USAF_XJ

NAXJA Forum User

- Location

- New Mexico

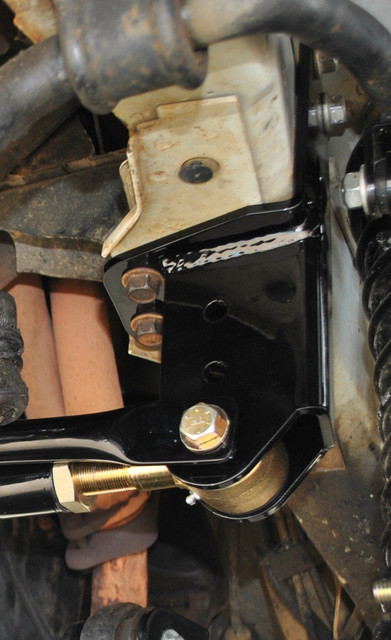

So I installed frame stiffeners to my XJ which meant the stock track bar mounting bolts would no longer line up so I welded the mount to the new frame plates and called it a day. Well after some heavy wheeling the mount has bent and pulled apart the frame in the process. I'm thinking with a BFH I can beat it all back to where its supposed to be and re-weld the frame closed but I was wondering have I done anything wrong with the way I originally welded it? How can I prevent this in the future?