Update!

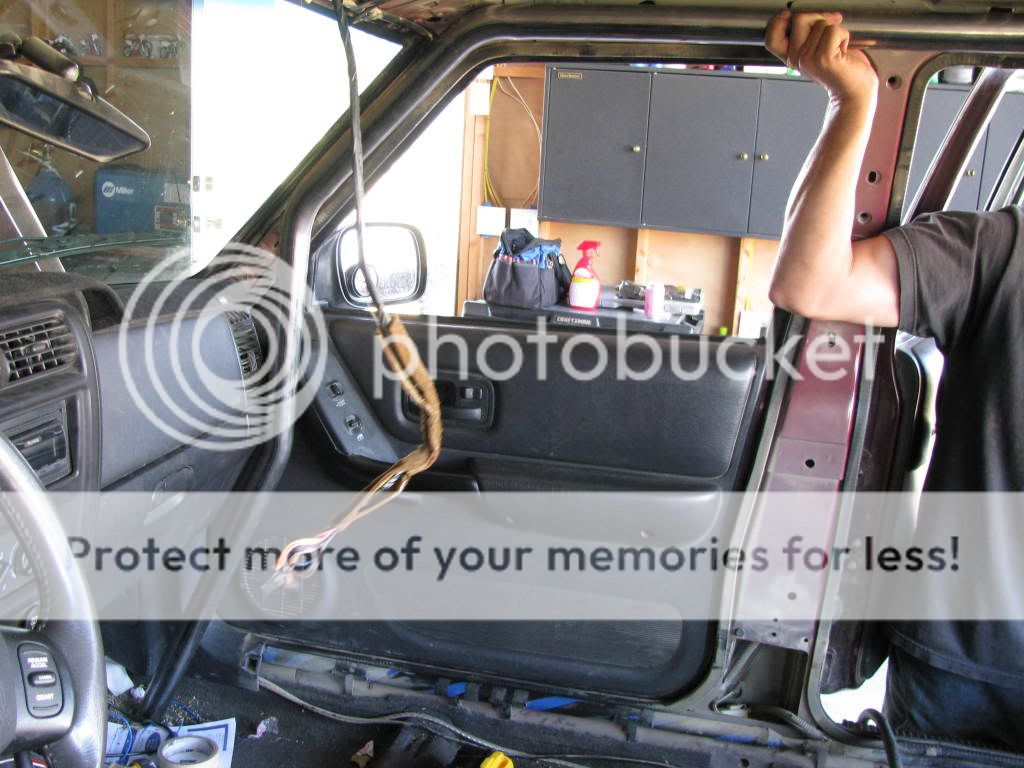

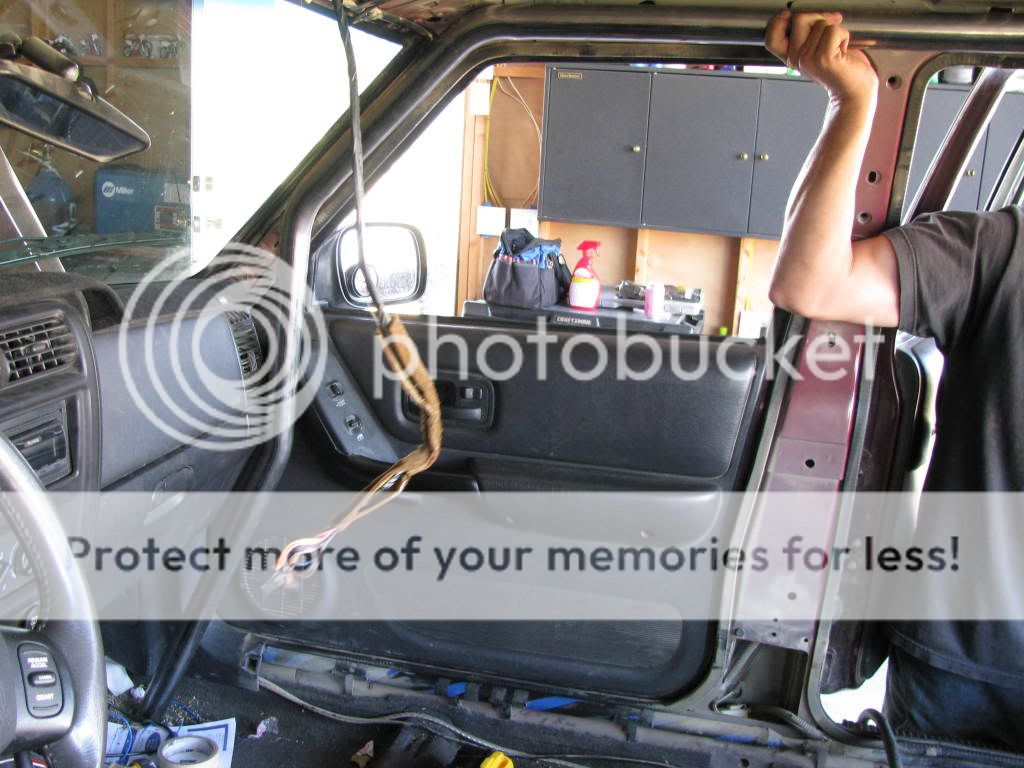

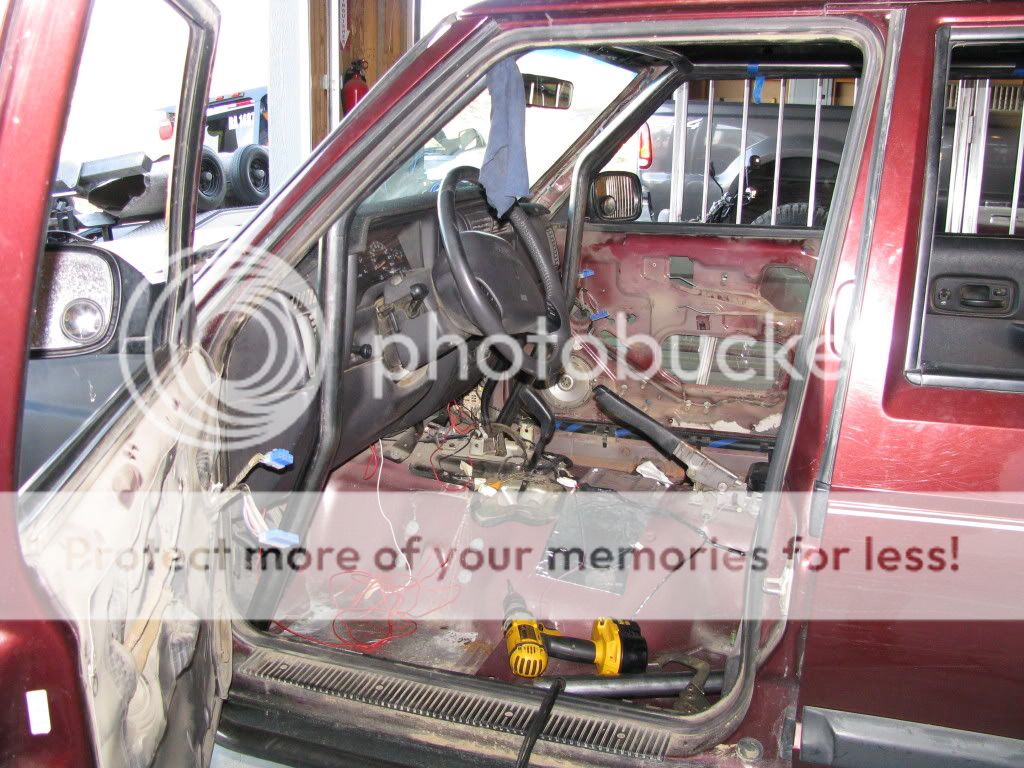

So I found out I had a cracked head today, so it was time to park the Jeep. To put me in a better mood, I used the repo truck and towed it over to my buddy's house and we worked on the cage! We decided to get it to tuck as much as possible, we'll remove all the interior. I'll end up carpeting or using tweed on my roof, and rhino lining the floor. Aluminum door panels are also on the list (oh daaaaaaaaaaan) Here are some pictures of the mock up.

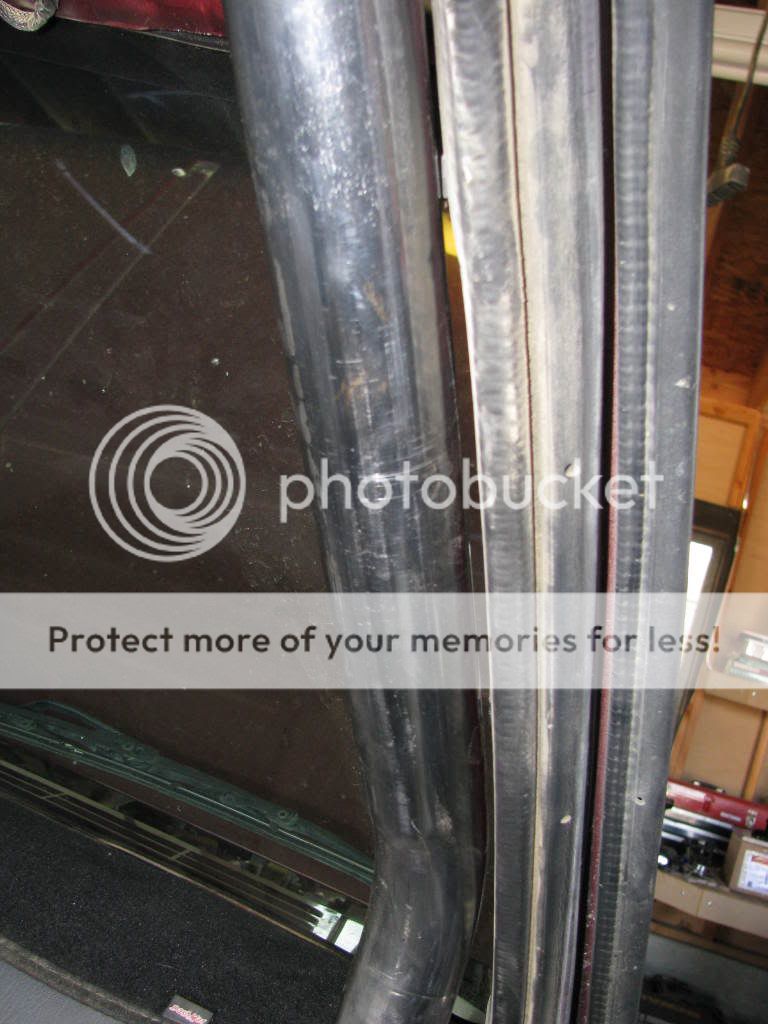

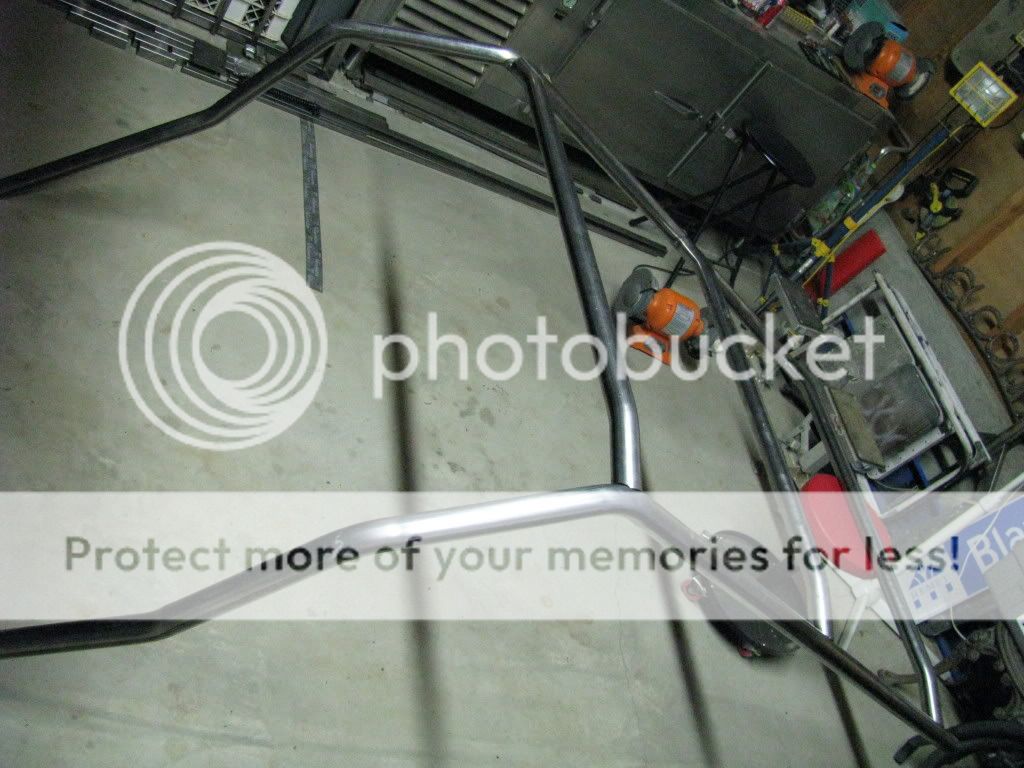

This is Lee's idea of a tack weld :laugh: Good thing we checked it over 50 times before laying a single bead. I swear I adjusted for over an hour to get it perfect before I finally just said eff it let's do it.

We started by slipping the A-pillar bars into the D-pillar bars, and letting them rest, we had to trim about 2 inches or so off, as Tom had already told me the newer style dash takes up more room. We used those ends to raise the back of the cage up higher. We're going to sleeve it later, but they made it perfect for mock up.

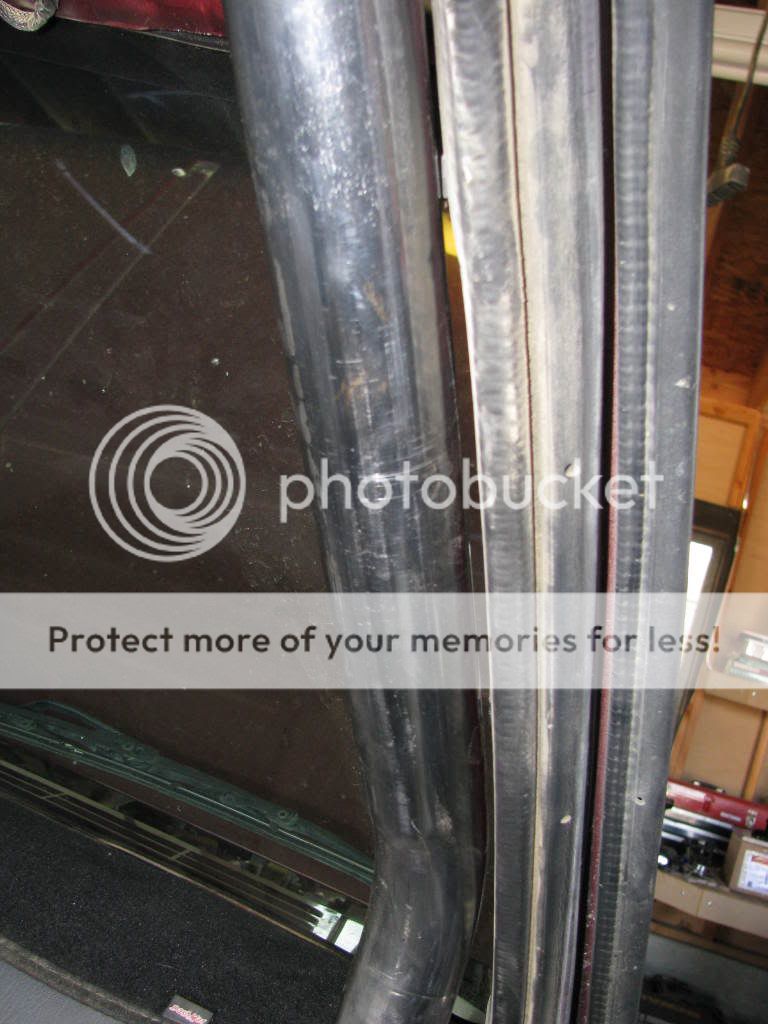

Now... here's the important part. It's VERY important to me to get a good 360 degree weld around all points, this is a huge problem with a lot of cage builders, they just half ass it and leave the top unwelded. If you have a well tucked cage, like this one, it'll be near impossible to weld around IMO. So the bitchin' part is that singe T&J designed these to sleeve into each other, we were able to get the spreader bars all tacked in, then remove the D-pillar and remove the entire front end of the cage. Mind you we don't have any down bars yet, just the spreaders to get full welds. Also keep in mind I have no interior left, you won't be able to do this if you weld it in with a full interior.

Ohhhhh yeaaaa tig welded cage