- Location

- In a strange land

Note that this is not yet a production item. There will probably be some minor revisions to what you see here, but this probably very closely resembles the final design.

When I first bought my XJ I found this site and in reading through interesting threads I found LazyXJ’s hidden winch. That immediately went on my list of mods to eventually accomplish. Then I found Boostwerks’ Ultimate XJ Steering Brace and started trying to figure out how to blend the two ideas. Then in December 2014 the Comp Mount showed up on the Boostwerks website. I have been pestering Bryson ever since. Graciously, rather than getting a restraining order against me, he let me be one of the first guinea pigs to help him work out the final details. I have had this for several weeks now, and while I have not yet finalized my installation I have managed to prove that the Comp Mount fits as it should. There are still some details to be checked (most notably the sway bar) and the weather is interfering with progress, but that same weather is affording me the time to present a bit of a preview. For those who have been waiting, here is what is coming:

Bryson gave me a heads up in the fall that he was getting close to having the pre-production parts ready for me. That gave me time to do some hunting for a deal on a Warn M8000 winch. That is what the design is for. I have a Warn 9000XD, but when I had inquired early on in the process Bryson told me that was an unlikely fit on account of the larger size. Lamentably, no one had any Black Friday deals on an M8000, nor could I find anything leading up to Christmas.

Then Bryson contacted me to say the mount was pretty much ready to ship, and did I want it powder coated or bare? I opted for bare fully expecting I would need to grind and maybe re-weld something. Powder coating isn’t a particularly forgiving finish when it comes to modifications. Bryson also suggested I should go ahead and try the 9000XD as he had made some alterations from the original design and there was a chance the larger winch would fit. Cool.

A couple of days after Christmas the mount arrived. The Varmints were ecstatic to get a large box to play in. Again I ask, why do I spend money on them at Christmas? It could be saved to spend on the Jeep instead. And get more toys like these:

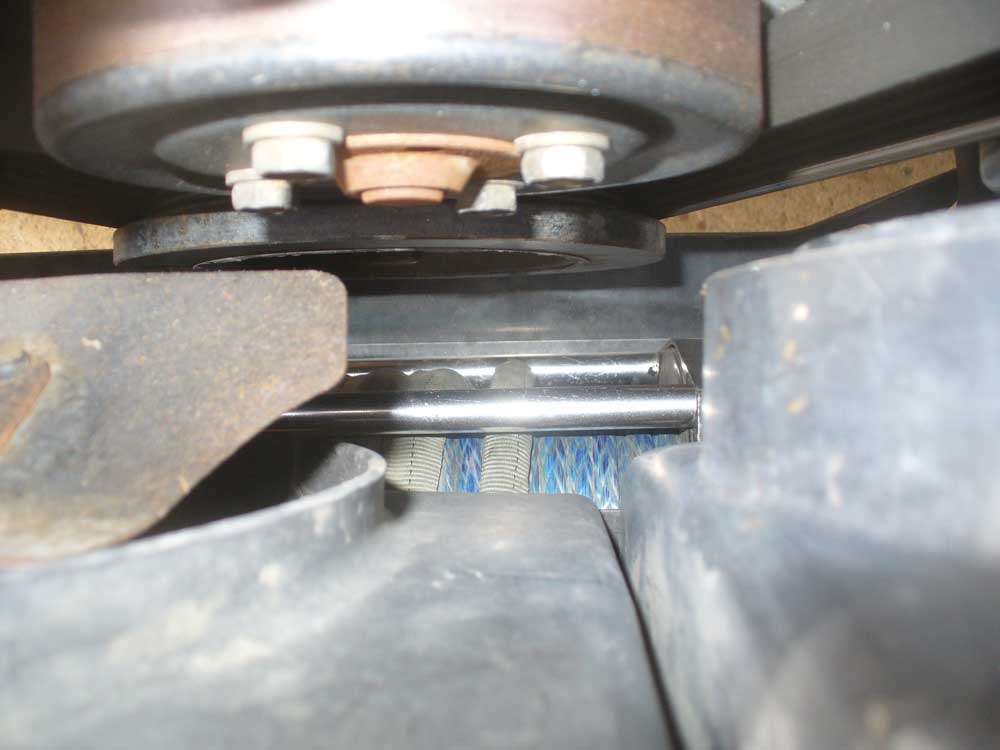

And I pulled out my winch to get a sense of how it would fit in the Comp Mount itself:

It has to be shifted all the way to the right, but it looks like it could fit. Next is to see what kind of interference is offered by the vehicle.

I pulled off the bumper and held the mount up against the radiator support to mark its perimeter with a Sharpie, then took a look at what I thought should be cut out. Because inside corners have a tendency to be stress risers I tried to incorporate as many of the factory holes as I could for the corners of the cuts.

Picture of the marks I made:

Same picture, but with the intended cuts indicated:

The cuts made:

The new opening:

Next, some areas need to be flattened out for the mount to sit flush against the rails. The instructions for the Comp Mount haven’t been written, but Bryson sent me a copy of the instructions for the Ultimate Steering Brace. Those call for flattening the seams with a hammer. I found a hammer would get me two thirds of the way, but the last third would just bounce back. I had better luck finishing it off with a clamp.

On the driver’s side I had a big old glob of weld booger than a previous owner had applied to said seam. That had to be ground down:

And the factory left behind a nice collection of weld boogers on the passenger side. These had to be ground down too:

And I was able to make a first trial fit (note: no winch and no sector shaft support bearing):

That fit told me that I needed to clean up the line of this flange if I wanted to have any hope of fitting my too-large winch in here:

Next step is to mount the winch in the Comp Mount. I knew I needed to rotate the gear box 180 degrees. Warn has a brief note about this very thing right here:

Link: https://www.warn.com/blog/2011/09/2..._winch_end_housing_to_fit_an_arb_bumper.shtml

And because links seem to go dead over time, the text of that reads as follows:

The rotation was made for the sake of progress and new gaskets were ordered so that detail could be revisited properly before the final install.

When I first bought my XJ I found this site and in reading through interesting threads I found LazyXJ’s hidden winch. That immediately went on my list of mods to eventually accomplish. Then I found Boostwerks’ Ultimate XJ Steering Brace and started trying to figure out how to blend the two ideas. Then in December 2014 the Comp Mount showed up on the Boostwerks website. I have been pestering Bryson ever since. Graciously, rather than getting a restraining order against me, he let me be one of the first guinea pigs to help him work out the final details. I have had this for several weeks now, and while I have not yet finalized my installation I have managed to prove that the Comp Mount fits as it should. There are still some details to be checked (most notably the sway bar) and the weather is interfering with progress, but that same weather is affording me the time to present a bit of a preview. For those who have been waiting, here is what is coming:

Bryson gave me a heads up in the fall that he was getting close to having the pre-production parts ready for me. That gave me time to do some hunting for a deal on a Warn M8000 winch. That is what the design is for. I have a Warn 9000XD, but when I had inquired early on in the process Bryson told me that was an unlikely fit on account of the larger size. Lamentably, no one had any Black Friday deals on an M8000, nor could I find anything leading up to Christmas.

Then Bryson contacted me to say the mount was pretty much ready to ship, and did I want it powder coated or bare? I opted for bare fully expecting I would need to grind and maybe re-weld something. Powder coating isn’t a particularly forgiving finish when it comes to modifications. Bryson also suggested I should go ahead and try the 9000XD as he had made some alterations from the original design and there was a chance the larger winch would fit. Cool.

A couple of days after Christmas the mount arrived. The Varmints were ecstatic to get a large box to play in. Again I ask, why do I spend money on them at Christmas? It could be saved to spend on the Jeep instead. And get more toys like these:

And I pulled out my winch to get a sense of how it would fit in the Comp Mount itself:

It has to be shifted all the way to the right, but it looks like it could fit. Next is to see what kind of interference is offered by the vehicle.

I pulled off the bumper and held the mount up against the radiator support to mark its perimeter with a Sharpie, then took a look at what I thought should be cut out. Because inside corners have a tendency to be stress risers I tried to incorporate as many of the factory holes as I could for the corners of the cuts.

Picture of the marks I made:

Same picture, but with the intended cuts indicated:

The cuts made:

The new opening:

Next, some areas need to be flattened out for the mount to sit flush against the rails. The instructions for the Comp Mount haven’t been written, but Bryson sent me a copy of the instructions for the Ultimate Steering Brace. Those call for flattening the seams with a hammer. I found a hammer would get me two thirds of the way, but the last third would just bounce back. I had better luck finishing it off with a clamp.

On the driver’s side I had a big old glob of weld booger than a previous owner had applied to said seam. That had to be ground down:

And the factory left behind a nice collection of weld boogers on the passenger side. These had to be ground down too:

And I was able to make a first trial fit (note: no winch and no sector shaft support bearing):

That fit told me that I needed to clean up the line of this flange if I wanted to have any hope of fitting my too-large winch in here:

Next step is to mount the winch in the Comp Mount. I knew I needed to rotate the gear box 180 degrees. Warn has a brief note about this very thing right here:

Link: https://www.warn.com/blog/2011/09/2..._winch_end_housing_to_fit_an_arb_bumper.shtml

And because links seem to go dead over time, the text of that reads as follows:

What they don’t bother to tell you is that you are likely to need a new gasket if you do this:To make the clutch handle easily accessible, stand the winch up on end

so the housing is straight up in the air. Next, remove the 10 screws

from the end housing then you can lift the winch up about a 1/4" and

rotate it every two holes to the desired position. Reinstall the screws

and you are done.

The rotation was made for the sake of progress and new gaskets were ordered so that detail could be revisited properly before the final install.