- Location

- New Jersey

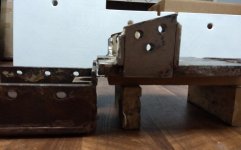

Got a project where I need to repair and strengthen a load bearing backing plate assembly fabricated with several pieces of 1000 and 1100 series steel.

Couple of questions if you happen to be familiar with and have worked with the stuff:

Can I MIG weld it, single and multipass? If so, recommended wire and gas?

Are there other steels that can be welded to it with a compatible wire? If so, what steel type and wire type?

Anything odd versus mode common steel types that I should be aware of?

Thanks.

--Matt

Couple of questions if you happen to be familiar with and have worked with the stuff:

Can I MIG weld it, single and multipass? If so, recommended wire and gas?

Are there other steels that can be welded to it with a compatible wire? If so, what steel type and wire type?

Anything odd versus mode common steel types that I should be aware of?

Thanks.

--Matt

, the ones I attached to this post are the best I can do.

, the ones I attached to this post are the best I can do.