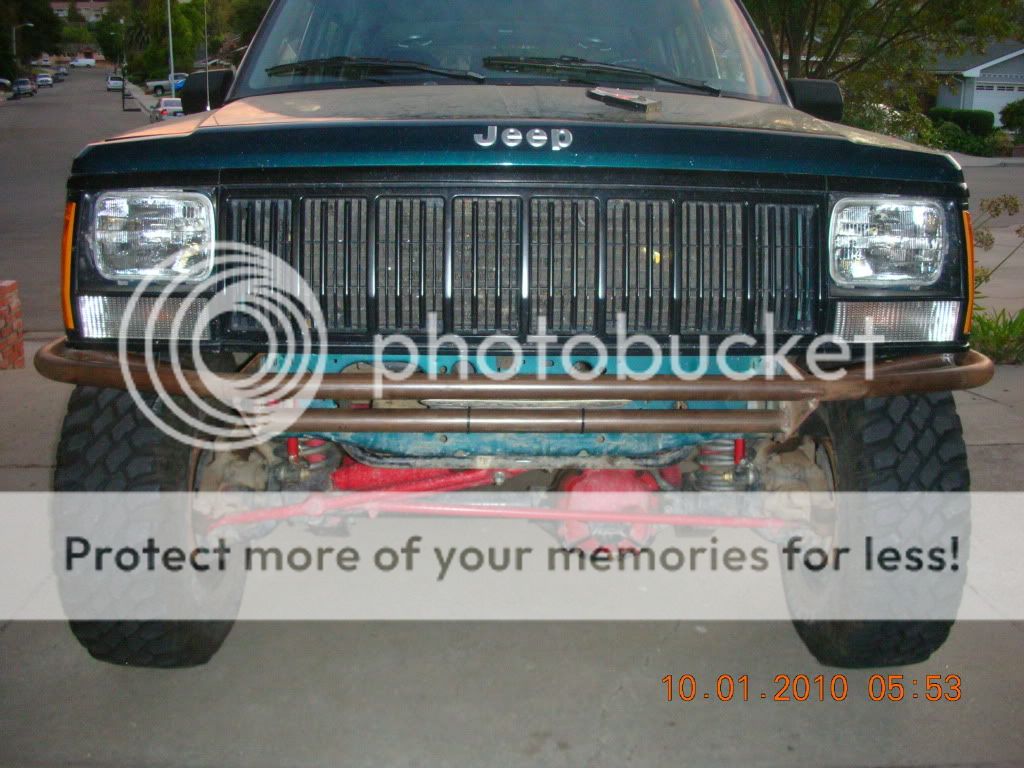

My most recent project has been a tube front bumper, capable of eventually holding a winch. Ive been working on it on and off for wayy too long, but I have learned a ton and have enjoyed doing it.

I started off with two pieces of 1/4" steel 5.5" wide, and 17" long. I notched the upper corners with a 1.5" hole saw to rest the tube in, and then cut a diagonal for clearance. I had to notch a bit off of the back end as well to fit around the sway bar.

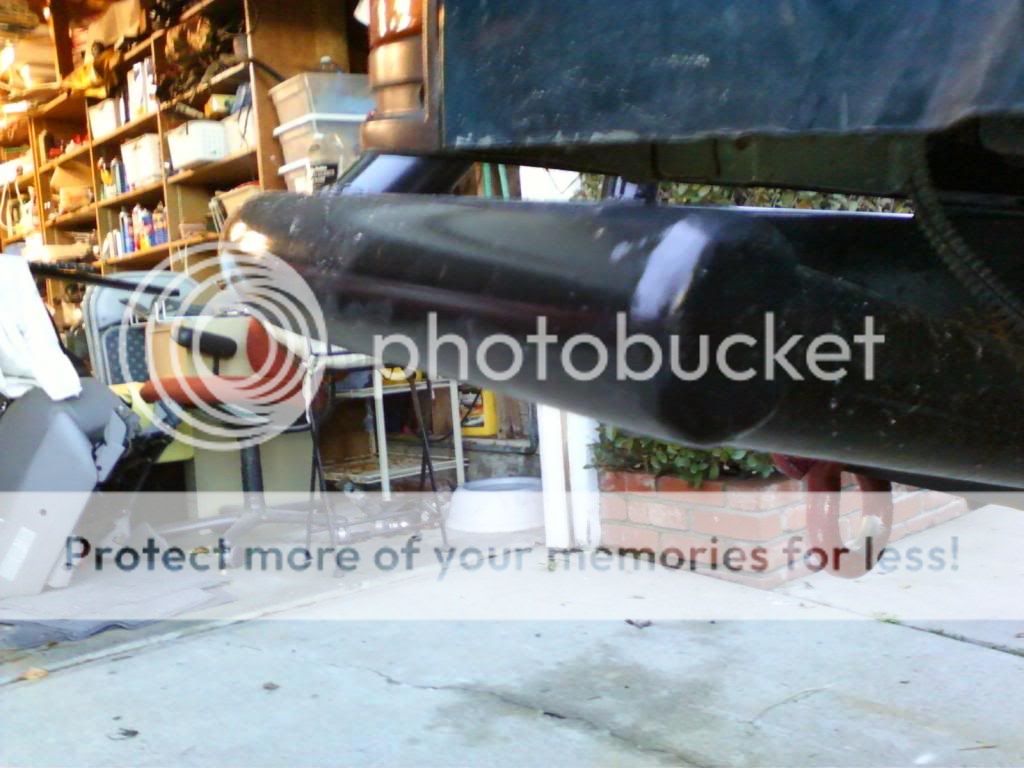

Cut a piece of tube. Can't remember how long off the top of my head.

Welded up some side supports to prevent the main tube from bending in the event of dropping down on a rock.

Sexy Notch

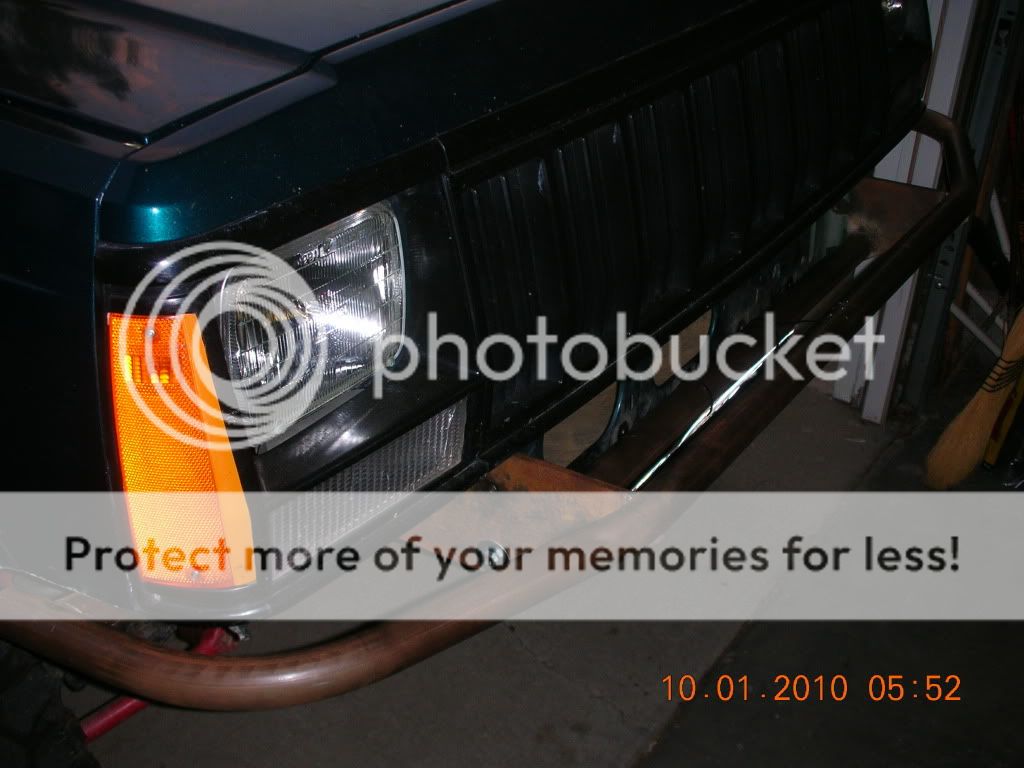

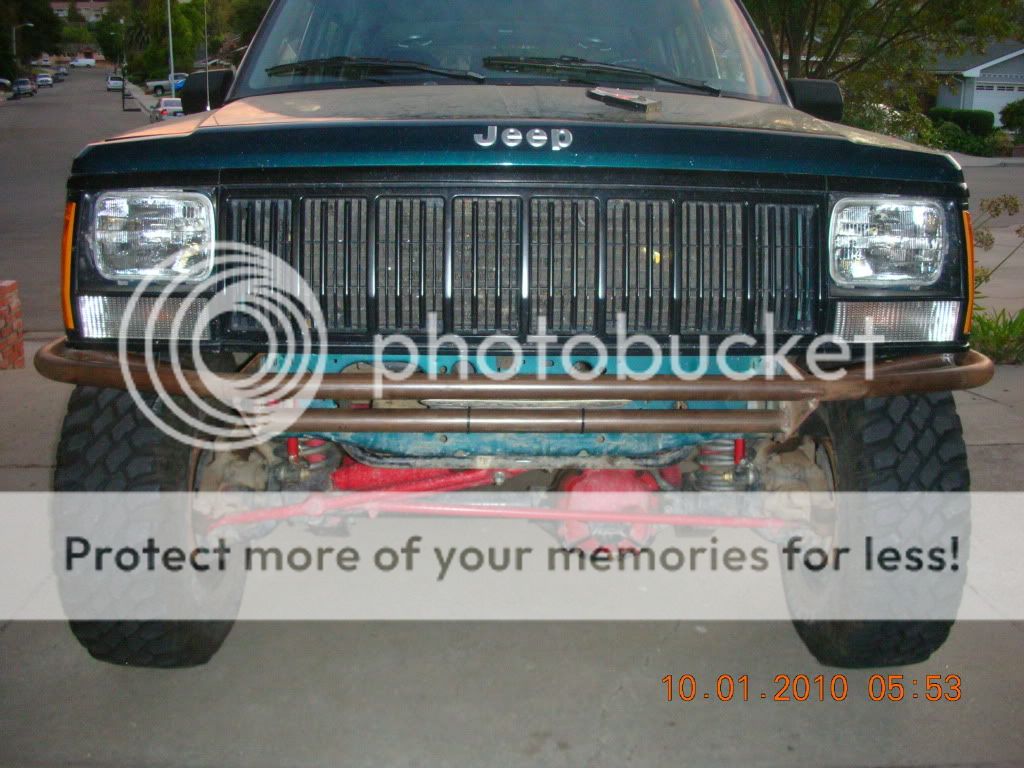

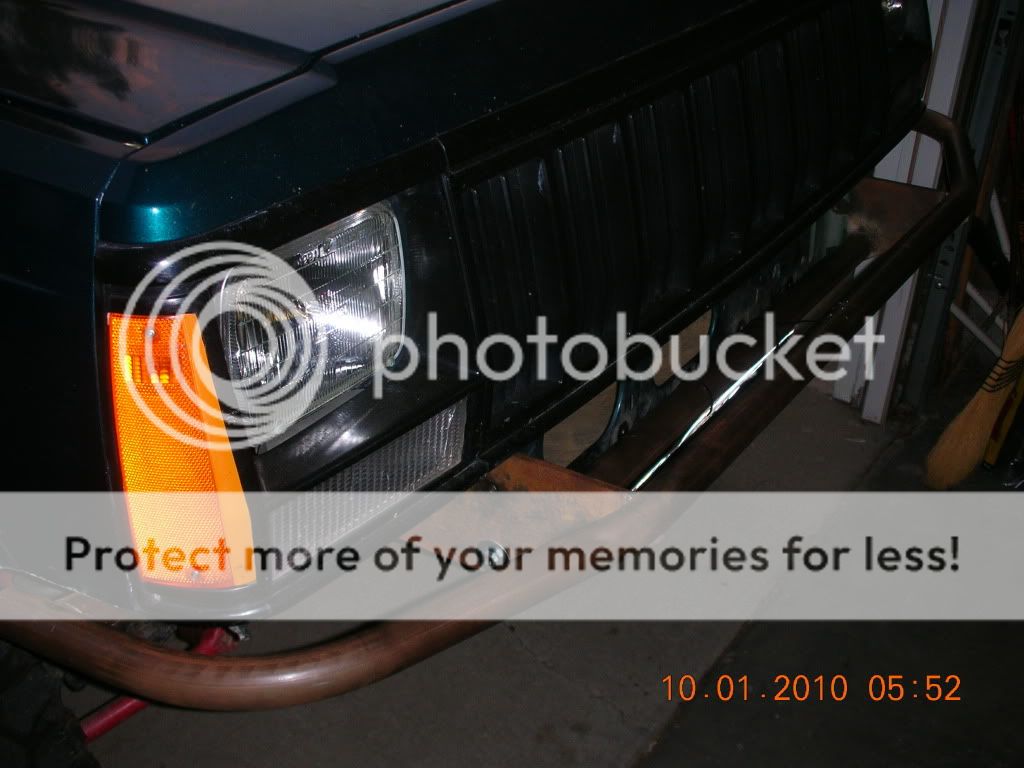

Then, we bent up the main bar. and cut a lower horizontal bar. It was mainly to hold the license plate at the time. It was finally starting to take shape.

Then started tacking it all up.

I started off with two pieces of 1/4" steel 5.5" wide, and 17" long. I notched the upper corners with a 1.5" hole saw to rest the tube in, and then cut a diagonal for clearance. I had to notch a bit off of the back end as well to fit around the sway bar.

Cut a piece of tube. Can't remember how long off the top of my head.

Welded up some side supports to prevent the main tube from bending in the event of dropping down on a rock.

Sexy Notch

Then, we bent up the main bar. and cut a lower horizontal bar. It was mainly to hold the license plate at the time. It was finally starting to take shape.

Then started tacking it all up.

Last edited: