MSLD

NAXJA Forum User

- Location

- Onatario, Canada

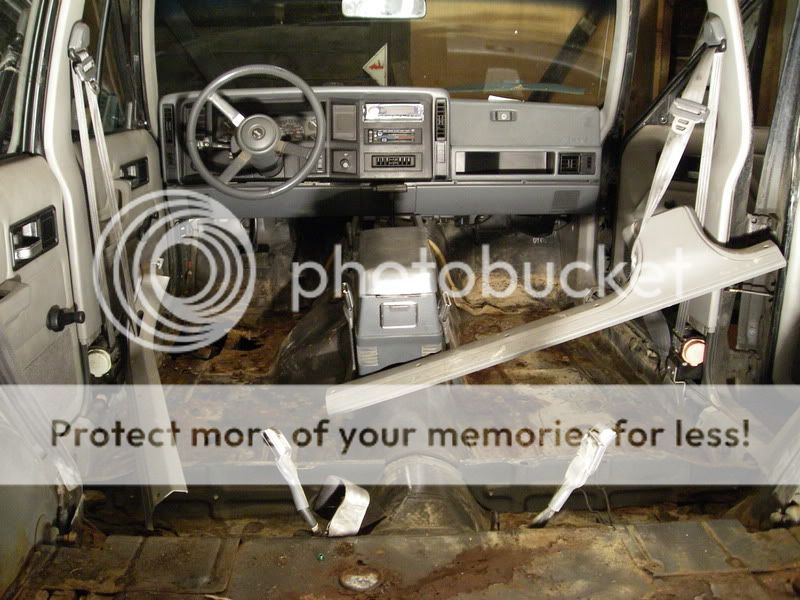

My floor is cut out, rocker are also cut out and I just ordered 16 ga sheets for a replacement Way cheaper than floor pans and will be much stronger (rust resistant). I had the shop put a 90 dgree bend that will run along the inside of the door sil (rust ate some of inside and all of my rockers) so I have a good surface upon which to weld. The rest of the shaping will be done by me. I will also be fabing new rockers. I have a Miller 180 w/argoshield that I will use to burn the new floors in. Looking for input on:

1)What is the best seam sealer to use?

2)For those who have done this with 16 ga...any advice before I hit it?

Thanks

Matt

1)What is the best seam sealer to use?

2)For those who have done this with 16 ga...any advice before I hit it?

Thanks

Matt