Muddy98

NAXJA Forum User

- Location

- Medford, OR

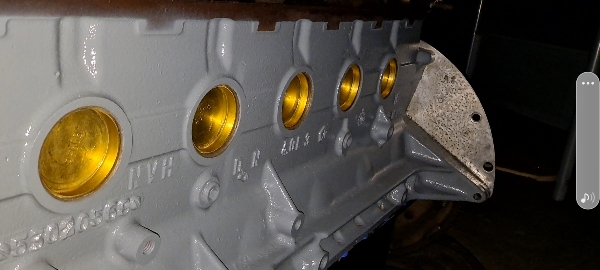

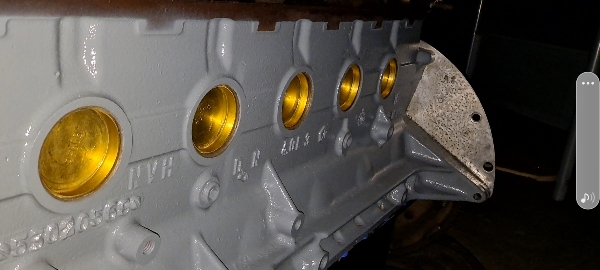

Okay pics suck but iv installed new freeze plugs all around and worried some are too much of an angle and probably gonna pull the one on the back of head because it's got a dent and its angled  just looking for some feedback.. now I have 4 stainless ones I can install but I'm worried this is gonna happen again so i know if I'm good the way they are or? I bought the melling kit from amazon and they were a pain to install more than usual because i think they are slightly oversized by a thousands or something and using a socket I had to really hammer them in hard just to get then to start took me a half a day. I had to redo 2 of them and use stainless on the rear ones behind the flex plate that I got from the autostore just because I was uncomfortable with them but yeah i suck at freezeplugs..

just looking for some feedback.. now I have 4 stainless ones I can install but I'm worried this is gonna happen again so i know if I'm good the way they are or? I bought the melling kit from amazon and they were a pain to install more than usual because i think they are slightly oversized by a thousands or something and using a socket I had to really hammer them in hard just to get then to start took me a half a day. I had to redo 2 of them and use stainless on the rear ones behind the flex plate that I got from the autostore just because I was uncomfortable with them but yeah i suck at freezeplugs..

The last 2 photos are the one on the back of the head and the picture before that is one that's on the side witg a slight dent.

Sent from my SM-A516U using Tapatalk

The last 2 photos are the one on the back of the head and the picture before that is one that's on the side witg a slight dent.

Sent from my SM-A516U using Tapatalk