Jump This

Just another minion!

- Location

- Borrego Springs Ca.

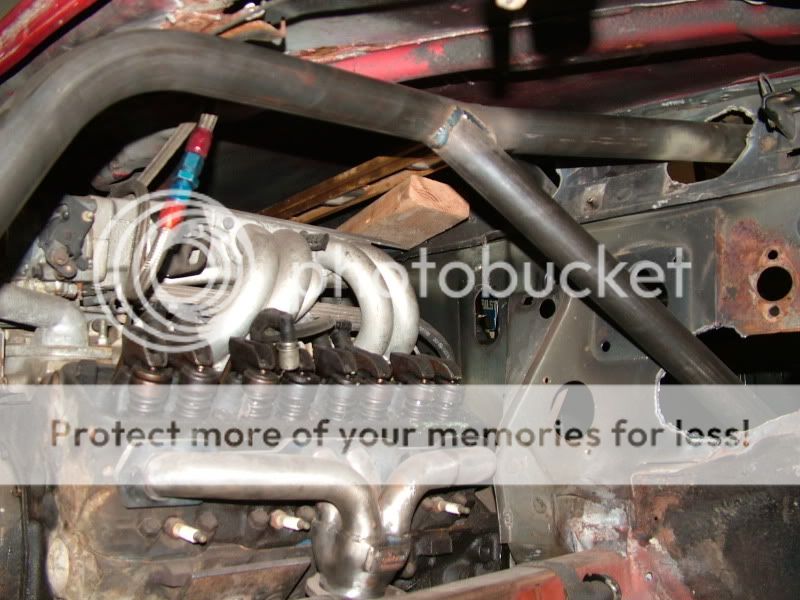

When looking into the entire roll cage issue, it becomes evident there are a lot of schools of thaught.

The halo, supported along the pilllars.

The pillar hoops, connected by stanctions along the roof line.

Combos. A pillar loop with 'U' roof line supported with b and c legs....

Etc. Etc.

What were the issues you ran into building your cages?

My rig will be full bodied, well, almost full bodied.

At present I am thinking of building using a combo approach.

A hoop with a 'U' shaped roof, with supports on the b and c pillars then running angled supports to the above the rear leafs.

If it helps, I'm not new to cage building. I know how to build a cage that will allow for 360* welds along each section. Although I have never built a cage for a Cherokee.

Don't give me too much crap about searching, I'm a cripple for a few more days and sitting in front of this computer hurts my back!!

TIA

Rick

The halo, supported along the pilllars.

The pillar hoops, connected by stanctions along the roof line.

Combos. A pillar loop with 'U' roof line supported with b and c legs....

Etc. Etc.

What were the issues you ran into building your cages?

My rig will be full bodied, well, almost full bodied.

At present I am thinking of building using a combo approach.

A hoop with a 'U' shaped roof, with supports on the b and c pillars then running angled supports to the above the rear leafs.

If it helps, I'm not new to cage building. I know how to build a cage that will allow for 360* welds along each section. Although I have never built a cage for a Cherokee.

Don't give me too much crap about searching, I'm a cripple for a few more days and sitting in front of this computer hurts my back!!

TIA

Rick