Stallacrew

NAXJA Forum User

- Location

- Cullman, Alabama

Well a few months ago my dad and I bought a cherry little MJ. Only major problem was that it had no transmission in it. It has a bookoo of miles on it, but the engine was rebuilt "meticulously" 30k ago. I've known the guy that sold it to me for a while. I stopped in his driveway one day when I saw him working outside, and commented on his MJ, the first thing he said was "It's not for sale". I just wanted to tell him about  , which I did, and from then on out, we were Jeep buds.

, which I did, and from then on out, we were Jeep buds.

Long story short, bought a sweet 2wd MJ with a rebuilt Renix, missing it's Peugot tranny, and got a sweet set of leather seats in the deal. Now it was time for a transmission...

Crappy pic from night time, but the best I have:

Nice interior, no more than a year old, and also a free FSM!!

I had read on Novak about the SM465/SM420 and such but they required like $1000 in adaptor stuff, so I looked on. I have aperfectly good AW4 with a NP231 on the back of it sitting in the driveway, but we didnt want to deal with the electronics and whatnot. I told dad about Brett M's shifting, and he didnt like the sound if it so we kept looking and came across the NP435 idea.

Little did I know that in the driveway was also a T176 bellhousing that came with my 4.2L engine from last years stroker build. I checked it out, found that it would all peice together and got to work.

We found a complete NP435 transmission ~60 miles from home for $150 and talked him down to $125. This guy claims to know Rusty from Rusty's offroad. I don't know the validity to that story, but he was nice regardless.

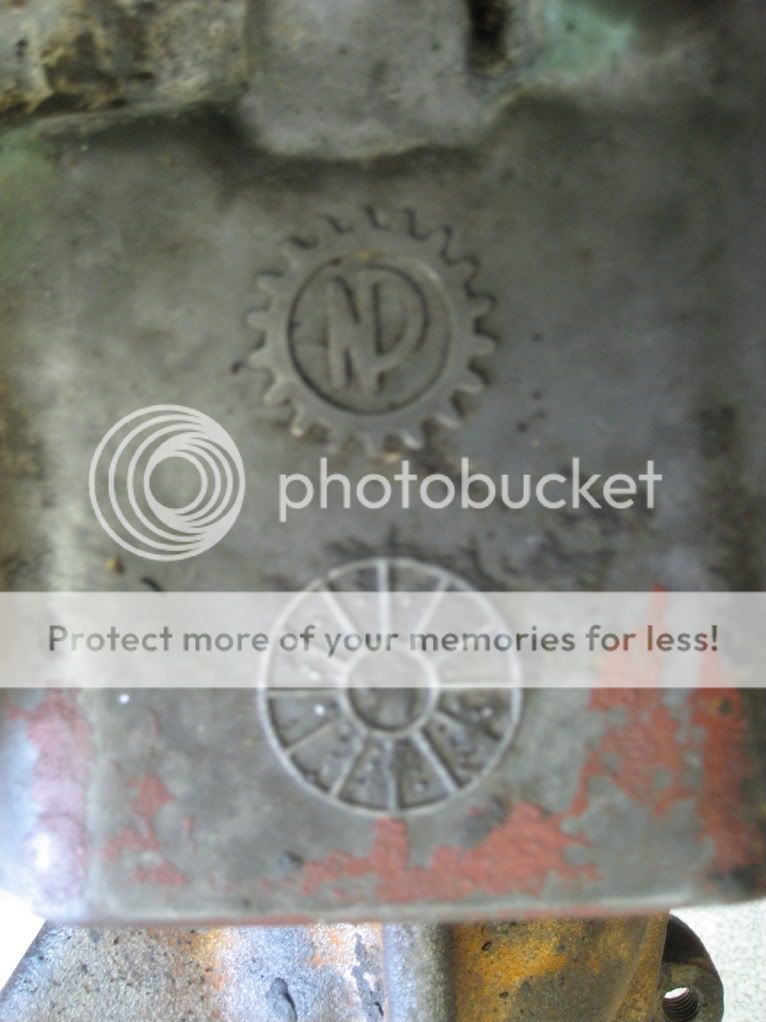

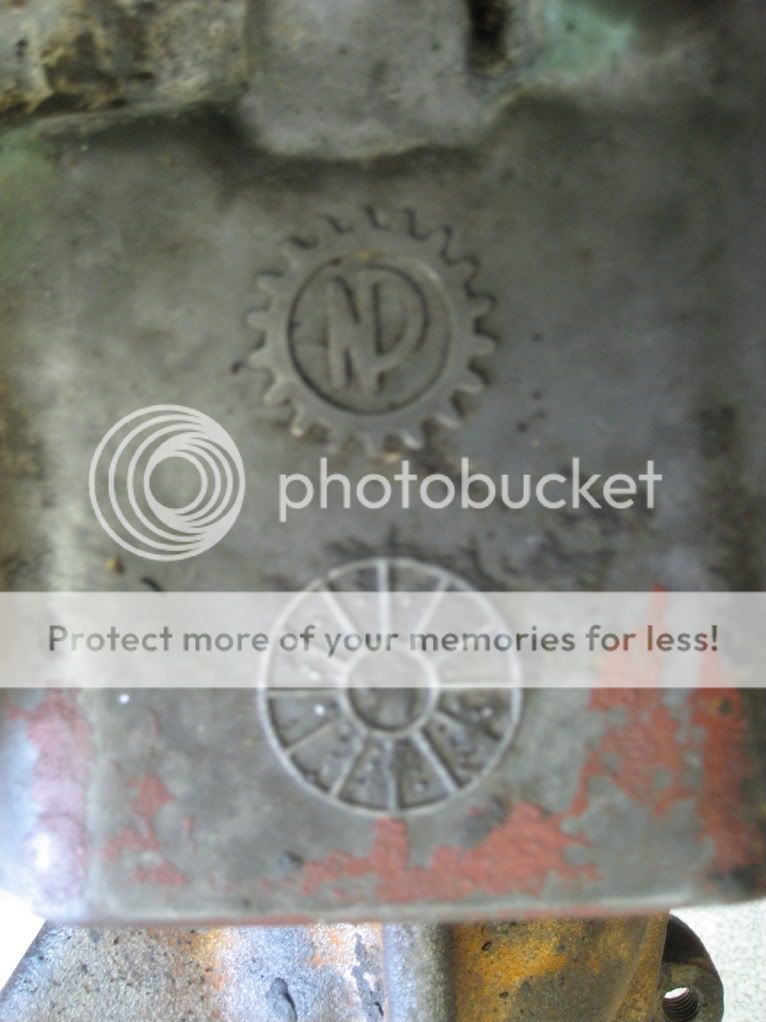

NP435:

Logo, which I want made into a sticker:

So now we needed to put a CPS hole precisely in the spot it needed to be to avoid sending it off to NOVAK.

We own a manufacturing co, and have machinery to make whatever we need....I haven't spent enough time to aquire all the skillz I need so dad did the majority of this work while I was still on the clock (come on he's the boss and can do whatever he wants). So when I got off work, I saw a fabulous looking CPS sensor mounting location.

I had to make some washers to put the sensor it the correct place, and to also index the bolt to the right spot since it had a shoulder on it.

Bolt:

Washer beginnings:

Washer in the CPS holes:

We also had to put mounting holes on the big flat area on the bellhousing. The T160 (i think) bellhousing requires no mods to put the NP435 in it, you just need the CPS hole and such. However, we had the T176 housing and we had to drill some holes. 2 of the holes were already piloted in, but not all the way through or tapped, so we had to do that. We also went ahead and used some set screws and blue loctite to plug the previous mounting holes so no crap would enter.

, which I did, and from then on out, we were Jeep buds.

, which I did, and from then on out, we were Jeep buds.Long story short, bought a sweet 2wd MJ with a rebuilt Renix, missing it's Peugot tranny, and got a sweet set of leather seats in the deal. Now it was time for a transmission...

Crappy pic from night time, but the best I have:

Nice interior, no more than a year old, and also a free FSM!!

I had read on Novak about the SM465/SM420 and such but they required like $1000 in adaptor stuff, so I looked on. I have aperfectly good AW4 with a NP231 on the back of it sitting in the driveway, but we didnt want to deal with the electronics and whatnot. I told dad about Brett M's shifting, and he didnt like the sound if it so we kept looking and came across the NP435 idea.

Little did I know that in the driveway was also a T176 bellhousing that came with my 4.2L engine from last years stroker build. I checked it out, found that it would all peice together and got to work.

We found a complete NP435 transmission ~60 miles from home for $150 and talked him down to $125. This guy claims to know Rusty from Rusty's offroad. I don't know the validity to that story, but he was nice regardless.

NP435:

Logo, which I want made into a sticker:

So now we needed to put a CPS hole precisely in the spot it needed to be to avoid sending it off to NOVAK.

We own a manufacturing co, and have machinery to make whatever we need....I haven't spent enough time to aquire all the skillz I need so dad did the majority of this work while I was still on the clock (come on he's the boss and can do whatever he wants). So when I got off work, I saw a fabulous looking CPS sensor mounting location.

I had to make some washers to put the sensor it the correct place, and to also index the bolt to the right spot since it had a shoulder on it.

Bolt:

Washer beginnings:

Washer in the CPS holes:

We also had to put mounting holes on the big flat area on the bellhousing. The T160 (i think) bellhousing requires no mods to put the NP435 in it, you just need the CPS hole and such. However, we had the T176 housing and we had to drill some holes. 2 of the holes were already piloted in, but not all the way through or tapped, so we had to do that. We also went ahead and used some set screws and blue loctite to plug the previous mounting holes so no crap would enter.