jakbob

NAXJA Forum User

- Location

- Arnold, MD

So, this is my first major thread or anything that resembles a write up. Mind you all of this I did on my 1987 Wagoneer 4.0L AW4 non ABS. I suggest you merely use my technique, not follow this exactly. I cannot factor for all of the variables.

C101 Backstory

The C101 connector is located on the drivers side firewall, above the brake system. The connector is one of those things that are a good idea, but in the end, the execution fell short. After a while, weather gets a hold of it and it starts causing issues with all of the sensors (TPS, IAC, the ground for the MAP, Intake Temp, Etc.) It actually started causing so many problems for the CKP, dealerships bypassed it from the C-101 straight to the the PCM. So rather than pull it off and keep cleaning it, I decided to bypass it all together.

Getting Started

Although I started taking pictures after I pulled the C-101 apart, if you are doing it all at once, you dont have to worry about breaking it.

Before you start cutting every single wire, you need a gameplan. If you end up losing a wire, or miss wiring, it will be a pain fixing it.

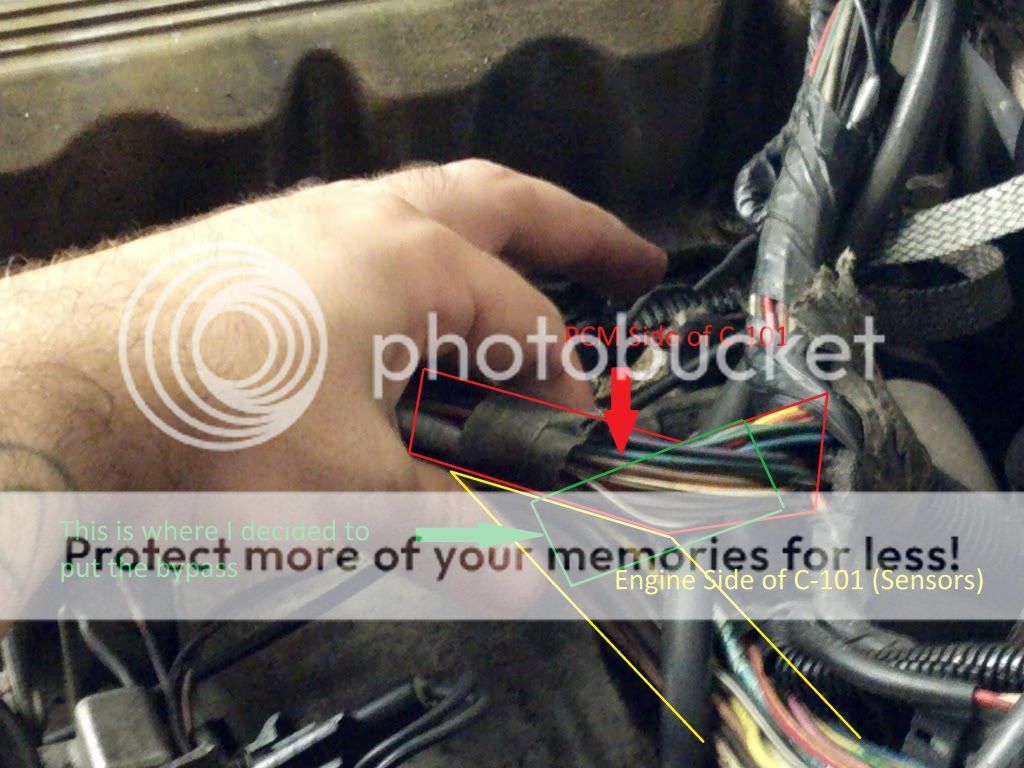

My game plan was to start the bypass where the PCM side of the harness comes out of the firewall.

The wires for the most part are color corresponding, but the best and smartest way to make sure that you dont cross wires, is just do one wire at a time. Trace the wire to the C-101 and find the corresponding wire on the PCM side. Snip and tie together. I tied mine together because I am also cleaning the harness up, getting rid of extra wire so i can keep the wires from resting on the manifold.

Progress Shot, This is snipping one wire at a time mind you.

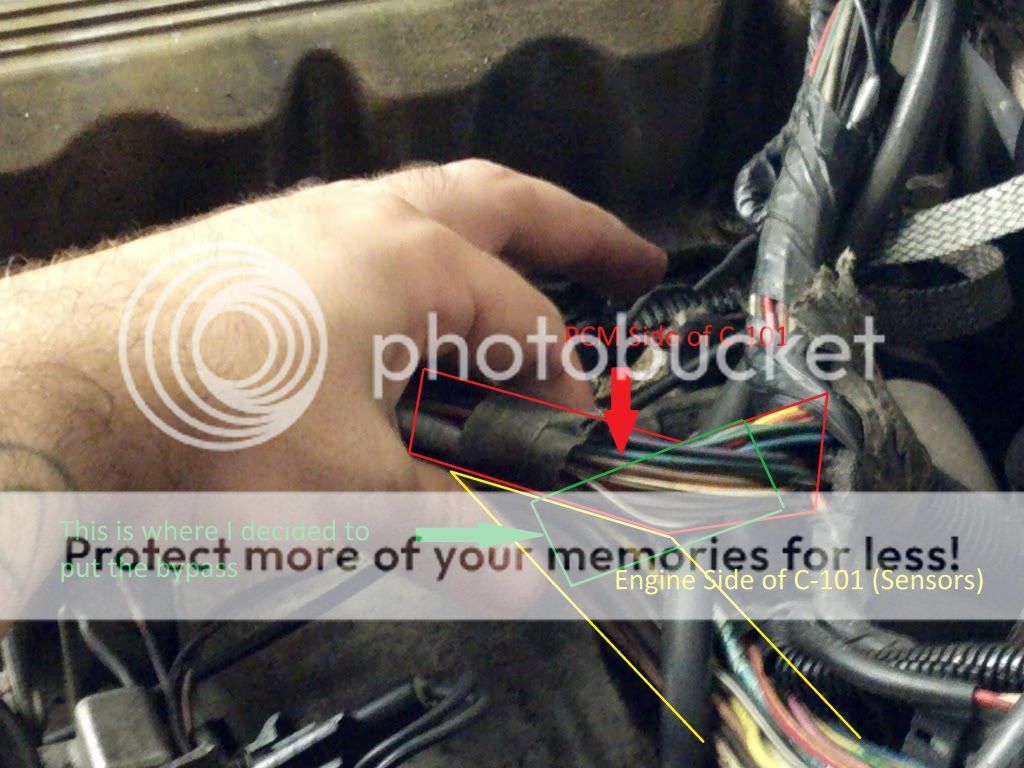

Another progress pic, note that I just tied them because I was also going to shorten the wire up.

If you find duct tape in the harness, do not fret. That is actually from the factory. All of the sensors ground on the same wire. just unwrap the duct tape, and if everything is still shiny, just put some electrical tape back over it. I do however, recommend each sensor run off its own ground, so my plan is later run something similar to a junction box, but a big gauge wire runs straight to the negative battery post. Since this is my DD, I decided to do a little at a time. I didnt do every single wire yet, about 80% done. but once you have everything planned out, either use butt connectors or a soldiering gun and shrink wrap. But remember to be patient. Rushing a wire harness will cause shorts and that "omg my engine is possessed" symptoms. Its definitely not hard, just requires patients. Any questions just PM me. or post here, wherever.

C101 Backstory

The C101 connector is located on the drivers side firewall, above the brake system. The connector is one of those things that are a good idea, but in the end, the execution fell short. After a while, weather gets a hold of it and it starts causing issues with all of the sensors (TPS, IAC, the ground for the MAP, Intake Temp, Etc.) It actually started causing so many problems for the CKP, dealerships bypassed it from the C-101 straight to the the PCM. So rather than pull it off and keep cleaning it, I decided to bypass it all together.

Getting Started

Although I started taking pictures after I pulled the C-101 apart, if you are doing it all at once, you dont have to worry about breaking it.

Before you start cutting every single wire, you need a gameplan. If you end up losing a wire, or miss wiring, it will be a pain fixing it.

My game plan was to start the bypass where the PCM side of the harness comes out of the firewall.

The wires for the most part are color corresponding, but the best and smartest way to make sure that you dont cross wires, is just do one wire at a time. Trace the wire to the C-101 and find the corresponding wire on the PCM side. Snip and tie together. I tied mine together because I am also cleaning the harness up, getting rid of extra wire so i can keep the wires from resting on the manifold.

Progress Shot, This is snipping one wire at a time mind you.

Another progress pic, note that I just tied them because I was also going to shorten the wire up.

If you find duct tape in the harness, do not fret. That is actually from the factory. All of the sensors ground on the same wire. just unwrap the duct tape, and if everything is still shiny, just put some electrical tape back over it. I do however, recommend each sensor run off its own ground, so my plan is later run something similar to a junction box, but a big gauge wire runs straight to the negative battery post. Since this is my DD, I decided to do a little at a time. I didnt do every single wire yet, about 80% done. but once you have everything planned out, either use butt connectors or a soldiering gun and shrink wrap. But remember to be patient. Rushing a wire harness will cause shorts and that "omg my engine is possessed" symptoms. Its definitely not hard, just requires patients. Any questions just PM me. or post here, wherever.