88manche

NAXJA Forum User

- Location

- Portland, Oregon

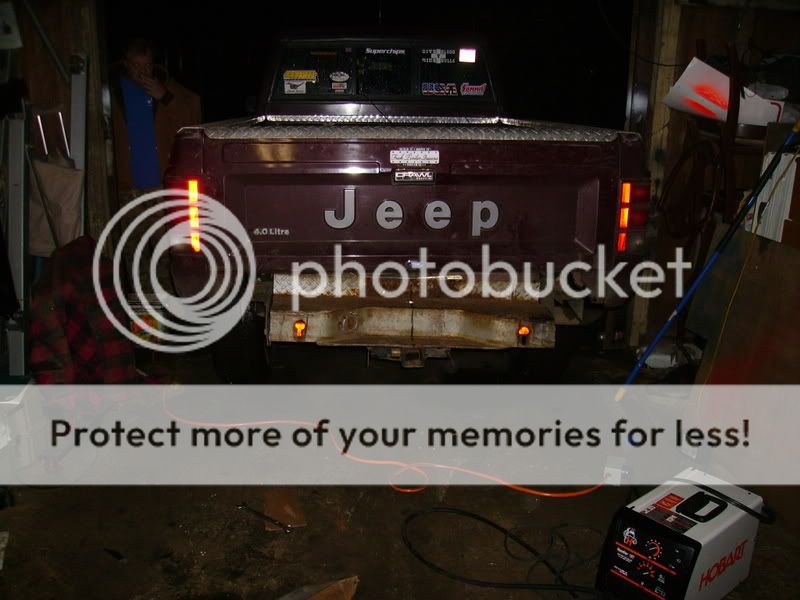

I know this will be irrelevant to most here, as it is going on an MJ and not an XJ, but oh well. Anyway, this is my first build.

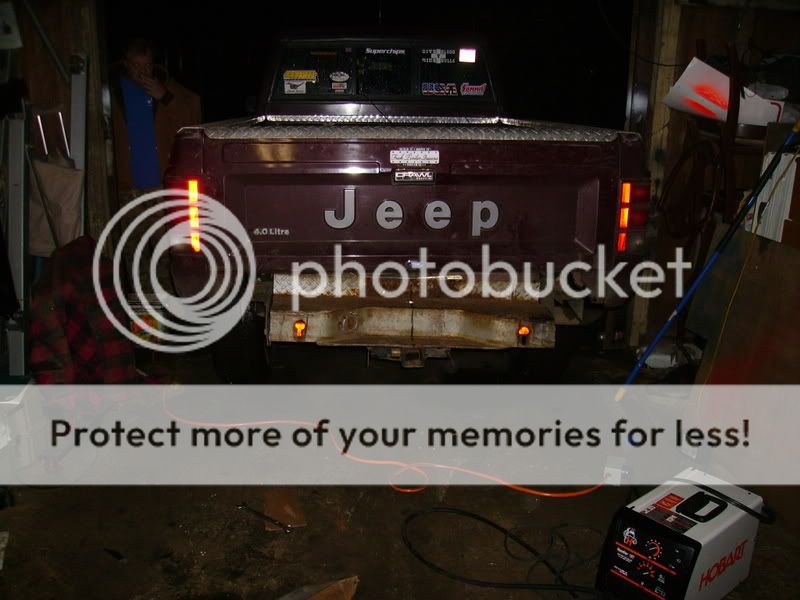

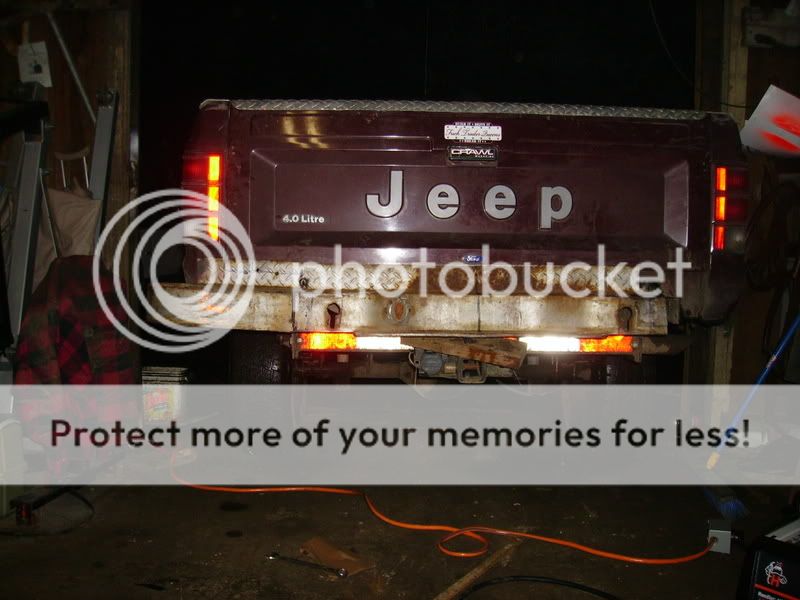

Well, I decided that I didn't like my old flimsy stock bumper, and I had an old bumper from a hot rod project. I got a welder for Christmas and I was bored, so things clicked. Heres my build.

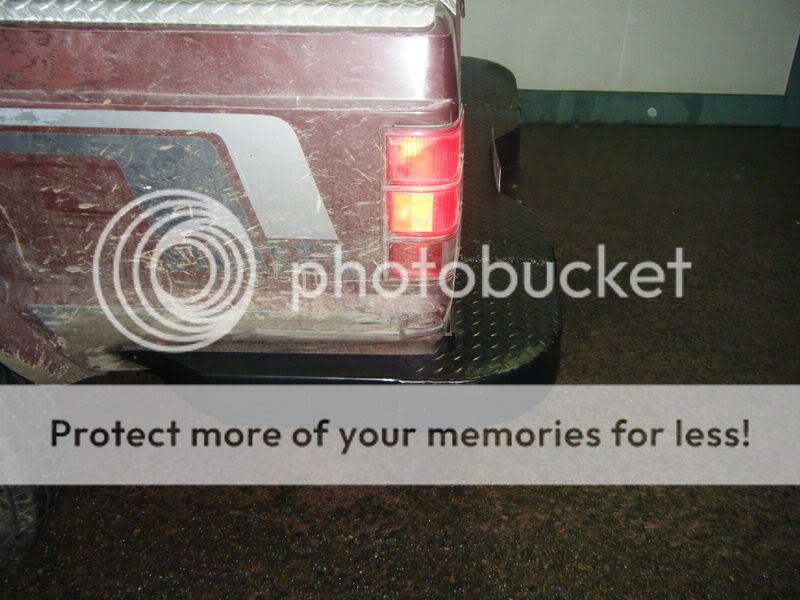

Heres the bumper. Outside width is 74'' wide, about 10'' wider than the stock MJ bumper. Most of that was the extra metal. The bumper brackets needed to be cut out and replaced. I needed to cut down the bumper a total of 5'' (2.5'' each side) to make it fit. It is made out of 1/8’’ and 3/8’’ plate steel. THIS WILL NOT BE A LOAD BEARING BUMPER. That is what ii have a trailer hitch for. Nothing will ever be connected to it.

Pictures of brackets

Test fits

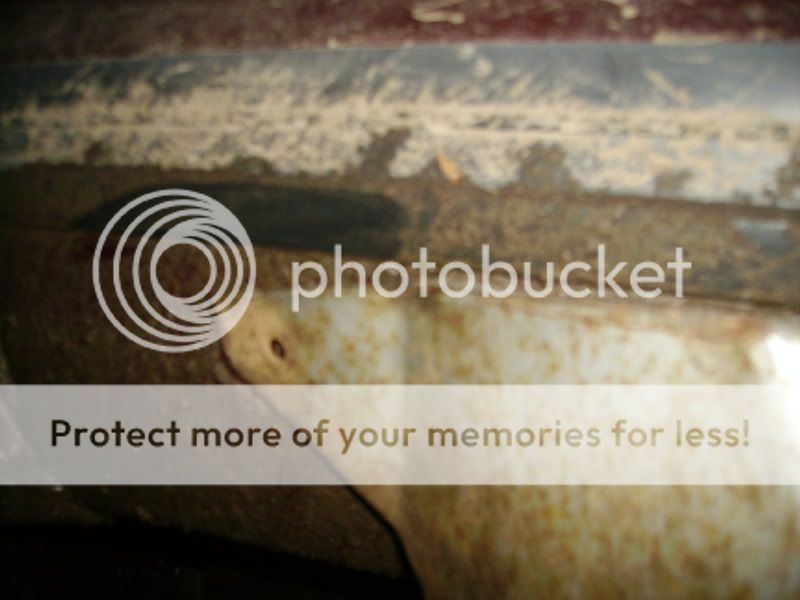

Start to cut. I didn’t think about where I was cutting so I cut a little further in than I wanted. I guess I should have measured. Oh well.

Heres one side cut.

I didn’t take pictures of the other side cut. I took 2.5 inches out of each side.

Well, I decided that I didn't like my old flimsy stock bumper, and I had an old bumper from a hot rod project. I got a welder for Christmas and I was bored, so things clicked. Heres my build.

Heres the bumper. Outside width is 74'' wide, about 10'' wider than the stock MJ bumper. Most of that was the extra metal. The bumper brackets needed to be cut out and replaced. I needed to cut down the bumper a total of 5'' (2.5'' each side) to make it fit. It is made out of 1/8’’ and 3/8’’ plate steel. THIS WILL NOT BE A LOAD BEARING BUMPER. That is what ii have a trailer hitch for. Nothing will ever be connected to it.

Pictures of brackets

Test fits

Start to cut. I didn’t think about where I was cutting so I cut a little further in than I wanted. I guess I should have measured. Oh well.

Heres one side cut.

I didn’t take pictures of the other side cut. I took 2.5 inches out of each side.