- Location

- NJ, U.S.A.

It would be best to remove it.

I'd like nothing better than to get it out of there, but so far I've been unsuccessful in getting to even budge.

I did re-read your bumper thread last night, saw that pic of the plate. I also read the text on how you got the thing out of there (hence the edit to my last post). That leaves me with two questions for you:

1. Since I don't have a plasma cutter, do you think that if I were to get a Dremel cutting wheel in there to make small cuts down through the frame rail at the welds, then go under the rail and grind back "under" the plate slightly, would that likely compromise the welds enough that I could finally hammer it loose?

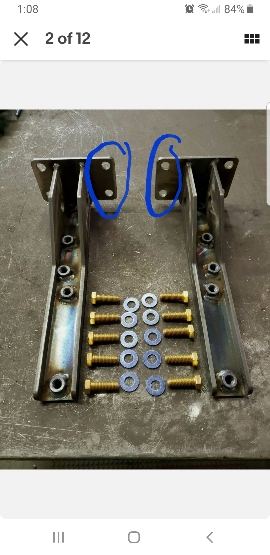

2. When you plasma cut the welds on yours, did those cuts go all the way through the rail? If so, did you weld those shut again or just treat to prevent rust and assume that the box-tube inserts that hold your bumper on would make up for the "lost strength"? I don't have a welder either, but plate appears to fall between the last two bolts on my so ultimately the cuts would be sandwiched between them and my new gas tank skid. I'm a little concerned about compromising the strength of the rail, but with the bracket inside and the skid outside, maybe I'm over-thinking.

Appreciate your thoughts!