NW99XJ

NAXJA Forum User

- Location

- Gresham, Or.

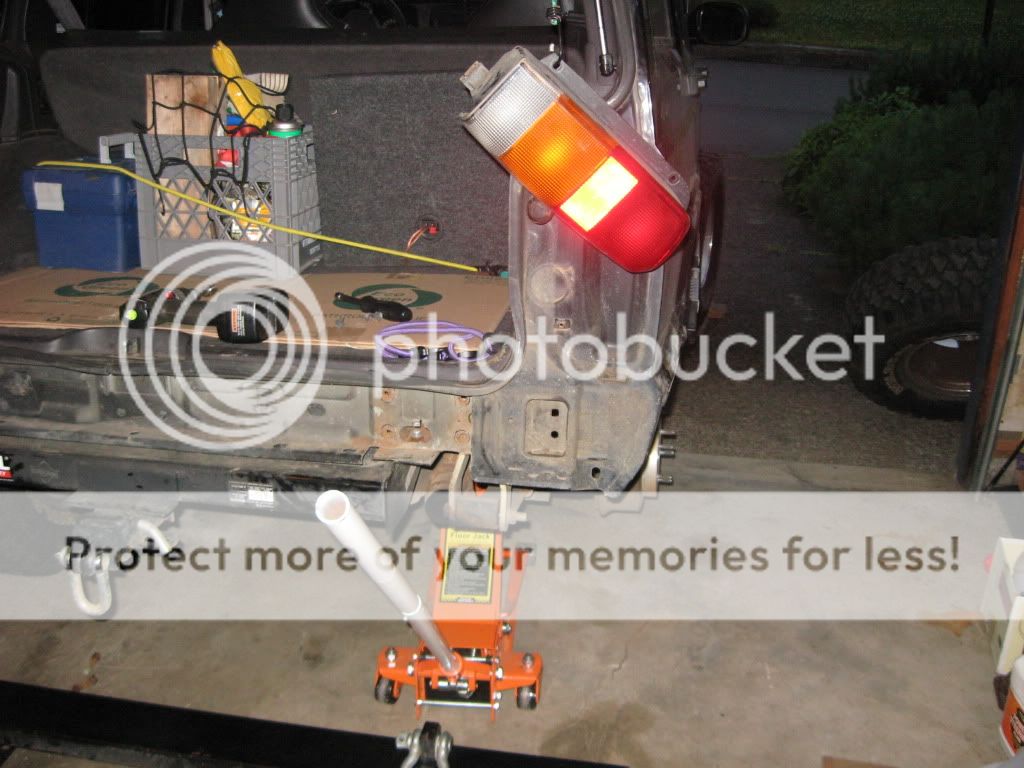

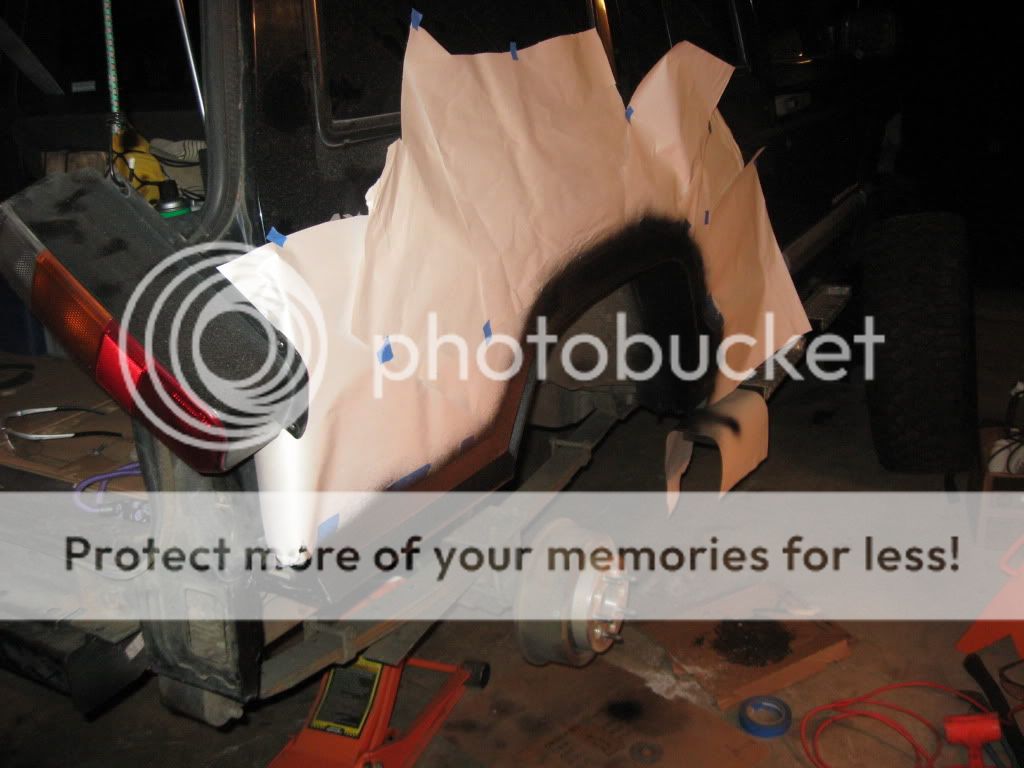

Now it was time to get the Spartan Locker into the diff of the D30. With the carrier and stuff on the work bench I went to task following the instructions I downloaded. I was hoping I wasnt going to have to remove the ring gear....

First to come out was the pin holding the cross pin in place:

With that out the spider gears came right out:

I started cleaning up the locker, getting it ready for its new home. Took it all apart, cleaned each piece real good, and noticed something that I really should have caught before.....

The spacers had been thru hell....The guy told me that he had incorrectly installed it... leaving the thrust washers in, when you're clearly not supposed to. It broke the cross pin he installed, and he just decided to off it to someone else, rather than deal with it. Hence the need for me getting a new cross pin shaft. I didn't mind spending the $20 for one of those, and the rest of the locker looks fine, but these spacers, are just shot. Some of these cracks go all the way thru, and there's no chance in hell i'm going to assume these wont grenade in my differential and take everything else out with it.

They're in just too bad a shape for me to install, so with a heavy heart, and an angry temper, I put my differential back together, and re-installed it. Re-checked the backlash (was only off by a couple thousandths than before.)

The axles went back in, and the diff was buttoned up and re-filled. Been a week now, and not a drop has leaked. So the seals are doing just fine.

>

In the mean time, i've ordered a new set of springs and pins for the Spartan, from Bell Offroad out of Bellingham Wa. (gotta support the NW!) -they came in three days flat, and the price couldn't be beat anywhere.

>

And since my day job is sitting in front of a computer, engineering and designing tooling solutions for the electronics manufacturing industry, I took it upon myself to mic-out the spacers, and draft up a design for a set of replacements. (I couldn't find a set anywhere to buy - so why not just make them!) - We have a machine shop here, and my cost is only going to be for the hardened tool steel. The design time is, well, mine, and the machining time is free. Cant argue with that, Here's the model I've got:

I should have the new set of spacers done sometime this week, and be ready to put them in before a (possible) shake down run this weekend.

First to come out was the pin holding the cross pin in place:

With that out the spider gears came right out:

I started cleaning up the locker, getting it ready for its new home. Took it all apart, cleaned each piece real good, and noticed something that I really should have caught before.....

The spacers had been thru hell....The guy told me that he had incorrectly installed it... leaving the thrust washers in, when you're clearly not supposed to. It broke the cross pin he installed, and he just decided to off it to someone else, rather than deal with it. Hence the need for me getting a new cross pin shaft. I didn't mind spending the $20 for one of those, and the rest of the locker looks fine, but these spacers, are just shot. Some of these cracks go all the way thru, and there's no chance in hell i'm going to assume these wont grenade in my differential and take everything else out with it.

They're in just too bad a shape for me to install, so with a heavy heart, and an angry temper, I put my differential back together, and re-installed it. Re-checked the backlash (was only off by a couple thousandths than before.)

The axles went back in, and the diff was buttoned up and re-filled. Been a week now, and not a drop has leaked. So the seals are doing just fine.

>

In the mean time, i've ordered a new set of springs and pins for the Spartan, from Bell Offroad out of Bellingham Wa. (gotta support the NW!) -they came in three days flat, and the price couldn't be beat anywhere.

>

And since my day job is sitting in front of a computer, engineering and designing tooling solutions for the electronics manufacturing industry, I took it upon myself to mic-out the spacers, and draft up a design for a set of replacements. (I couldn't find a set anywhere to buy - so why not just make them!) - We have a machine shop here, and my cost is only going to be for the hardened tool steel. The design time is, well, mine, and the machining time is free. Cant argue with that, Here's the model I've got:

I should have the new set of spacers done sometime this week, and be ready to put them in before a (possible) shake down run this weekend.