Guys I installed a sye kit on my xj and I used the front driveshaft for the rear to be able to drive it. But now I have vibration. Is that normal? I thought the front driveshaft was balanced? I’m going to have a to get another driveshaft here soon. Just curious why I’m getting vibration.

-

Welcome to the new NAXJA Forum! If your password does not work, please use "Forgot your password?" link on the log-in page. Please feel free to reach out to [email protected] if we can provide any assistance.

- Home

- Forums

- NAXJA Unibody Jeep Technical Forums

- Jeep Cherokee XJ (1984 - 2001)

- Modified Tech Discussion

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Xj sye kit

- Thread starter Bmfinney

- Start date

- Location

- In a strange land

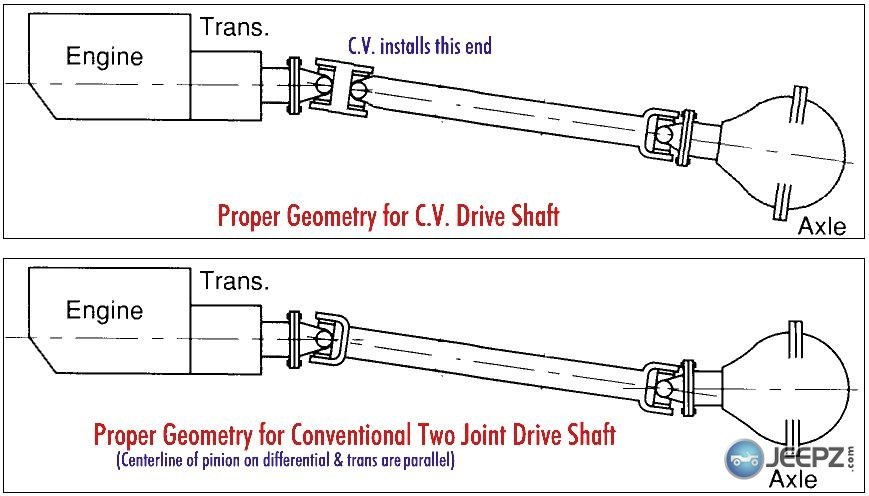

What is your pinion angle?

Did you shim the rear?

If these questions are new to you there is a difference in required pinion angle when you go with a double cardan driveshaft. Tom Woods' site has information on it. Or you can Google it.

That is the first issue that comes to mind for me. If you have all that properly covered I would then question whether that front driveshaft is indeed properly balanced. It may have been balanced originally, but it is possible it is no longer in balance. A good driveline shop should be able to check it for you.

I will also note that centering balls often get overlooked in maintenance. When they fail they can take the T-case out at the same time. Asking a centering ball to get used to life in a new range of motion may not work out for you.

Did you shim the rear?

If these questions are new to you there is a difference in required pinion angle when you go with a double cardan driveshaft. Tom Woods' site has information on it. Or you can Google it.

That is the first issue that comes to mind for me. If you have all that properly covered I would then question whether that front driveshaft is indeed properly balanced. It may have been balanced originally, but it is possible it is no longer in balance. A good driveline shop should be able to check it for you.

I will also note that centering balls often get overlooked in maintenance. When they fail they can take the T-case out at the same time. Asking a centering ball to get used to life in a new range of motion may not work out for you.

RCP Phx

NAXJA Forum User

- Location

- Phoenix,Az

X2 on everything Anak said......

RCP Phx

NAXJA Forum User

- Location

- Phoenix,Az

BTW, what year and was it a HD SYE kit?

It’s pretty much a stock xj I think it has a small lift maybe a 2” lift. Only reason I put it on was cause I had to rebuild the transfer case. Figured I’d make it stronger it’s not the heavy duty kit. I did install a 6 pinion planetary inside it. But the kit didn’t come with a 1.5” chain. When I get to about 50 mph it has a wobble now that wasn’t there I jacked up the rear end to see what it does when I get it up to speed and you can see a big vibration at the back of he vehicle.

RCP Phx

NAXJA Forum User

- Location

- Phoenix,Az

The lift didn't cause the problem, the fact that you changed the design did! A H-n-T is not the best solution vs a HD sye. The wide chain set is separate deal than the planetaries so it's not a factor either you just need to shim the axle!

To use the front driveshaft, you need a 4.5" lift or more. That is also dependent on what axle you use. The driveshaft needs to slip forward 1" and 2-3" to the rear.

I did a HnT on a '98 XJ with a 4.5" lift and a 8-1/4 rear. I cut the TC splines to the min. of 1-1/8". It barely fit. The rear springs were Rough Country. They were probably 6-1/2 at the initial install. After 3 years they did come down to 4.5". During that time I had a Ford 8.8 installed. I did not check the slip length. I was getting some weird actions from the rear end at times. Sort a Death Wobble from the rear. I am in the process of transferring parts from that XJ, for another XJ build. I found that the slip was about 3/8 or so. I did put in an 8-1/4 back in. The slip was around 1".

I did a HnT on a '98 XJ with a 4.5" lift and a 8-1/4 rear. I cut the TC splines to the min. of 1-1/8". It barely fit. The rear springs were Rough Country. They were probably 6-1/2 at the initial install. After 3 years they did come down to 4.5". During that time I had a Ford 8.8 installed. I did not check the slip length. I was getting some weird actions from the rear end at times. Sort a Death Wobble from the rear. I am in the process of transferring parts from that XJ, for another XJ build. I found that the slip was about 3/8 or so. I did put in an 8-1/4 back in. The slip was around 1".

- Location

- In a strange land

It looks like there are two ways you can go. One is to shim the rear to get the correct pinion angle for a double cardan driveshaft. The other is to have a conventional driveshaft built for use with a flanged T-case output (I am assuming such a thing can be built--I cannot recall having seen one, but I expect it is feasible. A good driveline shop should be able to advise you.)

If you go the shim route, keep in mind you will need to replace the U-bolts for your leaf springs. Those are supposed to be replaced each time they are removed. However, since shimming the rear may be a bit of trial and error you may want to hold off the installation of the new U-bolts until you get the angle dialed in. IOW, use your old U-bolts for setup purposes until you are confident you have your final geometry nailed.

If you go the shim route, keep in mind you will need to replace the U-bolts for your leaf springs. Those are supposed to be replaced each time they are removed. However, since shimming the rear may be a bit of trial and error you may want to hold off the installation of the new U-bolts until you get the angle dialed in. IOW, use your old U-bolts for setup purposes until you are confident you have your final geometry nailed.

RCP Phx

NAXJA Forum User

- Location

- Phoenix,Az

What does A H&T stand for?

Hack and Tap!

RCP Phx

NAXJA Forum User

- Location

- Phoenix,Az

Better re-check with some accurate numbers, there is no way without a massive transfer case drop that you should be at 7* down. Are you measuring with the Jeep parked on a perfectly flat surface?

Similar threads

- Replies

- 5

- Views

- 1K