Incredible Hulk

NAXJA Forum User

- Location

- Burnsville, Minnesota

A few of you guys asked me to post pics of what I ended up doing on my rear bumper for its mount. Well, here it is.

Should be done before the end of the weekend. Whats good about building these thigns is it is giving me some great seat time behind my welder. I think Im slowly getting better.

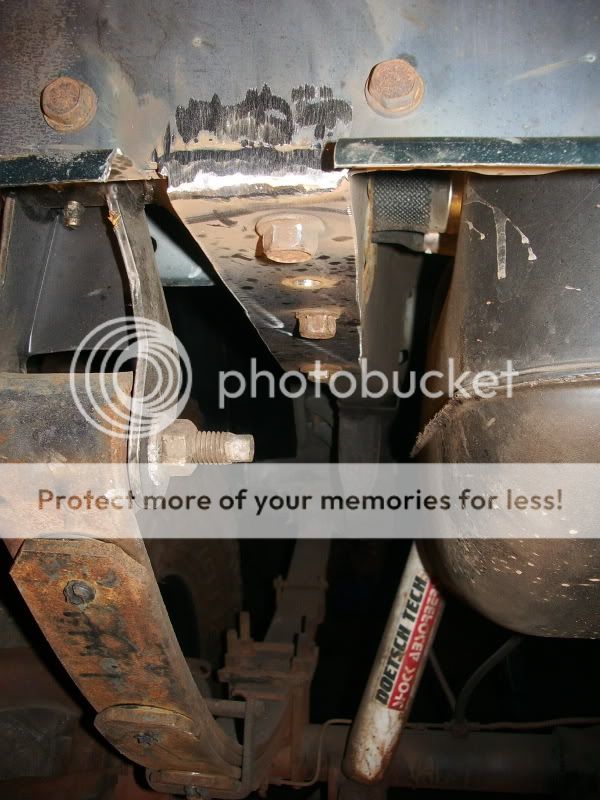

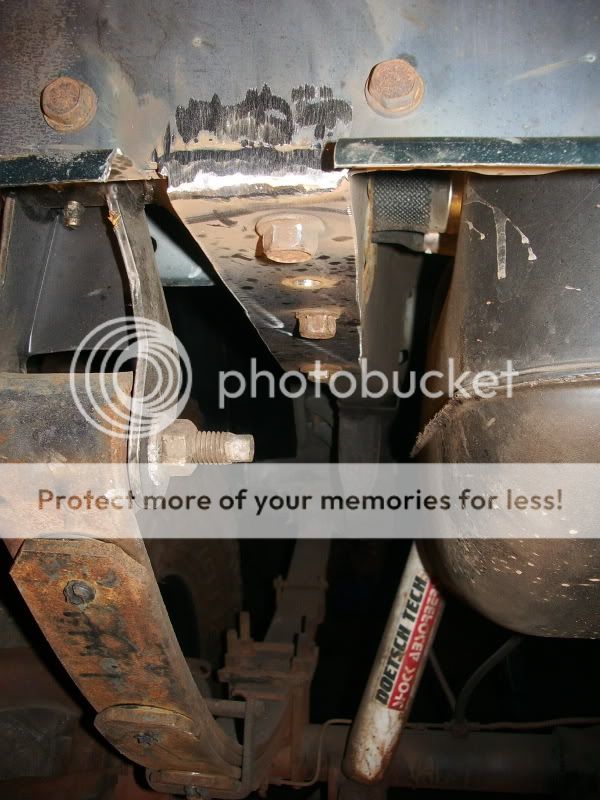

Here's the mounting bracket. I cut off the box section on the unibody, and then rewelded the corners back together. The new bracket includes all 8 of the stock bumper bolts, also wraps around the corner to include the rear leaf spring bolt, and wraps under to include all the bottom tow hitch bolts as well. There are also two bolts right in the middle now since it was warping out a little.

Heres where the bumper itself is at now. The D ring tabs go all the way through, and they are also welded to the tabs that will mount to the bracket on the jeep itself. It will also have wrap arounds on the ends to protect the upper quarters. That will be done tomorrow.

I'll throw up pics of it all done soon.

Should be done before the end of the weekend. Whats good about building these thigns is it is giving me some great seat time behind my welder. I think Im slowly getting better.

Here's the mounting bracket. I cut off the box section on the unibody, and then rewelded the corners back together. The new bracket includes all 8 of the stock bumper bolts, also wraps around the corner to include the rear leaf spring bolt, and wraps under to include all the bottom tow hitch bolts as well. There are also two bolts right in the middle now since it was warping out a little.

Heres where the bumper itself is at now. The D ring tabs go all the way through, and they are also welded to the tabs that will mount to the bracket on the jeep itself. It will also have wrap arounds on the ends to protect the upper quarters. That will be done tomorrow.

I'll throw up pics of it all done soon.