yossarian19

NAXJA Forum User

- Location

- Grass Valley, CA

Since I just spent an hour trying to pin down the info, thought I'd share:

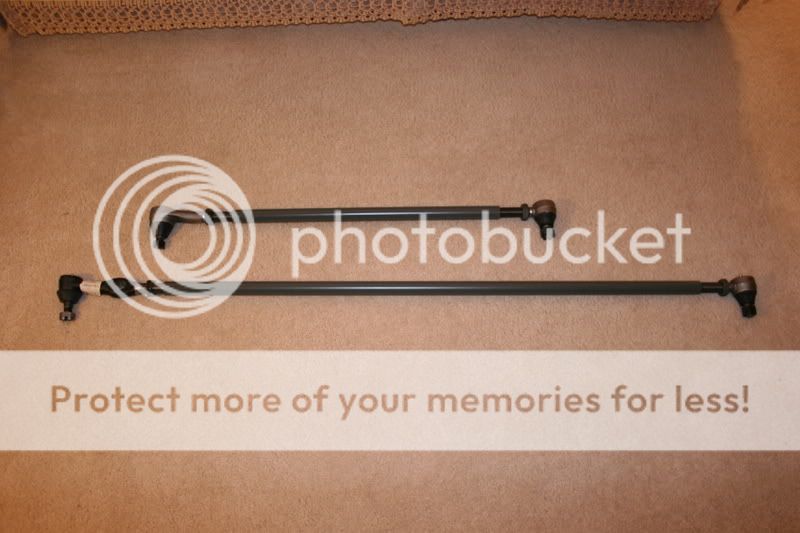

From Knuckle to Knuckle:

Moog ES2233L : Left side

Moog ES2234R : Right side

Drag link, at pitman arm

ES2027L

Drag link, at tie rod (connects to ES2233L)

ES2026R

All four parts are common to the

1981 Chevrolet K10 (half ton, 4wd) pickup truck, though each can be found in a variety of others.

At Rockauto.com they totaled ~100 without tax or shipping. Depending how much DOM tubing & adapters can be had for in your area and how much you are able / willling to fab, this is much cheaper than buying a kit.

They are threaded 7/8" - 18TPR (threads per inch), which you can either bore & tap DOM for or use a weld-in bung for.

Reaming of the knuckles & pitman arm to Chevy taper is required. Chevy Taper is 1.5 inches per foot. On the wide side, the hole should have a 0.7188" diameter.

Amongst others, Synergy Suspension sells a reamer for ~$100 through Quadratec here

With the reamer, TREs, tubing & adapters this should be around a $250 - $300 DIY project, depending on your steel prices. Note that when you buy a kit, be it from Ruffstuff or JCR, you still have to source your own reamer and typically spend $225+ for the other parts. You can have it cheap, fast & right - pick 2.

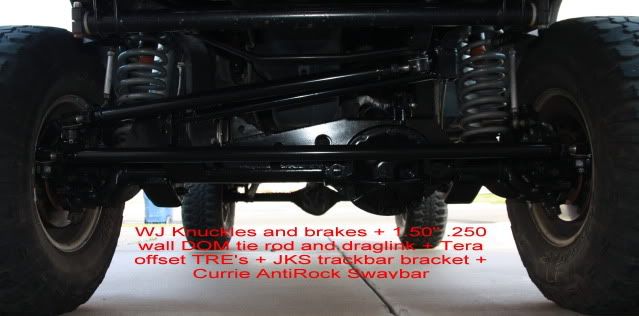

You can run them over or under the knuckle. Best results are probably over the knuckle, both for protection & drag link angle. This setup will require other mods to clear the stock D30 parts.

The parts go together for an "inverted T" steering setup. It is called different things in different places on the internet, but the gist of it is that you have one tie rod from knuckle to knuckle & a drag link that connects the tie rod to the pitman arm.

From Knuckle to Knuckle:

Moog ES2233L : Left side

Moog ES2234R : Right side

Drag link, at pitman arm

ES2027L

Drag link, at tie rod (connects to ES2233L)

ES2026R

All four parts are common to the

1981 Chevrolet K10 (half ton, 4wd) pickup truck, though each can be found in a variety of others.

At Rockauto.com they totaled ~100 without tax or shipping. Depending how much DOM tubing & adapters can be had for in your area and how much you are able / willling to fab, this is much cheaper than buying a kit.

They are threaded 7/8" - 18TPR (threads per inch), which you can either bore & tap DOM for or use a weld-in bung for.

Reaming of the knuckles & pitman arm to Chevy taper is required. Chevy Taper is 1.5 inches per foot. On the wide side, the hole should have a 0.7188" diameter.

Amongst others, Synergy Suspension sells a reamer for ~$100 through Quadratec here

With the reamer, TREs, tubing & adapters this should be around a $250 - $300 DIY project, depending on your steel prices. Note that when you buy a kit, be it from Ruffstuff or JCR, you still have to source your own reamer and typically spend $225+ for the other parts. You can have it cheap, fast & right - pick 2.

You can run them over or under the knuckle. Best results are probably over the knuckle, both for protection & drag link angle. This setup will require other mods to clear the stock D30 parts.

The parts go together for an "inverted T" steering setup. It is called different things in different places on the internet, but the gist of it is that you have one tie rod from knuckle to knuckle & a drag link that connects the tie rod to the pitman arm.

Last edited: