Justpunchit

NAXJA Member #1291

- Location

- Jaffrey, NH

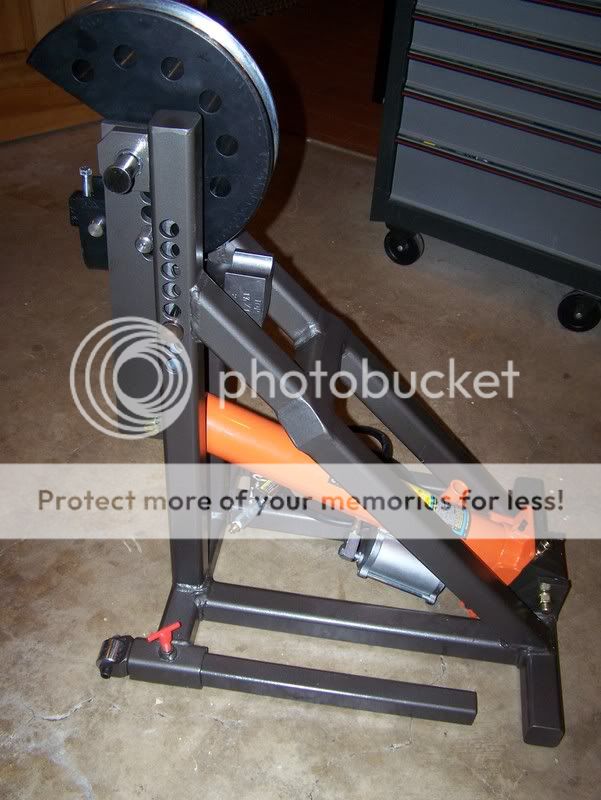

Thought I'd document this I really haven't found alot here so it couldn't hurt to add to it. The bender I'm making will be the Gottrikes version found here;

http://www.gottrikes.com/Tube_Bender.htm

Before I get started for the few that have made this is there anything they modified to there's that turned out to be really beneficial? He hasn't updated the plans since 2007 so I'm just making sure there wasn't improvements to be made. I plan on tweaking things a little but nothing really drastic.

http://www.gottrikes.com/Tube_Bender.htm

Before I get started for the few that have made this is there anything they modified to there's that turned out to be really beneficial? He hasn't updated the plans since 2007 so I'm just making sure there wasn't improvements to be made. I plan on tweaking things a little but nothing really drastic.