Well, for one thing, you're talking about the roll axis between the front and rear axles, which isn't calculated in the 3 link calculator, and so in my mind has nothing to do with this discussion.

The roll axis (or roll axis angle) between front and rear that you are referring to is based on what I am calling, and what the 3 link calculator refers to, and what your Google definititon calls the roll center height. The line between the front and rear roll center heights would be that roll axis. Since the calculator only deals with one axle at a time, that roll axis isn't part of the equation. Nor can it be calculated if there is no calculation on the XJ rear leaf suspension.

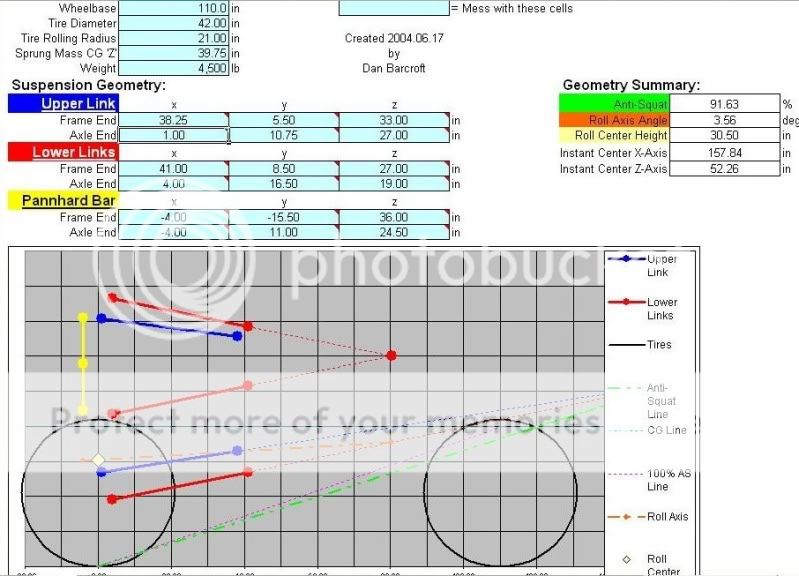

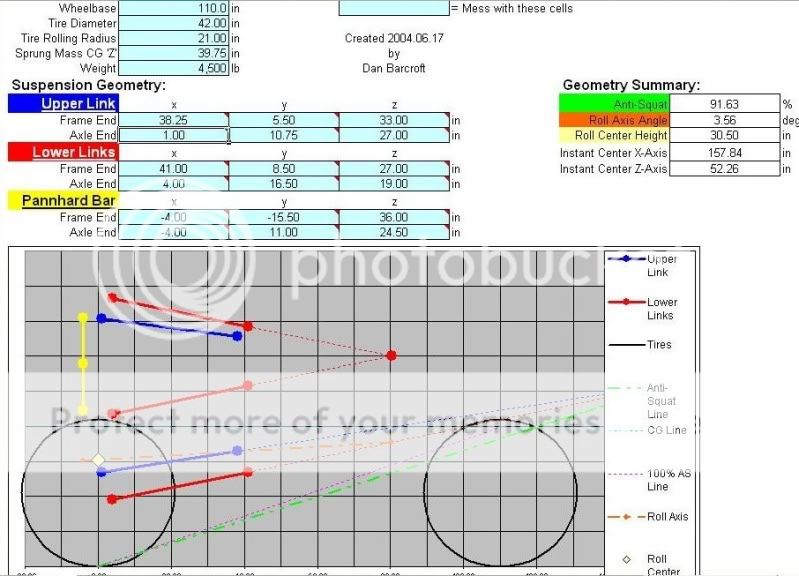

The roll axis angle that is referred to in the 3 link calculator is based solely on the link geometry of one axle, and is a measurement of the fore and aft axle movement under articulation that determines how much turn in of the tire there is. This can be important in a rear suspension, as too much roll axis angle, and resulting roll steer, can steer a rear tire off of the intended line. This is especailly important when driving a V or wall, where the rear tire can literally drive off the wall and drop into the hole. This is typical on a lifted short arm TJ which happens to have terrible roll steer/roll axis angle. This roll steer is the same as in your Google definition.

In our discussion, and in the calculator, roll axis angle refers to roll steer amount, which can't happen in the front since you're turning the tires and controlling the direction yourself. This is why I said it doesn't matter.

I discussed slightly the effects on handling of a high roll center, which we have the ability to control when setting up a suspension. Roll axis can't be determined on our XJ's (well, I guess if we had the calculation for a leaf spring suspension it could be), but goes along with the general concept of how a higher or lower role center effects road handling. A higher roll center reduces roll tendancy (what we'll call stability) but is less predictable, while a lower roll center height can allow more roll tendancy but is more predictable.........this matches the definition you posted of the effects of a higher or lower roll axis.

Good discussion. Maybe someone is getting something out of this.