bcmaxx

NAXJA Forum User

- Location

- The West Kootenays,B.C. Canada

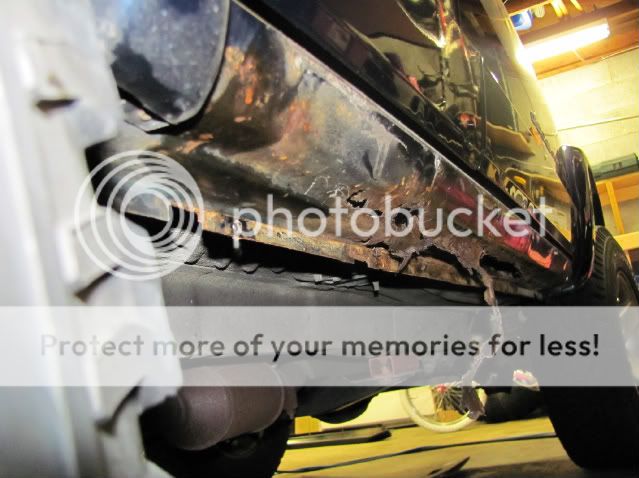

Well the rockers werent worth protecting, So before my superrails go on I decided to replace my rocker panels. Boy I had no idea it was going to be as big of a job as it is! Front doors are half doors with the "hinge fix" so no problem there. The rears were a bugger, cant get a ratchet in on the torx fasteners! (I will be using normal hardware on re-assembly). I had to remove the seatbelt retractors to get access the wiring connector for the rear doors, and the passenger side has no connector,wtf? Had to cut the wiring for now, will solder it back together later. Now comes the painstaking task of centerpunching and drilling all the spot welds, there plenty! Now if you got them all you can start prying the old rocker off, I had to drill out a few hidden spot welds. I found some surface rust on the inside of the inner rockers, removed all the loose stuff and used rust convertor on it, I also found some pretty good cancer where the rocker meets the inner rear wheel well I'll have to address once the panels are spot welded in. Heres a few pics of my progress so far:

I'll get some more pics of my progress tommarow, and next time someones getting paid to do this!

I'll get some more pics of my progress tommarow, and next time someones getting paid to do this!