userbmx1315

NAXJA Forum User

- Location

- Dallas, NC

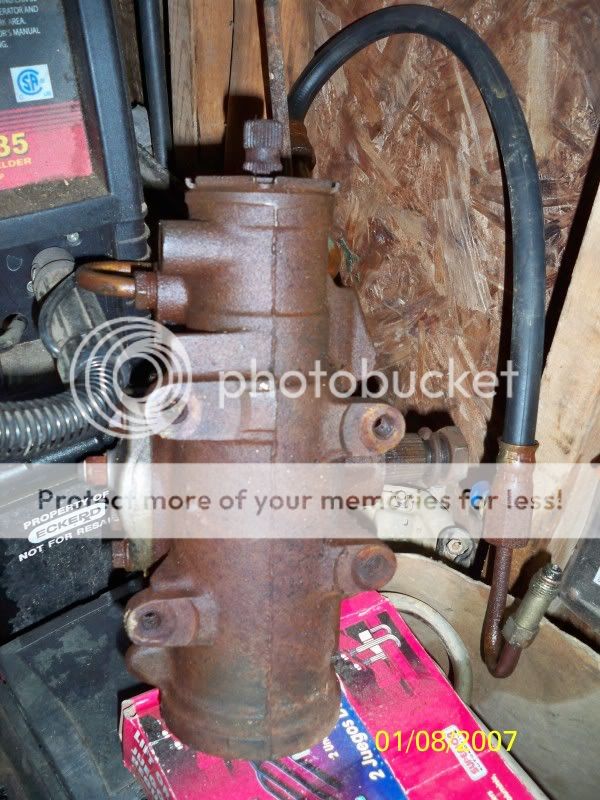

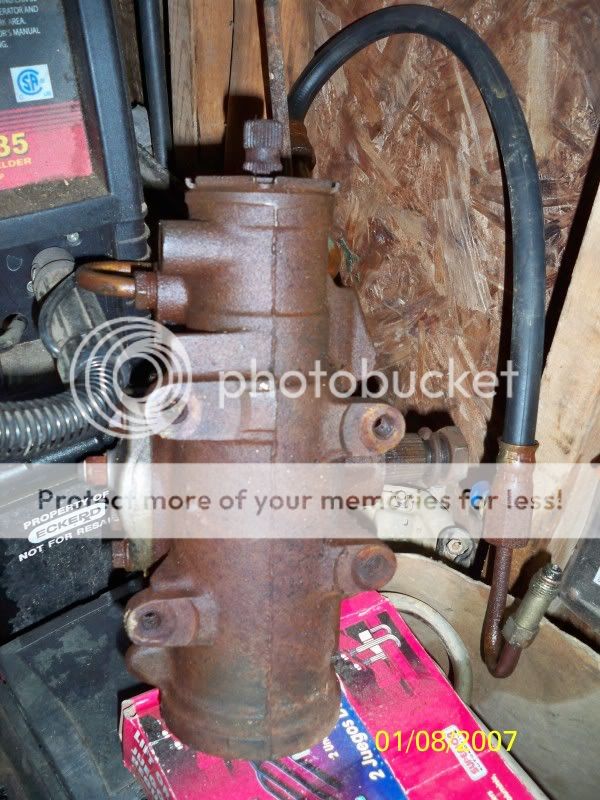

so i finally get some time in to my axle, geared, new ball joints (uppers and lowers), new pads, hub spacers, 3/4 heims, and some link made up. and going to run a yj steering box and a zj pitman arm

so far i'm trying to decide if i'm going to run the wj rotors redrilled and pay $100 each unit bearings or run the sport trac rotors (around 40 each)

questions tho. is the yj box bolt in other then the 4th hole?

looking on how i can stiffen it up.

pics of my set up so far. cause posts are worthless without pics

so far i'm trying to decide if i'm going to run the wj rotors redrilled and pay $100 each unit bearings or run the sport trac rotors (around 40 each)

questions tho. is the yj box bolt in other then the 4th hole?

looking on how i can stiffen it up.

pics of my set up so far. cause posts are worthless without pics