XJensen

NAXJA Forum User

- Location

- Sacramento

Finished up my rockers a few weeks ago so I figure its time to share. The only thing I would do differently is to keep the rocker at a flatter angle. I placed mine at 4° while 1-2 would have been fine.

I took a similar approach as Eric with a few changes along the way.

Materials:

2x6 3/16

2x2 1/8

3" 1/8 stock

1 1/2" angle 3/16

1" angle 1/8

3" 3/16 stick for capping the ends of the rails

I welded everything up with 220 .030 flux core. It worked fine on the thin stuff just had to be very careful. This was my first welding project and I am very happy with it.

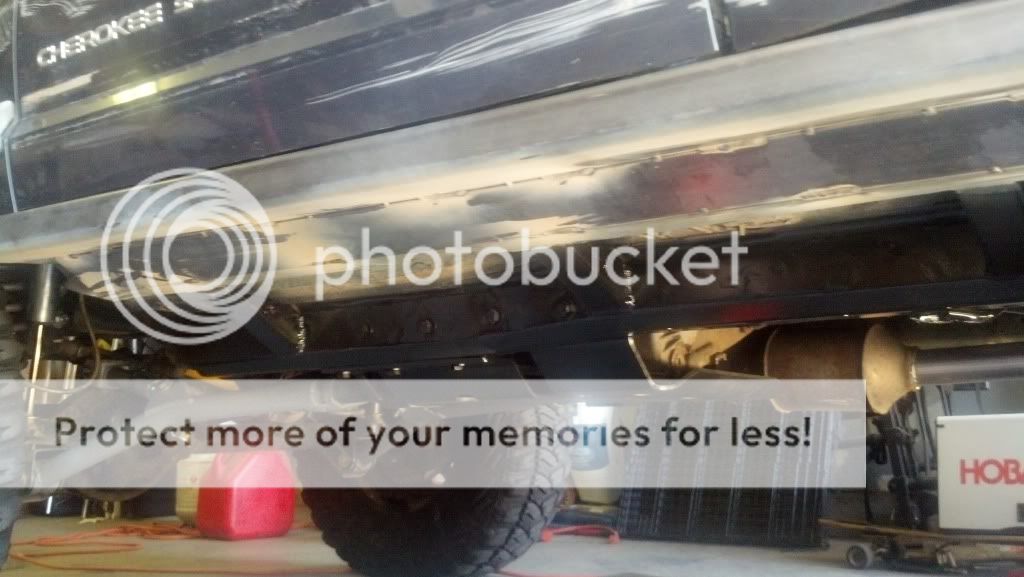

On to the pictures - old rails

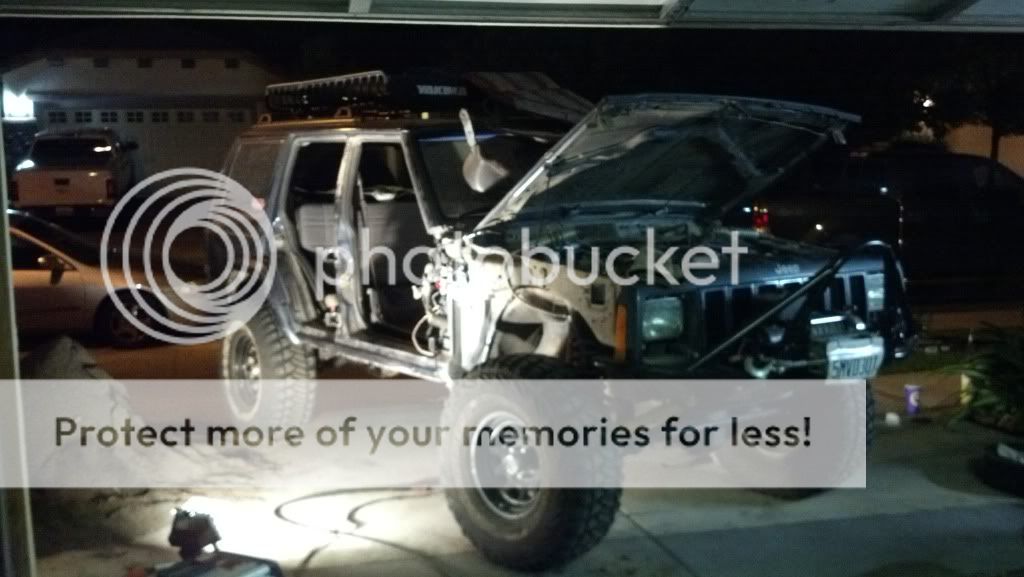

Got the doors and fenders off

More to come....

I took a similar approach as Eric with a few changes along the way.

Materials:

2x6 3/16

2x2 1/8

3" 1/8 stock

1 1/2" angle 3/16

1" angle 1/8

3" 3/16 stick for capping the ends of the rails

I welded everything up with 220 .030 flux core. It worked fine on the thin stuff just had to be very careful. This was my first welding project and I am very happy with it.

On to the pictures - old rails

Got the doors and fenders off

More to come....