alex22

NAXJA Forum User

- Location

- CT: waterbury area

So I picked up another XJ a month or so ago that needed a new head, its an 01 and the head was not repairable. I had planed on just doing a quick head swap, but the more I looked the less I liked so out came the engine. The cam was starting to wear, rings were shot, expansion plugs were almost rotted through, pistons were scuffed badly and the timing chain was slopped out. The crankshaft main journals were at minimum spec, main housing bores were at maximum and the factory put in a half set of .001 under bearings. But other than that it was great...

New parts and labor:

Clean and magnaflux.

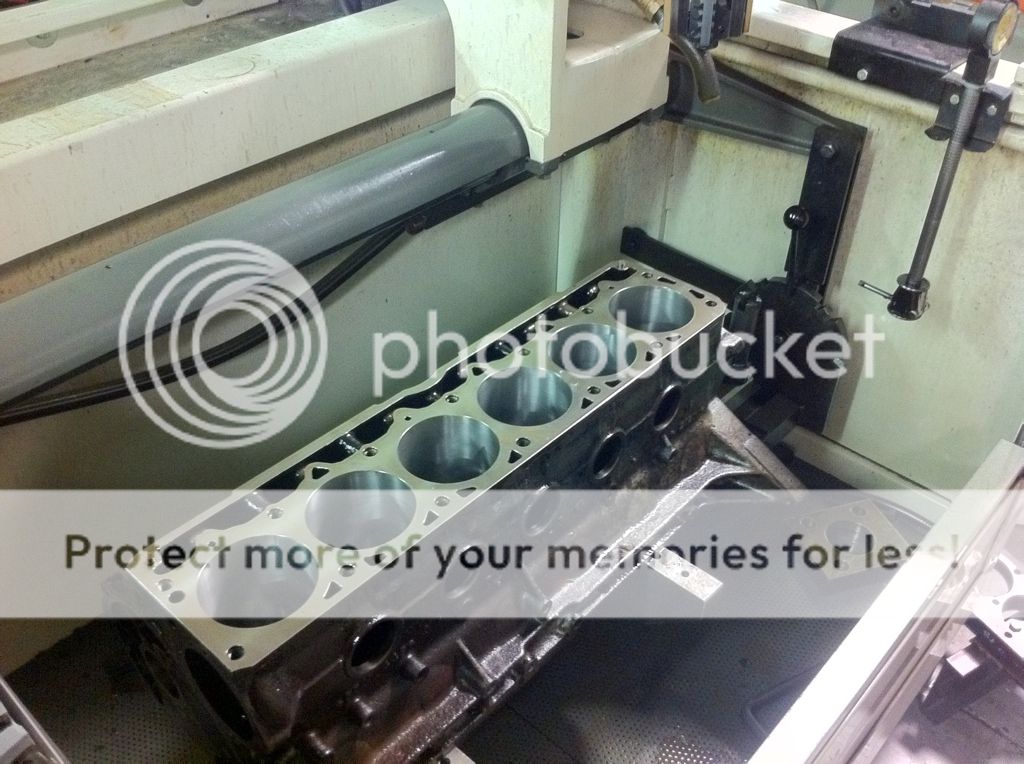

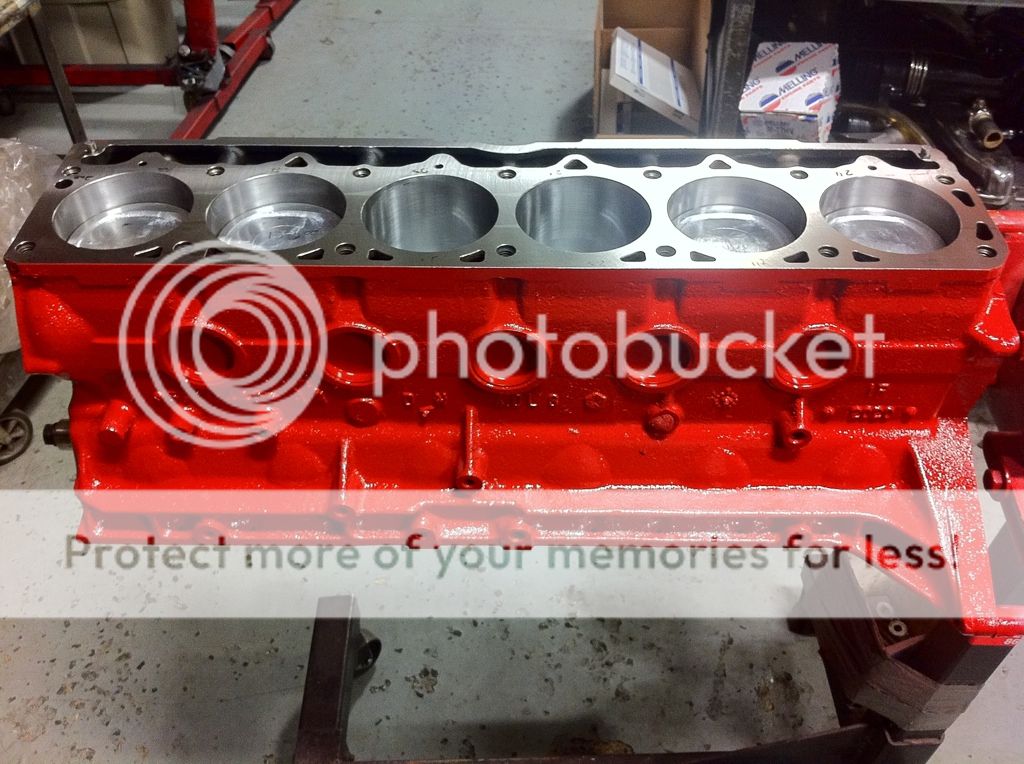

Block was align honed to minimum spec so I can use STD bearings without Excessive oil clearances.

Balanced rotating XXXembly.

ARP rod bolts.

.020 over Speed Pro pistons

Block decked to bring the pistons to about .005 in the hole for 9:1 compression and tighten the squish.

Comp Cams 68-232-4

Pre 1997 timing set and bolt with spring loaded pin.

Mopar performance valve springs & retainers

New head casting with some porting and chamber cleanup and performance valve job.

Ebay SS header and high flow precats.

Magnaflow high flow cat and Dynomax catback

AFE intake.

4 hole injectors.

Will moving the IAT sensor into the intake tube/airbox or an adjustable MAP be enough to keep the A/F ratio correct with the breathing mods?

Will 19lb injectors be enough for this?

Can the Mopar Performance valve springs and hardened locks be used with the late style 3 groove keepers or do I have to get the older style valves and use single groove hardened keepers?

~Alex

no, this will not become a stroker.

New parts and labor:

Clean and magnaflux.

Block was align honed to minimum spec so I can use STD bearings without Excessive oil clearances.

Balanced rotating XXXembly.

ARP rod bolts.

.020 over Speed Pro pistons

Block decked to bring the pistons to about .005 in the hole for 9:1 compression and tighten the squish.

Comp Cams 68-232-4

Pre 1997 timing set and bolt with spring loaded pin.

Mopar performance valve springs & retainers

New head casting with some porting and chamber cleanup and performance valve job.

Ebay SS header and high flow precats.

Magnaflow high flow cat and Dynomax catback

AFE intake.

4 hole injectors.

Will moving the IAT sensor into the intake tube/airbox or an adjustable MAP be enough to keep the A/F ratio correct with the breathing mods?

Will 19lb injectors be enough for this?

Can the Mopar Performance valve springs and hardened locks be used with the late style 3 groove keepers or do I have to get the older style valves and use single groove hardened keepers?

~Alex

no, this will not become a stroker.