' {$STAMP BS2}

'Transmission shifting program for a 1991 Toyota Corolla

speed VAR Byte

lastspeed VAR Byte

performance VAR Bit

overdrive VAR Bit

brakes VAR Bit

tpswot VAR Bit

tpsidle VAR Bit

pulses VAR Word

newpulses VAR Word

pulses=0 'initializes the variable "pulses"

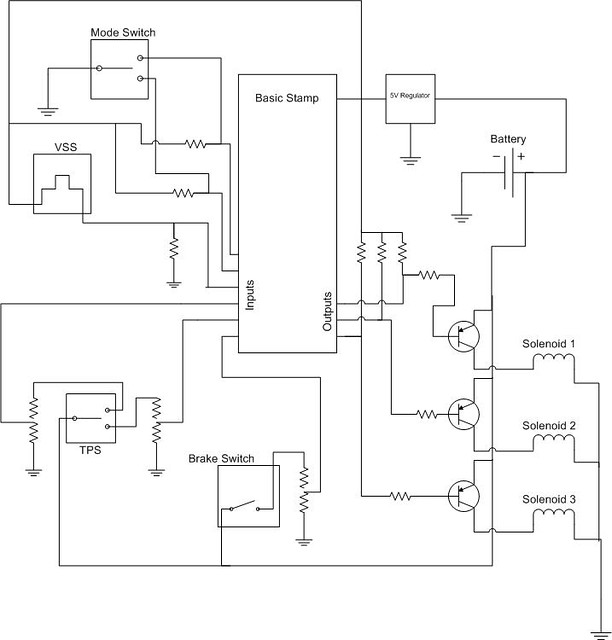

INPUT 0 'speed sensor input

INPUT 1 'performance switch input

INPUT 2 'O/D switch input

INPUT 3 'brake switch input

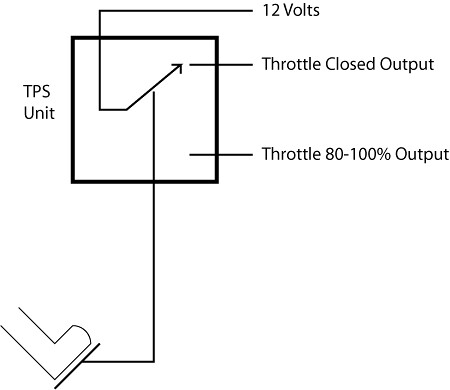

INPUT 4 'TPS WOT input

INPUT 5 'TPS idle input

OUTPUT 8 'output to solenoid 1

OUTPUT 9 'output to solenoid 2

OUTPUT 10 'output to lockup solenoid

mainloop:

performanceswitch:

IF IN1=0 THEN performanceon 'sets status of performance switch to ON

IF IN1=1 THEN performanceoff 'sets status of performance switch to OFF

performanceon:performance=1

GOTO overdriveswitch

performanceoff:performance=0

overdriveswitch:

IF IN2=0 THEN overdriveoff 'sets status of overdrive switch to O/D OFF (down position)

IF IN2=1 THEN overdriveon 'sets status of overdrive switch to O/D ON (up position)

overdriveoff:overdrive=0

GOTO brakestatus

overdriveon:overdrive=1

brakestatus:

IF IN3=0 THEN brakesoff 'sets status of brakes to OFF (brakes not applied)

IF IN3=1 THEN brakeson 'sets status of brakes to ON (brakes applied)

brakesoff:brakes=0

GOTO tpswotstatus

brakeson:brakes=1

tpswotstatus:

IF IN4=0 THEN tpswotoff 'sets status of tpswot to OFF (throttle is not WOT)

IF IN4=1 THEN tpswoton 'sets status of tpswot to ON (throttle is WOT)

tpswotoff:tpswot=0

GOTO tpsidlestatus

tpswoton:tpswot=1

tpsidlestatus:

IF IN5=0 THEN tpsidleoff 'sets status of tpsidle to OFF (throttle is not at idle)

IF IN5=1 THEN tpsidleon 'sets status of tpsidle to ON (throttle is at idle)

tpsidleoff:tpsidle=0

GOTO speedsensing

tpsidleon:tpsidle=1

speedsensing:

COUNT 0, 500, newpulses 'retrieves speed sensor info

pulses=(pulses + newpulses)/2 'averages the count to smooth it out

speed = pulses/2

'IF tpswot=1 THEN accel

'IF tpsidle=1 THEN decel

normal:

'IF lastspeed > speed THEN mainloop 'keeps trasmission from downshifting in normal mode

'lastspeed=speed

'IF performance=0 THEN normalgearselect

'IF performance=1 THEN speedmodify 'modifies speed value if performance switch is on

'speedmodify:

'speed = speed - 5

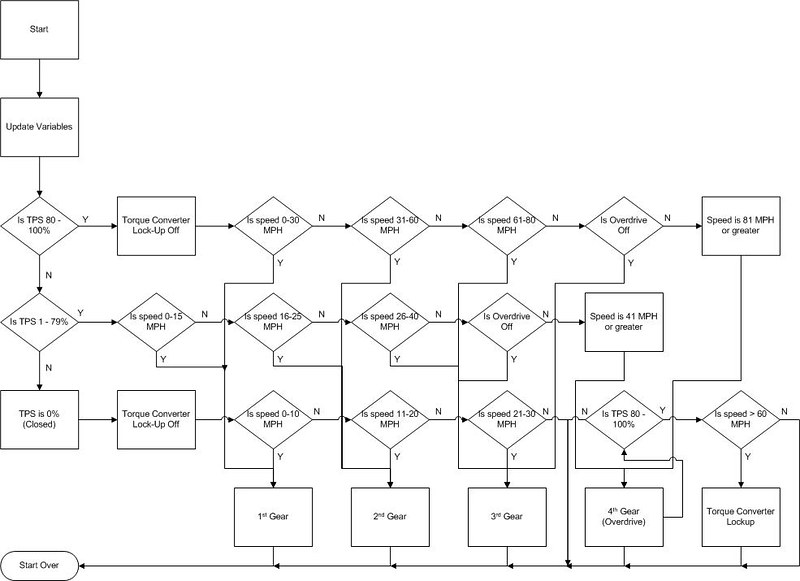

normalgearselect:

IF speed < 15 THEN firstgear

IF speed >=15 AND speed < 25 THEN secondgear

IF speed >=25 AND speed < 40 THEN thirdgear

'IF overdrive = 0 THEN thirdgear

IF speed >= 40 THEN fourthgear

'accel: 'acceleration shift pattern

'IF speed < 30 THEN firstgear

'IF 30 <= speed < 60 THEN secondgear

'IF 60 <= speed < 80 THEN thirdgear

'IF overdrive = 0 THEN thirdgear

'IF speed >= 80 THEN fourthgear

'decel: 'deceleration shift pattern

'LOW 10 'turns off Lock up solenoid

'IF performance=0 THEN normaldecel

'IF performance=1 THEN perfdecel

'normaldecel: 'normal deceleration pattern

'IF speed < 10 THEN firstgear

'GOTO mainloop

'perfdecel: 'performance deceleration pattern

'IF speed < 10 THEN firstgear

'IF 10 <= speed < 20 THEN secondgear

'IF 20 <= speed < 30 THEN thirdgear

'GOTO mainloop

firstgear: 'First gear solenoid activation

HIGH 8

LOW 9

LOW 10

GOTO mainloop

secondgear: 'Second gear solenoid activation

HIGH 8

HIGH 9

LOW 10

GOTO mainloop

thirdgear: 'Third gear solenoid activation

LOW 8

HIGH 9

LOW 10

GOTO mainloop

fourthgear: 'Fourth gear (O/D) solenoid activation

LOW 8

LOW 9

LOW 10

'IF speed < 45 THEN mainloop

'IF speed >= 45 THEN brakeidlecheck

'brakeidlecheck:

'IF brakes=1 THEN mainloop

'IF tpsidle=1 THEN mainloop

'lockup:

'HIGH 10

GOTO mainloop