nearer to the tire, and lower than the axle tube, to net 2" of additional shock travel. This would also allow me to keep the shock mounting position at a reasonable angle so as to not effect the performance of the shock.

I started with this Ruffstuff axle tube shock mount.

(more on using PVC pipe to mock up your shock mount locations later....pretty slick trick)

I then notched a piece of 2" x 3" x .188 wall rectangle tube to fit the axle tube and allow access for the spring U-bolts and them mated the shock mounts to the tube.

With the mounts fabbed, I used my PVC mock shock to set the correct position for the mount and then I burned them on to the axle tube, then primed and finished them.

Completed shots of lower shock mount.

These mounts are positioned further outboard and higher than the stock position, so time will tell if this mount will attract rocks or not.