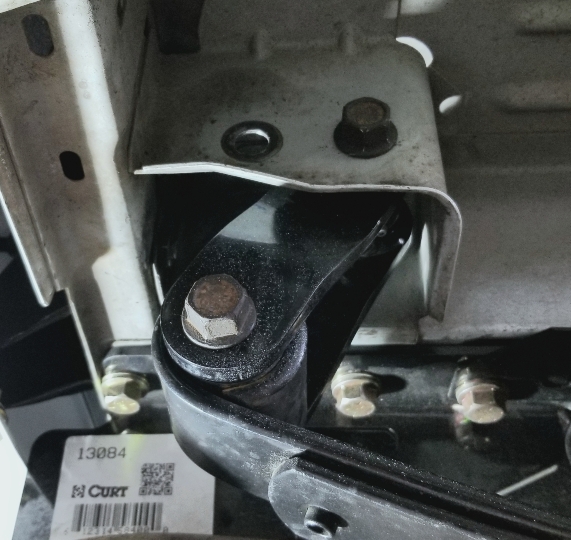

Yep, the shackle is vertical at full spring droop, and on the driver side, the shock reaches full extension about 0.5" of travel before the spring hits full droop. Since the axle shims rotate the axle and create more available shock extension on the passenger side, there is perhaps another 0.75" of extension beyond full spring droop could be forced out of the passenger side, but I still don't think the shackle will hit the box.

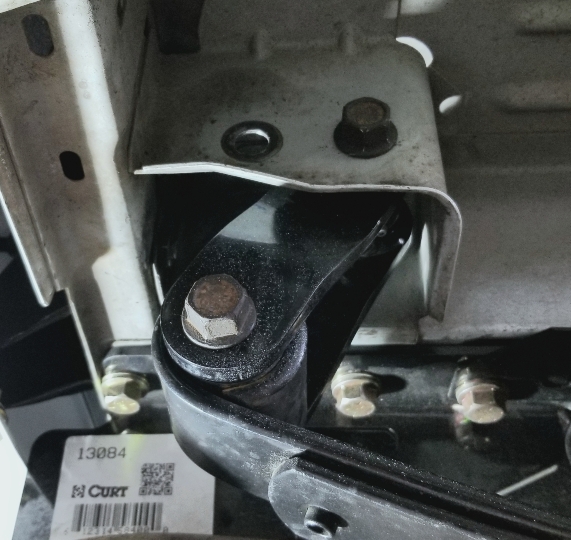

I wrote the wrong relocate distance last night. A 2.0" shift is required to clear the bulge. There's 0.75" of spacer material on the inboard side between the unibody rail and the shackle. This is non-ideal from the perspective of putting some bending moment on the bolt, but I'll take my chances. Also, the unibody rail is double-thick on sheet metal within the shackle box, so there is enough meat to support the bolt especially when comparing to the outboard side that is only single-thick sheet metal. Overall, probably not as tough as an aftermarket shackle box install, but the ease of installation was too good to pass up.