jordo

NAXJA Forum User

- Location

- Port Dover ON

yeah, up here dealer and napa premium replacements are almost $300 ea all said and done. iirc 89 and down came with a rebuildable hub while anything newer is non servicable. remember something about needle bearing vs ball bearing too.

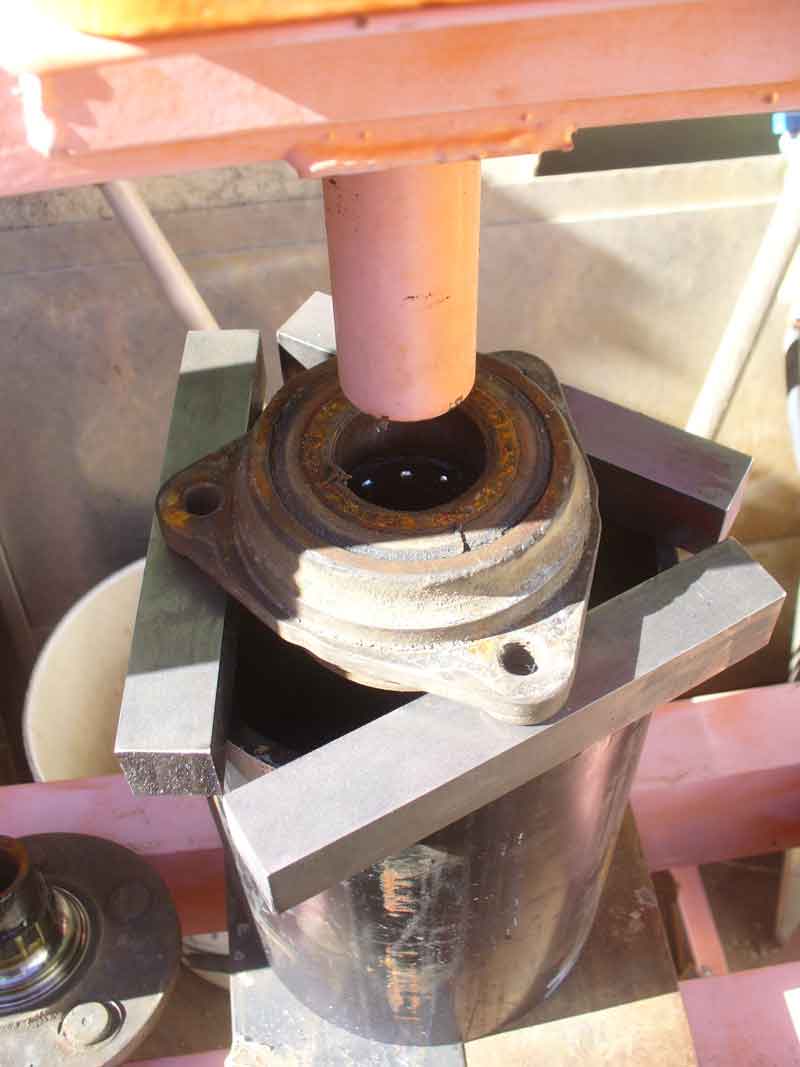

mine's a 90 and didn't have the choice to rebuild but on a coworkers 88 he decided it'd be quicker just to grab replacements than get them rebuilt. guess if you can do it yourself it'd be less of a deal. a 4lb brass mallet makes short work of removing a stubborn hub. once the new one's in with some antiseize your set.

mine's a 90 and didn't have the choice to rebuild but on a coworkers 88 he decided it'd be quicker just to grab replacements than get them rebuilt. guess if you can do it yourself it'd be less of a deal. a 4lb brass mallet makes short work of removing a stubborn hub. once the new one's in with some antiseize your set.