So this one should make everyone think.

Have a D30 with 4.56s a stock drive shaft and a nvg241or.

In 4wheel everything works as it should.

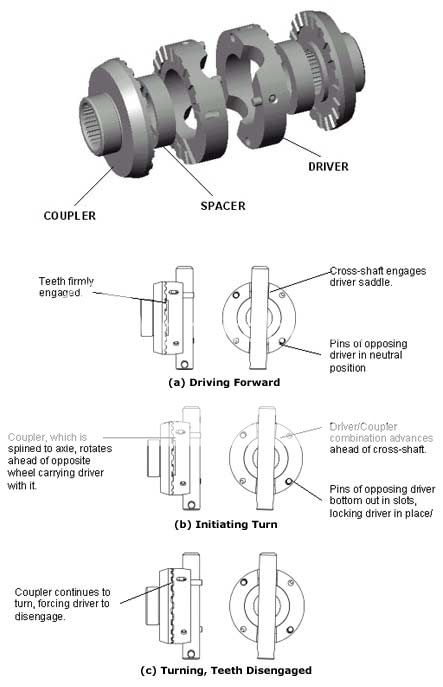

But in 2wheel turning 90* and a little less the front wants to engage and really bucks the front end. If i pull the front shaft all this stops and the locker acts like it should in 2wheel. No feeling and sometimes hearing it click. The drive shaft joints are nice and free and so is the center ball. The tcase is really in 2wheel and i have no rotation when up on stands. The pinion drag is fine and well within spec. The carrier speced out great with the locker installed and i have checked it twice after the frist install.

Its almost like the spring in the locker are to stiff and the drag from the driveshaft is locking it.

Have a D30 with 4.56s a stock drive shaft and a nvg241or.

In 4wheel everything works as it should.

But in 2wheel turning 90* and a little less the front wants to engage and really bucks the front end. If i pull the front shaft all this stops and the locker acts like it should in 2wheel. No feeling and sometimes hearing it click. The drive shaft joints are nice and free and so is the center ball. The tcase is really in 2wheel and i have no rotation when up on stands. The pinion drag is fine and well within spec. The carrier speced out great with the locker installed and i have checked it twice after the frist install.

Its almost like the spring in the locker are to stiff and the drag from the driveshaft is locking it.