JEONLYEP

NAXJA Forum User

- Location

- N 37° 48.485 W 100° 20.903

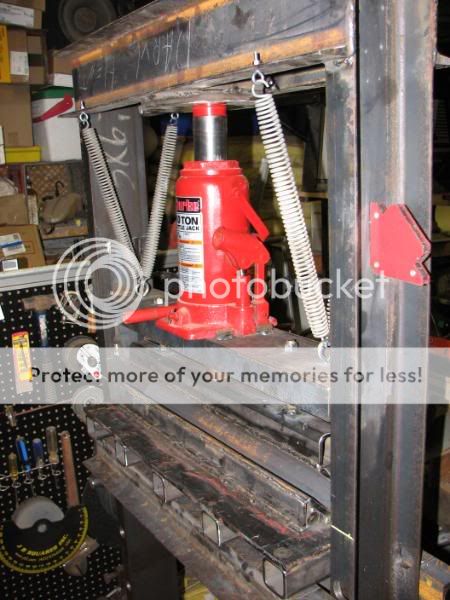

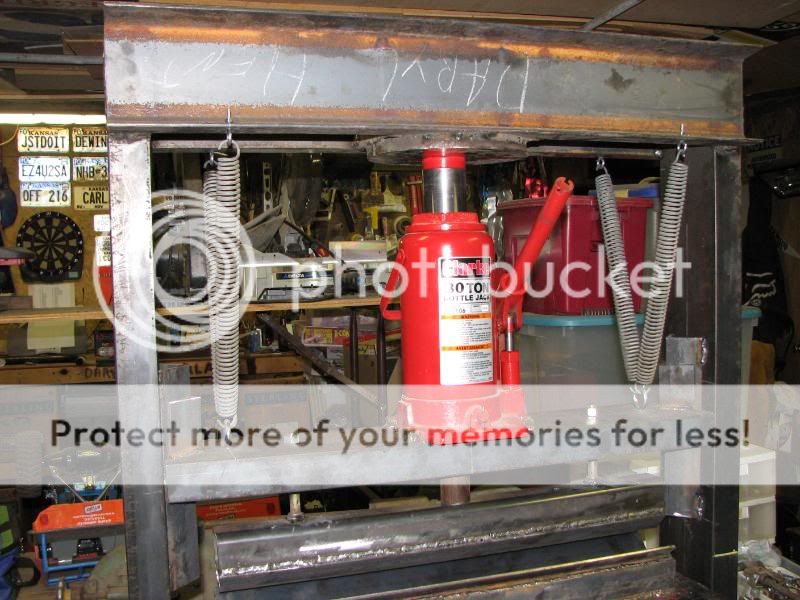

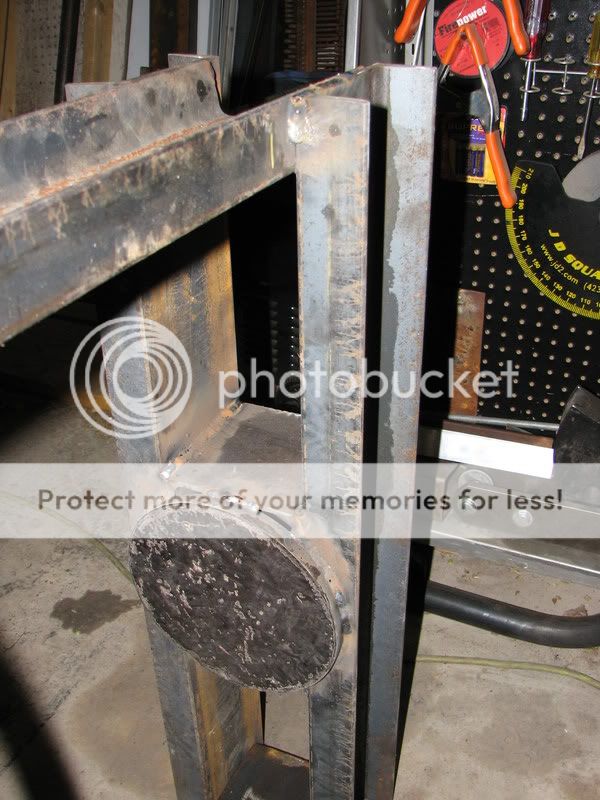

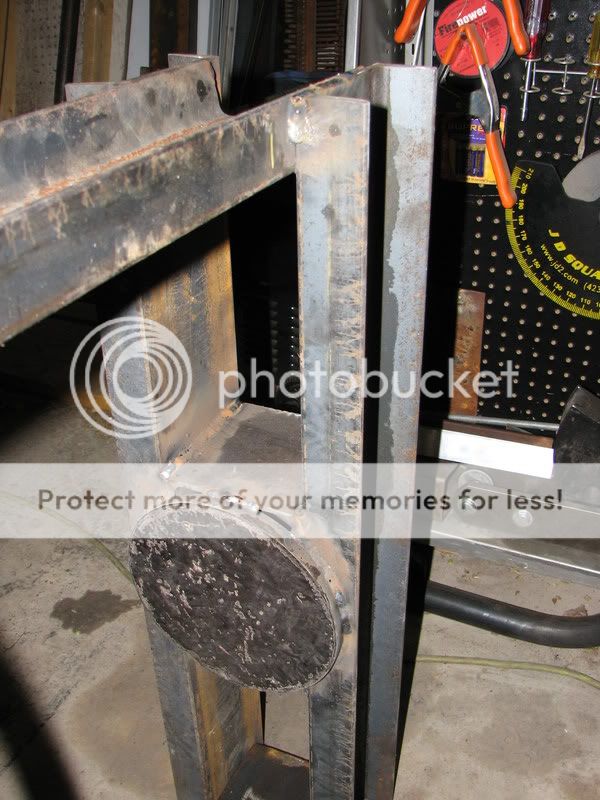

So.... I am making my own.... Was doing fine, until I ran out of wire....

That is all.....

That is all.....

Last edited: