-

Welcome to the new NAXJA Forum! If your password does not work, please use "Forgot your password?" link on the log-in page. Please feel free to reach out to [email protected] if we can provide any assistance.

- Home

- Forums

- NAXJA Unibody Jeep Technical Forums

- Jeep Cherokee XJ (1984 - 2001)

- Modified Tech Discussion

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

My jeep build with photos over the last few years.

- Thread starter Evan03

- Start date

- Location

- Colorado

Ive seen shovels used as land anchors... Would probably have to bury that lil guy to the hilt... Even then I doubt itd provide enough resistance to pull from.

- Location

- NJ, U.S.A.

I've heard of burying a tire to use as an anchor...

I wish I had a spare.

I think I've got stuff to hack together a pull pal.

Broke a u joint.

https://youtu.be/3N5A-g36jN0

Sent from my SM-G960U using Tapatalk

I think I've got stuff to hack together a pull pal.

Broke a u joint.

https://youtu.be/3N5A-g36jN0

Sent from my SM-G960U using Tapatalk

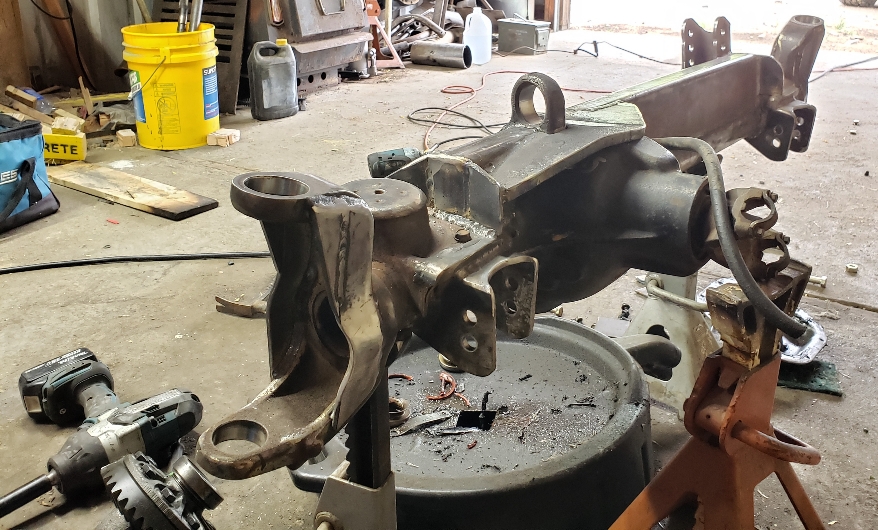

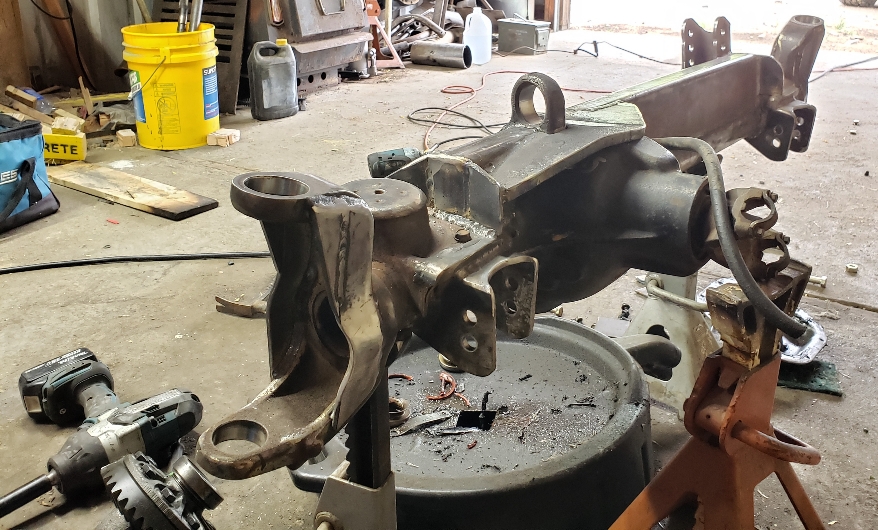

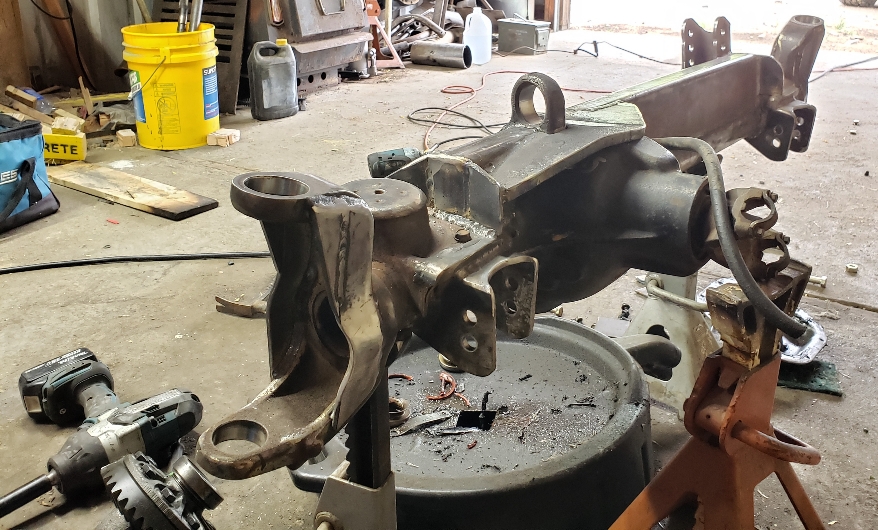

Alittle motivation tonight. Ofcourse I ran out of wire as soon as I was going to tack n track bracket and figure out how truss is going to graft into it.

Not entirely sure how I'm going to truss short side. Almost think it's not even worth messing with.

C gussets are a huge pain in the ass but I guess worthwhile since I'm doing it.

Really looking forward to glueing truss to center. I may run some magic rod made for dissimilar materials offcourse pre and post heat.

Had some 9/16 ubolts bent for the the 8.25 today

Bed time.

Sent from my SM-G960U using Tapatalk

Not entirely sure how I'm going to truss short side. Almost think it's not even worth messing with.

C gussets are a huge pain in the ass but I guess worthwhile since I'm doing it.

Really looking forward to glueing truss to center. I may run some magic rod made for dissimilar materials offcourse pre and post heat.

Had some 9/16 ubolts bent for the the 8.25 today

Bed time.

Sent from my SM-G960U using Tapatalk

Question guys.

My track bar mounts in the middle hole. Top of truss will be welded through lower hole. Should I make it so I have access to lower later on?

I'm going to Barry track bar bracket in the truss. I'm messing around with a gusset tied into it. Should I make it bigger? Maybe run the gusset half way down the truss or so.

Nothing is burned in yet. Need wait till daylight to make sure track bracket is on correctly to match other axle.

Thanks guys for the ideas.

Sent from my SM-G960U using Tapatalk

My track bar mounts in the middle hole. Top of truss will be welded through lower hole. Should I make it so I have access to lower later on?

I'm going to Barry track bar bracket in the truss. I'm messing around with a gusset tied into it. Should I make it bigger? Maybe run the gusset half way down the truss or so.

Nothing is burned in yet. Need wait till daylight to make sure track bracket is on correctly to match other axle.

Thanks guys for the ideas.

Sent from my SM-G960U using Tapatalk

- Location

- Colorado

Add an upper and you got a nice 3 link there... non adjustable just means you need to get the body side mounts spot on... I’d def make the upper adjustable so you can dial in pinion angle tho

- Location

- Northern California

Question guys.

My track bar mounts in the middle hole. Top of truss will be welded through lower hole. Should I make it so I have access to lower later on?

I'm going to Barry track bar bracket in the truss. I'm messing around with a gusset tied into it. Should I make it bigger? Maybe run the gusset half way down the truss or so.

Nothing is burned in yet. Need wait till daylight to make sure track bracket is on correctly to match other axle.

Thanks guys for the ideas.

Sent from my SM-G960U using Tapatalk

Man, that’s gonna be a beefy D30 when you’re done! Have you thought about turning your C’s to get better castor since you’re in a good spot to do it?

Sent from my iPhone using Tapatalk

Doc I have thought about turning the C's but dont know that its neccessary in my application being I'm 2" minus lift.

Thanks. Its heavy that's for sure

I have some flat top dana44/10bolt knuckles.

I think Dana 30 and 44 share the same balljoints. They also share inner axle ujoints.

So I was contemplating dana 44 knuckles dana 44 stubs to dana30 inner shafts. This could potentially be a 8 lug 30 with real live locking hubs. I haven't researched or attempted putting parts together but I do have the complete Dana 44 8 lug chevy front axle

Just noticing the common parts they share.

Shooter.

The gladiator arms have one problem the bushings use a 5/8" bolt wtf Chrysler.

I dont want to drill out my brackets because I want to stay with 9/16 bolts

I am thinking 3 link and starting to eye the truss side of the axle.

I have the parts jeep up on jack stands have a fair amount of time crawling under it measuring.

Driver side upper need to have factory still end welded on at slight angle to find a path to the bracket. And clear driveline and exhaust.

For some reason I have it in my head that i think its better to run on the driveline side something to do with the driveline. Not sure though. 3 link. Looking at it I honestly cant see why it would matter wich side the upper is on.

I got tired of my v8 sounding jeep so welded the old muffler that came off my welder on the jeep. It mellowed out the sound alot but man my rear end is howling like crazy. It's so loud.

Picture is because I didnt take any pictures last trip out. This is a sheep herders water truck. It wasn't here a week ago they took the keys out and plates off it. Hmm. Made for a cool picture. I was eyeing the trans with pto.

Sent from my SM-G960U using Tapatalk

Thanks. Its heavy that's for sure

I have some flat top dana44/10bolt knuckles.

I think Dana 30 and 44 share the same balljoints. They also share inner axle ujoints.

So I was contemplating dana 44 knuckles dana 44 stubs to dana30 inner shafts. This could potentially be a 8 lug 30 with real live locking hubs. I haven't researched or attempted putting parts together but I do have the complete Dana 44 8 lug chevy front axle

Just noticing the common parts they share.

Shooter.

The gladiator arms have one problem the bushings use a 5/8" bolt wtf Chrysler.

I dont want to drill out my brackets because I want to stay with 9/16 bolts

I am thinking 3 link and starting to eye the truss side of the axle.

I have the parts jeep up on jack stands have a fair amount of time crawling under it measuring.

Driver side upper need to have factory still end welded on at slight angle to find a path to the bracket. And clear driveline and exhaust.

For some reason I have it in my head that i think its better to run on the driveline side something to do with the driveline. Not sure though. 3 link. Looking at it I honestly cant see why it would matter wich side the upper is on.

I got tired of my v8 sounding jeep so welded the old muffler that came off my welder on the jeep. It mellowed out the sound alot but man my rear end is howling like crazy. It's so loud.

Picture is because I didnt take any pictures last trip out. This is a sheep herders water truck. It wasn't here a week ago they took the keys out and plates off it. Hmm. Made for a cool picture. I was eyeing the trans with pto.

Sent from my SM-G960U using Tapatalk

Ok back to parts jeep. Layed it n its side. Much much easier to work on

Theres a 231 in my jeep this has a 231 and I have a 242 out of the first parts jeep.

Was kinda looking into lower gears for the 231s but that's kinda spendy like 800.

https://youtu.be/5Ev_1G1tfT0

No broken glass on this lay over

Sent from my SM-G960U using Tapatalk

Theres a 231 in my jeep this has a 231 and I have a 242 out of the first parts jeep.

Was kinda looking into lower gears for the 231s but that's kinda spendy like 800.

https://youtu.be/5Ev_1G1tfT0

No broken glass on this lay over

Sent from my SM-G960U using Tapatalk

- Location

- Colorado

You can get some tube inserts to convert the 5/8 to 9/16.. Pretty cheap to biy a stick and cut what ya need. I was originally going to do that on my lower CAs but decided to drill out for 5/8s due to beef factor and bent stockers i had to cut out

I think I decided on poly bushing on axle and 1.25 heims on frame. I have everything but heims. Also have the 2"x.25 square tube.

I cut down 3 " poly bushings to fit 2 5/8"

It's a busy place around here not doing any jeep stuff this weekend.

Sent from my SM-G960U using Tapatalk

I cut down 3 " poly bushings to fit 2 5/8"

It's a busy place around here not doing any jeep stuff this weekend.

Sent from my SM-G960U using Tapatalk

Only thing left to do is shock mounts . No more I've polished it all I can and wasted time and materials.

That's 1/2" tieing both sides together.

Putting in seals then do brake lines on 8.25 just bought a double flaring set guess I'll learn how to build lines.

Sent from my SM-G960U using Tapatalk

That's 1/2" tieing both sides together.

Putting in seals then do brake lines on 8.25 just bought a double flaring set guess I'll learn how to build lines.

Sent from my SM-G960U using Tapatalk

- Location

- Northern California

Only thing left to do is shock mounts . No more I've polished it all I can and wasted time and materials.

That's 1/2" tieing both sides together.

Putting in seals then do brake lines on 8.25 just bought a double flaring set guess I'll learn how to build lines.

Sent from my SM-G960U using Tapatalk

That’s pretty beefy man

Sent from my iPhone using Tapatalk

- Location

- Colorado

Solid.

I just pulled the rear and found broken leafs on each side.. yay

I just pulled the rear and found broken leafs on each side.. yay

- Location

- Colorado

Tuned in to see shock mount ideas.. wish I would’ve thought about changing them with the axle out smmfh

Time to rotate things like tires axles and transmission .

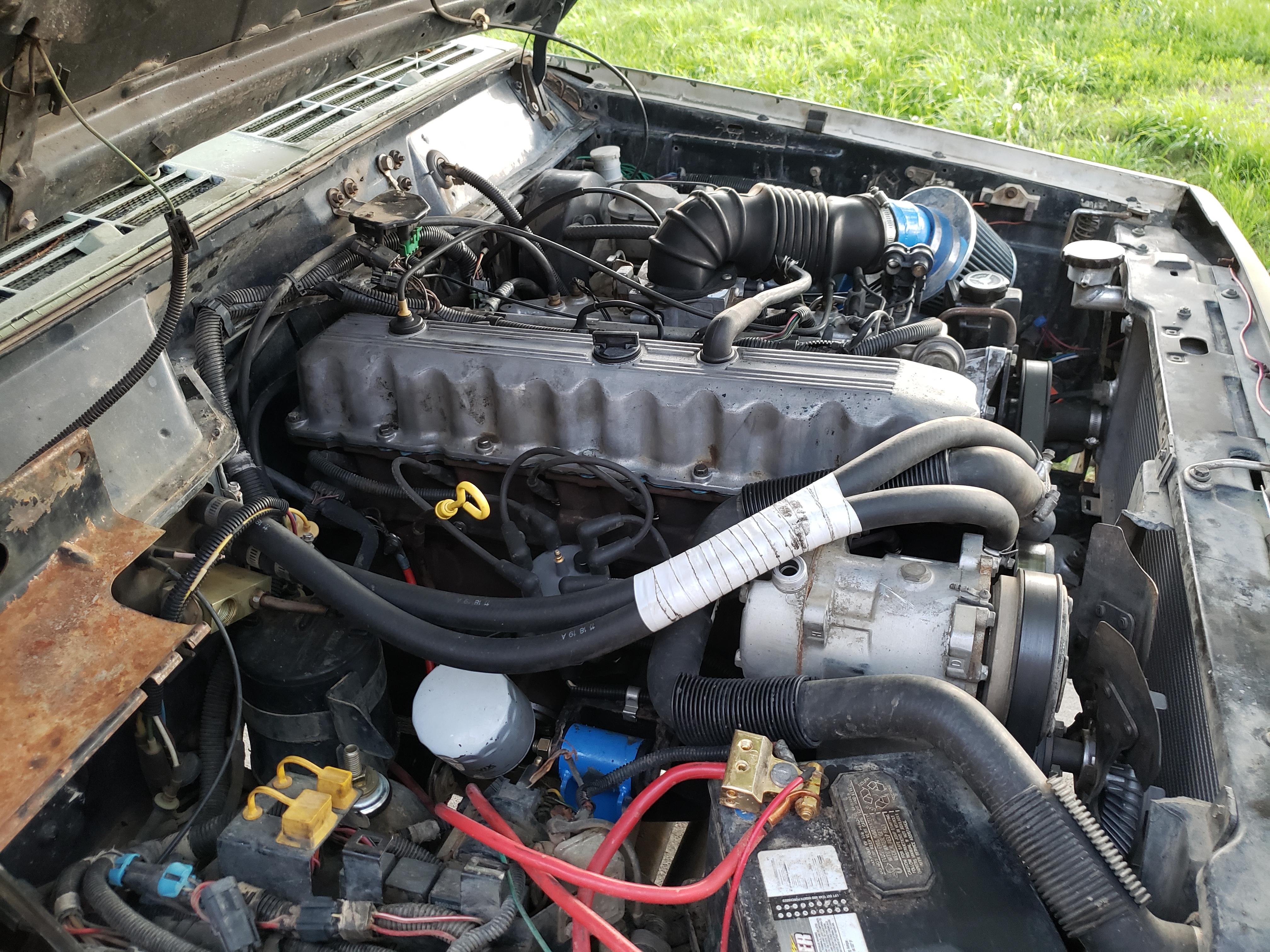

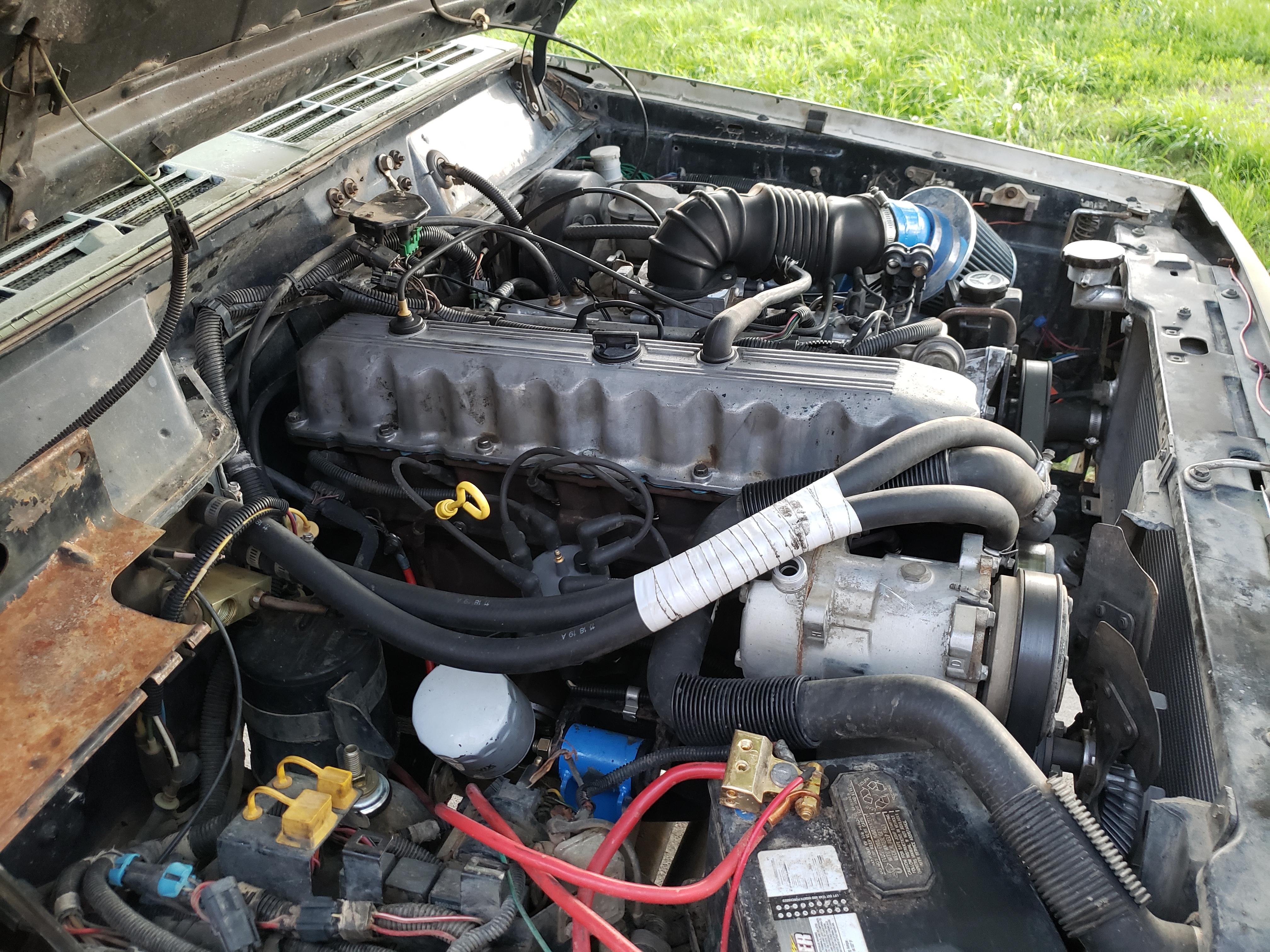

Been dragging my feet on a few things. Replaced injectors with 4hole injectors replaced leaking fuel rail. Replaced oil pressure sending unit. I've had no pressure reading the 5 years I've had the cheap though I knew it had pressure since it keeps running.

Mdid a full tune up its lwys ran good enough but runs better now. Plug wires I didnt want to build opened the dang box and well I guess I had to. Since I had the crimper already wires were supposed to be just OEM replacement. Offcourse they weren't they were for a v-8 .have enough to make a set for my welder to.

Figured on the back patio concrete will work so I dont tie up my garage shell be a few day project.

Pretty cool sunset turned into a lighting storm

Sent from my SM-G960U using Tapatalk

Been dragging my feet on a few things. Replaced injectors with 4hole injectors replaced leaking fuel rail. Replaced oil pressure sending unit. I've had no pressure reading the 5 years I've had the cheap though I knew it had pressure since it keeps running.

Mdid a full tune up its lwys ran good enough but runs better now. Plug wires I didnt want to build opened the dang box and well I guess I had to. Since I had the crimper already wires were supposed to be just OEM replacement. Offcourse they weren't they were for a v-8 .have enough to make a set for my welder to.

Figured on the back patio concrete will work so I dont tie up my garage shell be a few day project.

Pretty cool sunset turned into a lighting storm

Sent from my SM-G960U using Tapatalk

- Location

- In a strange land

Awesome sunset.

I have a complete 10bolt with flat top knuckle I machined myself yes correctly I've known it at least think I know that dana30 and 44/10blt share C's

Is it worth toying with the idea of running the flat top knuckes to gain locking hubs.

Running 8lug wheels on the front for me wouldn't be a deal breaker. I could run cheap 17x8 dodge wheels with 2.5" wide spacers on the rear to go 8lug on the 8.25 axle.

By measuring the dana 30 will get roughly 6" wider overall with the d44 flat top knuckles with everything Chevy outside the knuckle.

3" does put me flying crap outside my fenders alittle bit.

I'm just thinking outloud probly wont do it because I'm broke and would have to source inner axle shafts and who knows what else ounce I actually made the decision to attempt it.

Sent from my SM-G960U using Tapatalk

Is it worth toying with the idea of running the flat top knuckes to gain locking hubs.

Running 8lug wheels on the front for me wouldn't be a deal breaker. I could run cheap 17x8 dodge wheels with 2.5" wide spacers on the rear to go 8lug on the 8.25 axle.

By measuring the dana 30 will get roughly 6" wider overall with the d44 flat top knuckles with everything Chevy outside the knuckle.

3" does put me flying crap outside my fenders alittle bit.

I'm just thinking outloud probly wont do it because I'm broke and would have to source inner axle shafts and who knows what else ounce I actually made the decision to attempt it.

Sent from my SM-G960U using Tapatalk

Similar threads

- Replies

- 1

- Views

- 275

- Replies

- 65

- Views

- 17K

- Replies

- 16

- Views

- 6K

- Replies

- 6

- Views

- 2K